water resistance wpc flooring. High quality, CE certificate, wood plastic composite decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

water resistance wpc flooring. High quality, CE certificate, wood plastic composite decking

一.Product Description:

synthetic wood flooring/wpc decking From China

High Quality Supplier Looking For Partner

35% HDPE (Grade A Recycled HDPE),

55% wood fiber (Professionally treated dry wood fiber),

10% chemical additives (Anti-UV agent, Anti-oxidation agent, stabilizer, colorants, anti fungus agent, coupling agent, reinforcing agent, lubricants...etc.).

Features

1.Looks and feels like nature wood

2. Waterproof, Mildew-resistant

3.Anti-High degree of UV and colour stability

4. No hazardous chemicals,100% recycle,Environmental friendly,Saving forest resources

5.weather resistant,Suitable from -40'C to 60'C

6. Easy to install and clean

7. Unaffected by termites and other insects, rodents,worms or marine parasites

8. Low maintenance cost

9. Anti-slip, less cracking, less warping

High Quality Supplier Looking For Partner

35% HDPE (Grade A Recycled HDPE),

55% wood fiber (Professionally treated dry wood fiber),

10% chemical additives (Anti-UV agent, Anti-oxidation agent, stabilizer, colorants, anti fungus agent, coupling agent, reinforcing agent, lubricants...etc.).

Competitive Price

• Using most advanced machinery to increase the output and reduce the costs.

Strong technical support from famous institute of high polymer to guarantee the best quality as well as cost saving.

• Neighboring one of the biggest wood/ bamboo processing industry region and having a special purchase channel of the raw materials (Plastic and wood/bamboo fiber)

• As a high technology and environmental-friendly enterprise, supports form the government such as reduction and exemption of tax rate are available.

escriptions :

The characteristics of Wood generally had the problem of Waterproof and the serious concern to the environmental protection has been increasing day by day as well as it caused the Governments worldwide to stipulate the law to restrict to fell trees to reach the goal. To satisfy with the market's demand we utilized the characteristics of macromolecule to combine with the high technology of heavy pressure-micro foaming to produce an unique product with the invention and innovation of revolution. We call this new product " CELLwood®".

Properties :

1. 100% recyclable product meets with the environmental protection without

adding any wood flour or sawdust.

2. 100% waterproof.

3. Suitable to be used for the activities indoor and outdoor.

4. The component with high quality features that the density is similar to the wood

(D:0.6~0.7 g/cm3) and light.

5. The processing is similar to the general timber, e.g.: shave, saw, trim, nail, drill,

wash and grind.

6. Strong rigidity and durability. (Similar to teak)

7. Thermal process is easily executed to be blended to have various shapes of the

materials.

二.Technical Data

Slip resistance:

Boards of Techwoodn according to ASTM D2394-05. This is the best ranking for bare-foot slip resistance.

Weathering resistance:

Boards of Techwoodn have very low moisture uptake.This is key for mold and mildew resistance.

UV resistance:

4000 hours accelerated Xenon-arc Exposure,the Boards turned slightly more clear and colored.

Abrasion resistance:

The resistance to abrasion is similar to oak.

Fungus resistance:

Whatever fungus the wood composite is exposed to,it is extremely durable.

Moreover,aging test does not affect this durability.

三. FAQ

. What kinds of wpcproducts do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

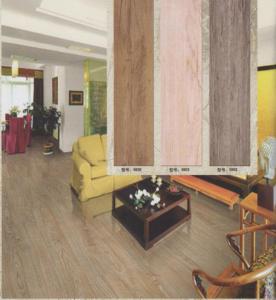

四. More picture for your reference

- Q: What is the thickness of the anti-skid tiles?

- 10MM or so.

- Q: Okay, I have been wanting to turn my garage into a dance studio for a while. I have checked in to marley flooring and it is so expensive. I don't want to get the 'home studio kit' and don't want wood flooring. So where can I find cheap marley flooring? Thanks :)

- I frequently spend my half an hour to read this blog's posts daily along with a mug of coffee.

- Q: We have a BIG island in our kitchen and an empty wall behind it.Our flooring is a laminate type. We want to remove the island and put a row of cabinets along the wall. My questions are: Are cabinates installed on top of the laminate flooring? If not, how do we remove the flooring along the wall and possibly use those boards to patch the spot where the island was? We really Hate this island. Any help would be greatly appreciated.

- Look at where the island and laminate meet. Does it look like the laminate goes under or is their molding at the base of the island. I would also guess that the laminate goes around the island. Laminate boards connect on the ends as well as the sides. You willl not simply be able to insert board to filll the hole, to do it right you will have to reset the boards the entire length. Also, what are you going to do to replace the laminate that you pull off that is against the wall? Sorry to be a pain but i just wanted to know what you are up against before ridding yourself of the island.

- Q: I am nearing completion of construction for my own new 2 story home. On the 2nd floor, I am planning to install a floating bamboo floor (5/8" stranded type) over gypcrete (lightweight concrete floor poured over radiant in-floor heat tubing. I think I can handle most everything, but I am not certain what the best option(s) is for running the floating floor into the staircase which goes down to the first floor. In the rest of the house, the edge of the floating floor will get covered by baseboard, but at the top step, there is no such option. Does anyone have suggestions as to the best way to deal with this? One more thing - it's tongue and groove and I was planning to glue the boards together. I already have the flooring and there are stairnosings I have with a groove on them which I was planning on assembling with the planks to cover the stairs too.

- Just make sure you don't create a tripping hazzard. Purchase a hardwood stair nosing to match your stair treads (Oak?). Then make sure that the nosing hangs past the stair riser the same as the others. It will probably be Thicker than the flooring but you can take it to a local cabinet shop and have them cut a rabbett ( an offset) in it . Good Luck

- Q: Another laminate flooring question.I am laying this floor in a family room which has a total of 7 doorways. What is the best method of installing this kind of floor along(not through) doorways?

- I agree with laying the board flat and tapping it together. Use a scrap piece of flooring to tap on that is laid against the board being tapped together. This way you will not damage the board.

- Q: 1) Show that, for any real number x, the expression "ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] always equals either floor(x) or ceiling(x). In what circumstances does each case arise?I think it equals floor(x) when x is negative and ceiling(x) when x is positive, but I can't do the general proof.Background information: Floor of a real number x = the largest integer less than or equal to xCeiling of an real number x = the smallest integer greater than or equal to x-floor(x) = ceiling(-x)if x is an integer then floor(x)=ceiling(x)

- If x=2k, k∈?, ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] = = ceiling[2k + 1/ 2] - ceiling[k + 1/4] + floor[k + 1/4] = = (2k+1) - (k+1) + k = 2k = x = floor(x) = ceiling(x). ---------- If x=2k+1, k∈?, ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] = = ceiling[2k + 1] - ceiling[k + 1/2] + floor[k + 1/2] = = (2k+1) - (k+1) + k = 2k = x = floor(x) = ceiling(x). ---------- If 2k < x ≤ 2k+1/2, k∈?, = 2k+1/2 < (2x+1)/2 = x+1/2 ≤ 2k+1 = ceiling[(2x+1)/2] = 2k+1 and k+1/4 < (2x+1)/4 = x/2+1/4 ≤ k+1/2 = ceiling[(2x+1)/4] = k+1 floor[(2x+1)/4] = k Then ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] = = (2k+1) - (k+1) + k = 2k = floor(x). ---------- If 2k+1/2 < x < 2k+1, k∈?, = 2k+1 < (2x+1)/2 = x+1/2 < 2k+3/2 = ceiling[(2x+1)/2] = 2k+2 and k+1/2 < (2x+1)/4 = x/2+1/4 < k+3/4 = ceiling[(2x+1)/4] = k+1 floor[(2x+1)/4] = k Then ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] = = (2k+2) - (k+1) + k = 2k+1 = ceiling(x). ---------- If 2k+1 < x ≤ 2k+3/2, k∈?, = 2k+3/2 < (2x+1)/2 = x+1/2 ≤ 2k+2 = ceiling[(2x+1)/2] = 2k+2 and k+3/2 < (2x+1)/4 = x/2+1/4 ≤ k+1 = ceiling[(2x+1)/4] = k+1 floor[(2x+1)/4] = k Then ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] = = (2k+2) - (k+1) + k = 2k+1 = floor(x). ---------- If 2k+3/2 < x < 2k+2, k∈?, = 2k+2 < (2x+1)/2 = x+1/2 < 2k+5/2 = ceiling[(2x+1)/2] = 2k+3 and k+1 < (2x+1)/4 = x/2+1/4 < k+5/4 = ceiling[(2x+1)/4] = k+2 floor[(2x+1)/4] = k+1 Then ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] = = (2k+3) - (k+2) + (k+1) = 2k+2 = floor(x).

- Q: Who knows the biggest size of the tile is how much?

- The specifications are very small, look at the introduction of ceramic anti-static flooring and anti-static tiles, apply to the need for high wear-resistant high-rise floor of the occasion Direct-type anti-static tiles for computer room, microelectronics plant, production and installation workshop, laboratory And other places have a dustproof, anti-static requirements 1. Product Description Anti-static tiles using high-tech, wave of brick body body Duan tripod scraping calcium water sting, add a special anti-static powder, high temperature sintering; Anti-static performance is stable, durable (resistance guaranteed at 107Ω). The use of conductive ground anti-static tiles installation process, and a reasonable grounding system design, access to reliable anti-static performance. Antistatic tiles can be used as an active floor of the floor (instead of ordinary HPL veneer and PVC veneer), can also be laid directly on the ground as an anti-static ground. 2. Product features non-combustible; permanent anti-static; rich color, high dimensional accuracy, good flatness; wear, long life; can not afford dust; easy to clean maintenance, no wax; anti-static tiles completely put an end to the ordinary HPL and PVC paste Face tilt, broken, easy to clean up the problem, is a rapid development of replacement products.

- Q: - to the whole ,,, the best not only the beginning. - I search a bit, the site of the floor to induce the small Ding shares Ding Ji Ding Ding Ding stabbed inside the puzzle there are "5" the number ... ... - Will the 8K or 4K inside there are no "5" this

- MM floor temptation step level6 = level7 = 729level8 = 299 Fu Ding brother shares Xi Jiadian tied Ding stem level9 =

- Q: I am remodeling my kitchen and it has an industrial tile on the floor now (similiar to school flooring). I would like to put ceramic tile in its place. is it okay to lay the ceramic right over top if the floor is in good condition? or do i have to remove the laminate before placing the ceramic?

- Lift the laminate. You'll need a rougher surface to properly lay the ceramic tile.

- Q: I have laminate floors and someone told me to use swifter wet jet but it kind of leaves streaks so I would like something that leaves my floors nice and shiny. Any suggestions?

- Hi, I just use warm water and vinegar 1 cup to a gallon. It works well and I prefer something that is natural. I just use a mop that is well wrung out so it is just damp. You do not want to wet floors. I sometimes buff up with a towel attached to my swifter. Soap-based products and citrus based products leave a residue on laminate making them look dull. It may take a few washings to get rid of the film. It is good to use warm water as it evaporates more quickly.

Send your message to us

water resistance wpc flooring. High quality, CE certificate, wood plastic composite decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches