Waterproof Wood Plastic Composite Decking Anti UV WPC Flooring High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Waterproof Wood Plastic Composite Decking:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

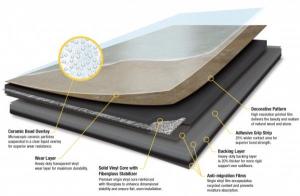

Composition of Waterproof Wood Plastic Composite Decking:

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of Waterproof Wood Plastic Composite Decking:

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of Waterproof Wood Plastic Composite Decking:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of Waterproof Wood Plastic Composite Decking:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q: How to remove the plastic protective film on the floor angle

- There are three kinds of brick protective film:plastic filmBe able to gradually tear with the hand or be able to gently wipe with a steel ball.Antifouling protective filmThe protective film can be dipped in white cement with a towel.Ceramic tile protective filmBe able to scrub with a dry towel, scrub with an electric thinner or banana, and also use talcum powder and white cement.

- Q: How can a lot of plastic cloth stick on the wood floor?

- Remove the protective layer of the outer surface of the furniture, only the manual removal is the most convenient and effective method, with other things can easily hurt the appliance.

- Q: How to tear off the plastic film on the floor tiles

- To be transferred to the factory, in order to prevent damage to the floor during the renovation, in the brick surface have done a deal with the pollution, the general polishing brick made of anti fouling wax

- Q: What a pig with plastic floor to sell, how much money

- Plastic drain board for pigRaw material: polypropylene K8303 (referred to as PP) is non-toxic, odorless, tasteless milky white crystalline polymer, is currently one of the lightest varieties of plastic. Good molding, easy to color.

- Q: What is the role of the floor mat plastic sheeting

- Mainly moisture-proof insulation, to protect the wooden floor

- Q: Plastic foam flooring is not a large mosaic floor.

- When the children grow up, the floor needs to be replaced. What is the relationship between the damage to the floor, and then you can re paint it. Tiling can also be placed on the floor, you can let the children split up, spell the demolition, not much impact on the floor.

- Q: What is the home improvement PVC plastic floor

- Raw material and production process. The multi-layer composite sheet is composed of a bottom layer, a printing layer and a wear-resistant layer, and the quality of the three kinds of raw materials directly determines the quality of the plastic floor. Bottom layer: at present, the domestic manufacturers can use the bottom material can be divided into two categories, namely, new materials and recycled materials. However, the use of recycled materials produced plastic floor, its quality is not as good as the use of new materials flooring. The bottom material stepped up elastic strong, the water is not easy to deform, and is not easy to shrink, use a long time does not appear warped edge; and the recycled material made of bottom material almost no flexibility, the water will appear obvious swelling caused by edge tilt, if winter temperatures drop too fast will have obvious shrinkage thus, the influence of ground appearance. As consumers in general do not have the ability to distinguish the quality of the material, so we recommend that consumers buy branded products, do not covet cheap use of cottage PVC floor.

- Q: Badminton plastic floor? Want to be a sports venue, which plastic sports floor brand is better

- Badminton plastic floor is now used in indoor venues this1 at present, the major venues for badminton venues are designated laying plastic floor2 plastic floor and solid wood floor compared to: light weight, good elasticity, friction and other advantages3.KEMP champion badminton plastic floor is good, you can look at

- Q: What is the difference between plastic floor composite floor

- But it is expensive, hardwood resource consumption, the installation of heavy workload, difficult to maintain (fear of fire, fear of water, afraid of tide) and floor width direction produced larger size changes with changes in relative humidity.

- Q: Such as the title, do not know what is the real wood floor shop? The following is the keel I am looking for the materials and the advantages and disadvantages, we have what opinions and suggestions might as well talk about... 4, keel laid the keel: many materials, the most traditional is also plastic, wood keel, wooden keel and so on Aluminum Alloy 1): on the ground drill, fixed wooden keel, wooden keel on surface leveling the floor with a nail, will start...Home renovation renovation of the old house, the living room plus two bedroom only 41 square meters, which is more suitable for...In addition, the room is small, the shop is too thin and good-looking and consumption of materials, want to shop 455*90*1.8 or 455*120*1.8

- From the building materials, the use of plastic bar, simple and quick, economic. 15 years is no problemShop floor room 455*90*1.8 right

Send your message to us

Waterproof Wood Plastic Composite Decking Anti UV WPC Flooring High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords