High Strength Asbestos Free Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

High Strength 100% Asbestos Free Calcium Silicate Board

+ Good Quality But Competitive Price

+ Fireproof and Water Resistant

High Strength 100% Asbestos Free Calcium Silicate Board

Product Advantages:

Non Asbestos, Anti Fungus.

High quality raw material and fiber.

20 years warrantee.

Durable, hard to deform.

Low in thermal movement i.e. low shrinkage.

High strength, light weight

Widely used in Hospitals, Hotels, Schools, Offices, Subways, and Laboratories

Standard Size: 1220mm*2440mm / 4'*8'

Thickness: 3mm to 18mm

Surface Hardness: 3H

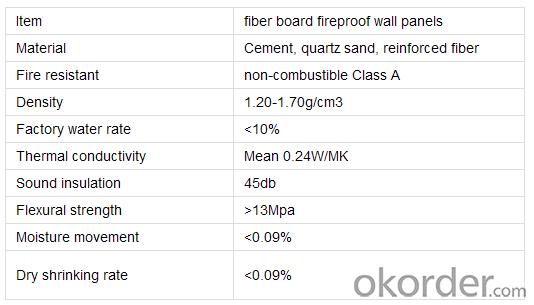

Main Product Features:

(Item) | (Unit) | (Result) | (Standard) |

(Density) | g/cm3 | 1.6 | 1.4<D<=1.7 |

(Weathering Test) | 4 | 3<=W<=5 | |

(Flexural Strength) (Dry) | MPa | 19.5 | >=18 |

(Flexural Strength)(Saturated) | Mpa | 16.5 | >=14 |

(Water Absorption) | % | 19.6 | <=25 |

(Wet Expansion) | % | 0.176 | <=0.23 |

Product Specifications:

Images:

- Q: What is the use of high-temperature calcium silicate board? I want to find a material can be resistant to high temperature 1500 ℃, and must be pressure,

- Chemical composition has long been changed, the intensity is certainly lost, do not say that fight against, there are problems with compression. Calcium silicate does not meet this requirement

- Q: Calcium silicate board and noise board which sound insulation effect is good

- Sound insulation board is collectively, calcium silicate board is a product name, calcium silicate also has calcium silicate sound insulation board, but you look and what kind of board than the best effect of wood should be good

- Q: Home improvement ceiling with a special board, scraping the cover is a good place is rural?

- Then come back to ask questions. Usually the national standard is low, we Ete's corporate standards to be higher than the national standard. Etter board thickness has a lot of 6-12mm range. But for the ceiling is also due to project vary. Some room ceiling related to fire protection requirements, then we usually choose low-density series 8mm or 10mm; some just a simple office ceiling, then the medium density of 6mm can be Edite board is not calcium silicate board. The name of the Aite plate is a fiber-reinforced silicate plate. The board is imported from the plant fiber, not the ordinary calcium silicate board.

- Q: Is the calcium silicate board attached directly to the wall?

- Yes, but the premise is that the wall must have a good flatness, otherwise, after the installation of the surface will be uneven.

- Q: What is the amount of tropicin in the calcium silicate board? Or how to define? What is the effect of the content on the quality of calcium silicate board?

- So that calcium silicate board is actually Tremere to stone crystal with fiber reinforced. If the reaction is incomplete in the autoclave, the formation of the beta-tropicite crystals is not enough, resulting in a sharp decline in the strength of the calcium silicate board, and even cause waste (soft plate).

- Q: Fiber reinforced powder quartz calcium silicate board and powder quartz calcium silicate board is what is the difference

- Calcium silicate board (English: calcium silicate) as a new green building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, a large number of industrial and industrial buildings used in ceiling ceilings and Partitions, home furnishings, furniture linings, billboard linings, shipboard trays, warehouses, floorboards, and tunnels.

- Q: Gypsum board, Etter board, calcium silicate board, mineral wool board physical properties of what is different, the kind of hotel for the ceiling is more appropriate?

- Ette board for the tile wall, calcium silicate board is better, but the cost is certainly better than the gypsum board, in order to economic effect, the effect is good, with gypsum board

- Q: Does the calcium silicate factory pollute? What is the harm to people? Please know the big god reply! Thanks

- Environmental hazards are dangerous to people's health

- Q: Calcium silicate board can be ground?

- Yes, you can ceiling, floor, etc. are possible, calcium silicate board light, waterproof, sound absorption is very easy to use

- Q: What is the difference between silicon calcium and cement fiberboard?

- Two are completely different products, in the national industry standard number also belong to different product categories: fiber cement pressure plate number is JC / T412, calcium carbonate board number is JC / T564. Then the two have the same point, what is the difference

Send your message to us

High Strength Asbestos Free Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords