Hydraulic Auto-climbing Formwork from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

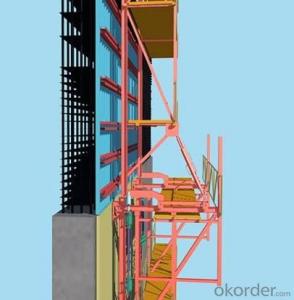

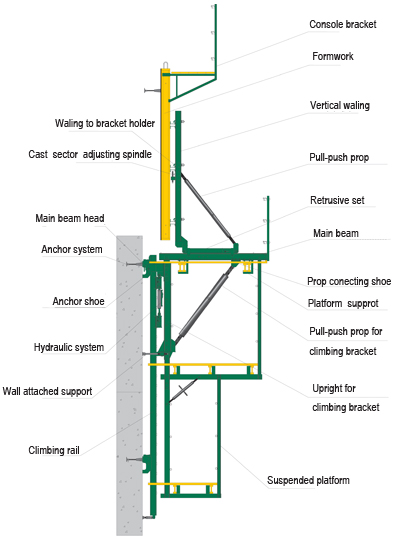

The power of the auto-climbing formwork is the hydraulic system, which includes the oil cylinder and commutators. Through the functioning of hydraulic system, the steel rail and bracket can climb up alternately,The commutators can control the climbing of the climbing rail and the bracket. The steel rail and the bracket can inter-climbing, so the whole system will climb up steadily. Cranes are not needed during the construction. It' s easy to operate, and climbing is fast and safe.

Product Characteristics

1. Perfect load bearing anchor system.

2. Crane-independent

3. One oil cylinder unit can lift 50KN.

4. The QPMX-50 system can climb not only vertically but also slantwise, and the forward or backward inclination can be up to 18 degrees.

5. The system can climb up wholly or separately. The climbing process is steady, synchronous and safe.

6 .The bracket does not come back to the ground until construction work is finished, and spacing for work is reduced while the bumping damage is almost completely prevented, especially for the plywood.

7.The error of structure construction is tiny and easy to correct.

8.The formwork can climb up by itself and cleaning work can be done in situ. The number of crane lifts are greatly reduced.

Climbing Process Introduction

1.Set up the formwork by wall-through tie-rods and pull-push props, embed anchors and do the first concrete pouring.

2. Remove the formwork after the first pouring and fix anchor shoes on the finished wall, lift the brackets and formwork to the right position, match the formwork and do the second pouring.

3.Lift formwork and brackets to the higher floor; fix climbing rail and hydraulic system.

4.Match the formwork to the right position and do the third pouring.

5.Strip the formwork and fix anchor shoes on the finished wall, then let the climbing rails climb.

6. Brackets climb up to the right position, then install suspended platform.

7.Match the formwork, do the concrete pouring, and proceed into the standard climbing stage.

- Q: How is the hydraulic support moving

- Hydraulic support shift method: push the jack extension, push the rod out, push the scraper conveyor forward a step, and then move the jack close, push the lever to take back, scraper conveyor reaction on the bracket, driving the stent forward a step Distance, complete hydraulic support shift frame.

- Q: Climbing and floor scaffolding advantages and disadvantages

- Floor scaffolding: Advantages: bearing capacity. When the scaffolding geometry and construction in line with the relevant requirements, under normal circumstances, scaffolding single tube column bearing capacity of up to 15kN ~ 35kN (1.5tf ~ 3.5tf, design value).

- Q: What is a climbing frame?

- Taosheng Technology TOSUN as the leading research and development, production, sales, leasing and construction units in China, is committed to providing customers with comprehensive construction safety protection solutions.

- Q: Is the scaffolding scaffolding?

- Climbing frame, also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building.

- Q: Climbing several, how is it running? And how much is the rental fee? Please explain in detail master! Thank you!

- Set the mounting platform --- Place the base, install the rails, assemble the horizontal truss parts - connect the beams to the rails with bolts and fasten the main frame to the beams - On the beam - the installation of wall-mounted device, the frame unloading to the guide seat --- with the structure connected to the elevated body, erected scaffolding, laying the middle layer or temporary scaffolding --- and the building structure to do temporary frame Pull the connection, hanging out the top of the safety net --- installed after the third beam, the installation of lifting seat and a layer with a wall guide block --- then the main frame of the main frame, the frame erected to the design height, Laying the top scaffolding plate, foot plate --- laying the bottom of the safety net and scaffolding, the production of flap - the upper frame and the structure of the effective pull-pull (pull-pull spacing of not more than 6m) --- hanging outside the row of dense security To the top of the frame --- the anti-fall boom inserted into the base anti-fall device, install the lifting wire rope --- placed electric control cabinet, distribution cable, install electric hoist, wiring, commissioning electrical system --- preload electric gourd, inspection and acceptance, with removal of the upper frame structure then pull, lift one synchronization --- fully installed, into Upgrade cycle

- Q: The difference between climbing and sliding mode

- Climbing is a short form of climbing template, also known as jumping abroad. It consists of climbing template, climbing frame (and some climbing no climbing) and climbing equipment composed of three parts, in the construction of shear wall system, the cylinder system and bridge pier and other high-rise structure is an effective tool. Because of the ability to self-climb, so no lifting machinery lifting, which reduces the construction of transport machinery lifting workload. Climbing scaffolds on self-climbing templates eliminates the need for external scaffolding during construction. In summary, climbing the template can reduce the number of lifting machinery, speed up the construction speed, so the economic benefits are better. Slip mode is a slow moving structure of the template, usually a fixed size of the stencil, drawn by the traction device.

Send your message to us

Hydraulic Auto-climbing Formwork from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords