PVC Laminated Tarpaulin

- Loading Port:

- Wuhan

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meter m²

- Supply Capability:

- 20 Container Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC laminated tarpaulin has been widely used as awnings, truck cover, tents, banners, inflatable products, materials for building facility and house. The width is from 1.00m up to 3.20m. The color can be customized according to customers' requirement. We can produce laminated and coated PVC tarpaulin, for its good flexibility, excellent tensile strength and tear strength, and they are easily to sustain long time for good performance.

Product characteristics of PVC laminated tarpaulin:

1.Excellent tensile ,tearing and adhesion strength.

2.Fire retardant, UV-protective, antimicrobia, oilproof, stain, acid and alkali resistance

3.Temperature and weather resistant, anti-oxidation and durable.

4.Printable.

5.For the production of tents, truck covers, awnings, and construction covers.

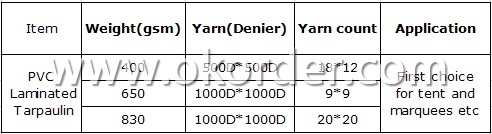

Typical Specifications of PVC laminated tarpaulin

- Q: Do you need a cushion on the ground floor?

- Chalet recommended to do sloping roof, the lowest point suggested 2.4. Talk about the ground, the roof, the wall area divided by the length of your board length and width of the area can be calculated on the amount of it!

- Q: Roof waterproof mattress should play the number of centimeters appropriate

- 4. The second layer to do mortar waterproof (mortar waterproof), waterproof at the same time can protect the bottom of the flexible waterproof.

- Q: Why do the basics of the cushion waterproofing

- Raft foundation do not do waterproof mainly depends on the design of the groundwater level considerations, calculated if the floor itself to meet the requirements, you can not do, and not rigid to do

- Q: The roof cushion is waterproof on the slope roof

- When the moisture generated by the ice dam into the external walls of the gap, the walls and insulation layer will become damp, which is the ideal environment for the breeding of mold.

- Q: Is it possible to make a waterproof layer

- 1, to do after the dry do, or prone to the phenomenon of wall skin off.

- Q: Is the raft cushion waterproofing full of the cushion?

- Assuming (just suppose) the raft can easily turn over, then we do waterproof (like roof) directly on it, not waterproof on the cushion.

- Q: Cushion, waterproof layer construction to do what information

- 2, bedding (bed course) refers to the structure below the grass-roots level. Its main role is to water, drainage, antifreeze to improve the grass-roots and soil-based working conditions, the water stability requirements are better. The cushion layer is a structural layer between the base layer and the soil base. When the soil quality is poor, it is used to improve the water stability of the soil base, improve the water stability and frost resistance of the pavement structure and disperse Load to reduce soil deformation.

- Q: What is the relationship between the cushion and the ring beam?

- Cushion is plain concrete or asphalt concrete (for groundwater soil corrosive strong site). Is located below the ground, in order to prevent the foundation or the concrete beam pouring when the excessive loss of water caused by defects set. The purpose is to ensure the quality of concrete, increase the durability of underground components

- Q: Why calculate the amount of time to count a lot of cushion ah

- Cushion cushion, as the name suggests is the structure of the liner layer, mainly from the back cover of the role, generally in the engineering design drawings have a clear approach (material).

- Q: Maintenance time of the cushion on the roof of the building

- Concrete watering maintenance time: the use of Portland cement, ordinary Portland cement or slag Portland cement mixed with concrete, not less than 7d;

Send your message to us

PVC Laminated Tarpaulin

- Loading Port:

- Wuhan

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meter m²

- Supply Capability:

- 20 Container Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords