Non Asbestos Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Calcium Silicate Boards) Description

Calcium Silicate Board is mainly made of siliceous and calcareous materials

as major and natural cellulose reinforced, forming in Hatschek process and high

pressure (7000 tons and fumigation(in autoclave for 24 hours),Which has the advantages

ofhigh strength, light weight, anti- freeze, water-resist, fire-proof, damp-proof, sound-absorption ,

no distortion and no radiation Used assuspended ceiling, partition, heat insulating board,

base plate, external wall panel, exterior wall cladding, paneling, flooring, back-liners, skirting lines,

prefabricated structures, door shutters

2,Main Features of the (Calcium Silicate Boards)

Application: partition & ceiling in office, supermarket, hotel, hospital, gymnasium, school, stations;

interior wallboard in carriage, marine structure, shipping vessel which need fire-proof, heat insulation and damp-proof

Materials: Tobermorite, lime, Quartz sand, wood fiber

Fire-proof rate: A-class incombustible (GB8624-1997)

Incombustibility: 240 minutes (GB/T9978-1999)

Density: 1.2-1.4g/cm3

Moisture:<10%

Heat conduction: 0.24W/MK (Jc/t564) Average

Sound-absorption: 45db (GBJ75-84)

Anti-bend strength: >15MPa (GB/T7019-1997)

Moisture movement rate:<0.19% (GB/T7019-1997)

Product Description

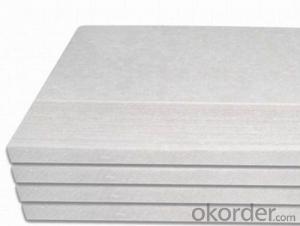

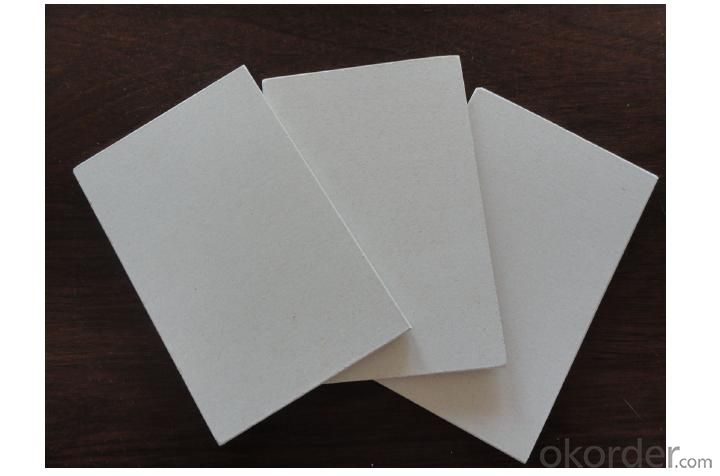

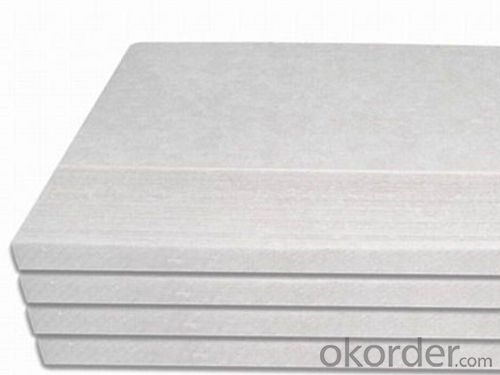

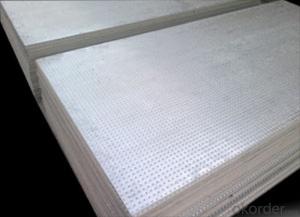

3,(Calcium Silicate Boards) Images

4,(Calcium Silicate Boards) Specification

Size & Loading Quantity of Calcium Silicate Board:

| Thickness (mm) | Length x width (mm) | PCS/ 20GP | Surface |

| 5mm | 1200mm x 2400mm 1220mm x 2440mm | 1050 PCS /

| Single, double surface Sanding or tapered |

| 6mm | 1200mm x 2400mm 1220mm x 2440mm | 880 PCS /

| Single, double surface Sanding or tapered |

| 8mm | 1200mm x 2400mm 1220mm x 2440mm | 656 PCS /

| Single, double surface Sanding or tapered |

| 9mm | 1200mm x 2400mm 1220mm x 2440mm | 588 PCS /

| Single, double surface Sanding or tapered |

| 10mm | 1200mm x 2400mm 1220mm x 2440mm | 520 PCS /

| Single, double surface Sanding or tapered |

| 12mm | 1200mm x 2400mm 1220mm x 2440mm | 442 PCS /

| Single, double surface Sanding or tapered |

| 15mm | 1200mm x 2400mm 1220mm x 2440mm | 346 PCS /

| Single, double surface Sanding or tapered |

| 18mm | 1200mm x 2400mm 1220mm x 2440mm | 294 PCS /

| Single, double surface Sanding or tapered |

| 20mm | 1200mm x 2400mm 1220mm x 2440mm | 260 PCS /

| Single, double surface Sanding or tapered |

Customized sizes and thickness are also produced.

5,FAQ of (Calcium Silicate Boards)

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing.

- Q: Do the TV backdrop, there is a part of the original window, now sealed with calcium silicate board.

- You can use wallpaper, marble, diatom mud will do. If the use of marble recommended dry hanging, because the grass-roots calcium carbonate plate has a water absorption, can not achieve the condensation strength.

- Q: Calcium silicate board production line

- Flow slurry method is equipped with a stirrer and separator in the headbox. When the slurry reaches a certain level in the headbox, it flows naturally through the horizontal cloth pulp plate and the inclined flow slurry plate to the blanket to form the initial material layer, The initial material layer through a number of vacuum box forced dehydration, winding to the forming tube I, to achieve the required thickness from the molding tube after pulling the wet blank, the next process into a variety of products.

- Q: Calcium and calcium silicate board and calcium carbonate plate distinction and contact

- Smallpox modeling Less use of calcium silicate board. hardness. Moisture, waterproof. Deformation. Better performance on fire. 2 price is not much.

- Q: How to distinguish between the color of calcium silicate board is good or bad

- Identification of calcium silicate board with fire: Calcium silicate board is a fire board, so the direct use of a well-burned plate, then there is no role. Before the fire must use the way to get the plate, pay attention, do not directly use the saws saw, if it is thin, hand directly snapped, if it is thick plate, use the hammer to break it. After the break, you will send now cross-section inside covered with small lines, these small lines or that is asbestos, or that is the plant fiber, if it is asbestos, then burned after the announcement will affect the burning smell, If it is plant fiber, then burned after the paper will announce the taste of burning. A smell can easily distinguish this calcium silicate board is not rich in asbestos.

- Q: What is the difference between aluminum-plastic plate and calcium-plastic plate? How to use it in those places?

- In any country, calcium silicate boards are non-combustible materials, some countries will be classified as statutory fire plate. In China, the Ministry of Public Security will calcium silicate board as fire control materials, calcium silicate board can almost all through the "noncombustible A-level" test. In the construction site where the fire requirements are required, the use of paper gypsum board often requires the use of several plates to achieve the required fire protection requirements, and calcium silicate board generally only one third of the thickness to meet the fire requirements. In contrast, calcium silicate board performance is better

- Q: Where to produce 3 m long reinforced fiber calcium silicate board

- Fiber reinforced calcium silicate board is a new building decoration material from 2011 to 2012. The fiber reinforced calcium silicate product has the advantages of light high strength, fireproof insulation, durable, low shrinkage rate, good processing performance and easy surface decoration. , Is widely used in building interior and exterior decoration, ventilation pipes, sound-absorbing panels, fire wall panels and a variety of special-purpose industrial facilities

- Q: 6.5 square machine room decoration ceiling how to count? Ceiling using calcium silicate board + steel keel, remove, block 8 nozzle

- Artificial 40 square meters. Material 35 square meters. A total of 480 yuan ceiling, demolition, blocking and the like, a total of 200 yuan. Paint paint is 25 square meters (including labor) a total of 150 yuan. A total of 850-900 yuan can do a good job

- Q: Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- Install the main keel 1> equipped with boom pheasant 2> Install the pendant on the main keel 3> Install the main keel: the main keel will be assembled hanging pendant, according to the location of the sub-line to hang the hanging pieces into the corresponding ring bolt. 4> main keel connected with the installation of connectors, pull the line to adjust the elevation, from the arch and straight. 5> around the keel with nailing Hong Ding set. Design no requirements, the nail spacing of 1000mm.

- Q: What is the use of calcium silicate board with calcium silicate board ceiling is good

- Calcium silicate board is a new generation of "green" building materials, in the excellent moisture, fire performance based on the unique environmental protection features. It is based on silicon powder and calcium powder as the main substrate, with natural wood fiber as a reinforcing material, mixed with other auxiliary materials, through the flow slurry molding, in the high temperature, high pressure conservation of a new building materials.

- Q: I need a tool that can cut calcium silicate board, Bo deep good, where can I buy Wuxi?

- You can go directly to their manufacturers to order, and then let them express to you

Send your message to us

Non Asbestos Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords