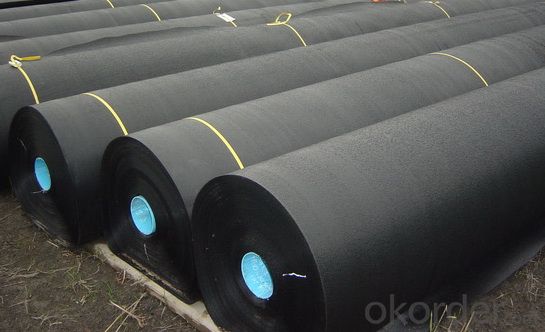

Geotextile Membranes - Waterproofing Polypropylene Needle Punched Geotextile Membrane Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Introduction

HDPE Smooth Face geomembrane are the preferred products for lining projects requiring low permeability , corrosion protection ,

exceptional chemical and ultraviolet resistance properties , which makes them extremely cost

effective for many applications such as waste landfill , storage reservoirs ,canals , powr plants in energy , vapor barriers ,

and waste water treatment in the line of industry and aquaculture and agriculture projects.

Features

•Easy process and high output rates

•Excellent distribution of carbon black

•Consistent quality and low failure rate

•Excellent resistance and good waterproof ability

•Good welding

Application

1. Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2. Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3. Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4 .Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5. Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6 Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help in sediment control?

- Geotextiles help in sediment control by acting as a physical barrier that traps sediment particles while allowing water to pass through. This prevents erosion and sediment runoff from construction sites, roads, or other areas, thereby reducing environmental pollution and protecting water bodies from sedimentation.

- Q: How do geotextiles help in preventing differential settlement?

- Geotextiles help in preventing differential settlement by providing a stable base for the soil beneath structures. They distribute the load more evenly, reducing any differential movement that can cause settlement.

- Q: Can geotextiles be used in the construction of landfills?

- Yes, geotextiles can be used in the construction of landfills. Geotextiles are often used as a barrier or liner material in landfills to help prevent the migration of contaminants and control the flow of leachate. They are commonly used to enhance the stability, durability, and environmental performance of landfill systems.

- Q: Geotextile with ordinary non-woven like not? The

- Geotextiles are warp.

- Q: Geotextile seepage seams how to deal with

- First geotextile is not waterproof, you say is a composite geomembrane, seams with a welding machine welding, can also use ks hot melt welding. Huazhi engineering materials manufacturers to answer your questions

- Q: I only know how many grams per gram of geotextile, but do not know what the meaning of this TS30? More

- Product specifications: equivalent to weight 126g / m2

- Q: Geotextile now how much money? what is the price?

- Is to be based on market conditions, raw material prices, processing technology to determine the price of geotextile to Hongxiang Li Qian short wire geotextile, for example, t price is generally between 4900-7500 yuan / ton, but the weight of <200g , An increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan / ton. 187 & lt; 6600 & lt; 5604

- Q: Concrete pavement or geotextile

- Do not add, with the asphalt Ma plug Seal if you have to choose the best choice for geotextile waterproof the best

- Q: Production of acupuncture carpets, geotextiles, warm flakes, paper blankets, air filter materials, the main raw material is what? why?

- Fiber, like eating bread must be the same with the face

- Q: How do geotextiles contribute to the performance of geogrid-reinforced slopes?

- Geotextiles contribute to the performance of geogrid-reinforced slopes by providing separation, filtration, and reinforcement. They act as a barrier between the soil layers, preventing the mixing of different materials and maintaining the integrity of the slope. Geotextiles also help with filtration by allowing water to pass through while preventing the movement of fine particles, which can clog the geogrid. Additionally, geotextiles enhance the reinforcement provided by geogrids by distributing the load and reducing localized stress concentrations, improving the overall stability and performance of the slopes.

Send your message to us

Geotextile Membranes - Waterproofing Polypropylene Needle Punched Geotextile Membrane Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords