Panels Calcium Silic Board With ASTM Standard

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

Calcium Silicate Board has superior performance, dimensionally stable and requires low maintenance. A perfect balance between durability and workability, give you both strength and flexibility to build quality, beautiful, and well-designed homes.

Indoor ceiling of industrial and resident building.

Partition of industrial and resident building.

The ceiling and partition of the bathroom and other wet condition building.

Product Advantages:

Indoor ceiling and partition as base board of the decoration for the operating room, clean room of hospital.

Indoor ceiling and partition as base board of the decoration for the operating room, clean room of Laboratory.

The fireproof board of the air passage.

Furniture or furniture’s accessories.

Main Product Features:

Calcium silicate base board is manufactured from Portland cements; Lime; Quartz; Cellulose fiber; additives and water. It does not contain asbestos, brucite , meerschaum, glass fiber and formaldehyde.

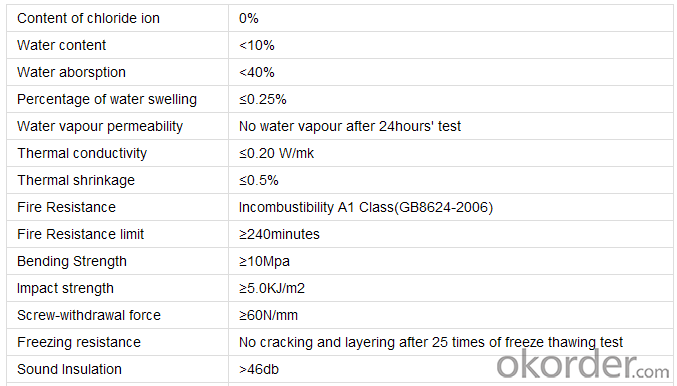

Product Specifications:

Images:

- Q: Calcium silicate board can be used in the roof

- Silicon calcium board, also known as gypsum composite board, which is a porous material, with good sound insulation, thermal insulation properties, in the case of indoor air humid to attract water molecules in the air, air drying, but also the release of water molecules, Appropriate to adjust the indoor dry, humidity, increase comfort.

- Q: Calcium silicate board and magnesium silicate board which is better

- In recent years, with the improvement of production technology, the use of calcium silicate board is also more and more common in Guangdong, in addition to the external brand of Etterit, there are Oulang, Jinfu, Chun Figure, Yin Xing and other own Brand.

- Q: Is the calcium silicate board gypsum board?

- But the gypsum board fire and water resistance is weak, it is being replaced by calcium silicate board. In price, the price of calcium silicate board is also slightly more expensive than gypsum board, but it is worth the money.

- Q: Calcium silicate board production line

- Calcium silicate board production line by the ingredients machine, pulp machine, slurry tank, mixer, plate machine, blank machine, stripping machine, steam curing machine, dryer and milling machine, with the conveyor, conveyor composition Complete fiber reinforced calcium silicate board production line. The production line with high efficiency, low energy, high capacity, economic and reasonable advantages.

- Q: Door head decoration, outside the aluminum-plastic plate which can be used calcium silicate board?

- General 2-3M of the door are no problem. As well as look at your door on the decorative effect, anyway, is not too heavy!

- Q: What is the size and classification of calcium silicate board? How do we choose the specifications for their own calcium silicate board?

- Calcium silicate specifications are conventional specifications, that is, 1220x2440, or the use of conventional specifications more money, you want to be more expensive

- Q: Is calcium carbonate board containing asbestos poisonous?

- There is micro-toxic, calcium silicate to stimulate the eyes and respiratory system, asbestos itself is not toxic, its greatest harm from its dust, when these small dust is inhaled into the body, will be attached and deposited in the lungs, causing the lung Department of disease, asbestos has been recognized by the International Cancer Research Center for carcinogens.

- Q: What is the difference between the board and the silicon board?

- Et board is also known as calcium silicate board. Silicon calcium board is based on the improvement of gypsum board products

- Q: Calcium silicate board with asbestos and non-asbestos how to choose

- In the real life of the decoration of the procurement staff, some are on the building materials how to understand, especially those construction units, many of the construction of the College of Engineering materials is also a little knowledge, so that caused by the misunderstanding of building materials, On the current calcium silicate board, basically divided into two kinds, one is decorated with, and the other is the ceiling with the

- Q: What is the difference between calcium silicate board and mineral wool board?

- In terms of health and environmental protection, mineral wool board mineral wool dust particles are easy to inhale the human body, and high carcinogenic substances; Calcium silicate board It is made of siliceous material (diatomaceous earth, bentonite, quartz powder, etc.), calcium material, reinforced fiber as the main raw material, cutting dust In terms of cost, mineral wool board the cheapest, calcium silicate board price center.

Send your message to us

Panels Calcium Silic Board With ASTM Standard

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches