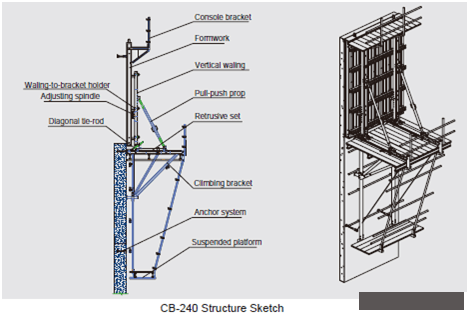

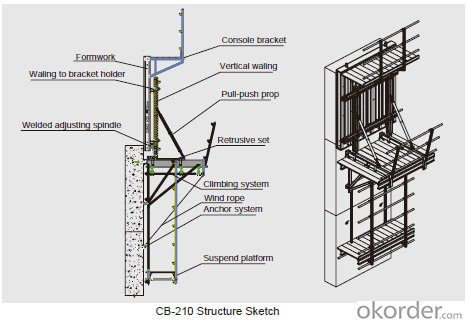

Vertical Structure Support System for Climbing Bracket CB240 & CB210

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Climbing Bracket CB240 & CB210

They are framework brackets for supporting large-area wall formwork.

Typical applications for the CB240&CB210 are pier and column/shear wall/core walll/ in the building.

CB210 has smaller size than CB240, it will be cost effective in some condition.

2. Main Features of Climbing Bracket CB240 & CB210

-High bearing capacity

-Simple moving procedure by crane

-Fast striking process without a crane

-Safe with work platform

3. Climbing Bracket CB240 & CB210 images

4. Climbing Bracket CB240 & CB210 Specifications

5. FAQ of Climbing Bracket CB240 & CB210

1) What can we do for you?

.We can ensure the quality of Climbing Bracket CB240 & CB210 and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

- Q: Are steel props commonly used in power plant construction projects?

- Steel props, also referred to as adjustable steel props or steel shoring props, are extensively utilized in power plant construction projects for their ability to offer stability and support during the construction process. These vital temporary supports play a crucial role in providing assistance to various structural components like beams, columns, and slabs. Their popularity stems from their remarkable load-bearing capacity, effortless installation and removal, and adjustable height feature, which enables flexibility in supporting diverse construction stages. Their exceptional strength and long-lasting nature render them a perfect choice for power plant construction projects, where safety and stability hold paramount significance.

- Q: How do you install and set up a steel prop?

- Follow these steps for the installation and setup of a steel prop: 1. Begin by assessing the area where the steel prop will be installed to determine the appropriate location. Ensure that the ground is stable and capable of supporting the prop's weight. 2. Next, select a steel prop that matches the required load capacity. Consider factors such as the height and weight that the prop needs to support. 3. Prepare the installation site by clearing away any debris or obstacles. It is important to ensure that there are no underground utilities or cables that could be damaged during the installation process. 4. Position the prop in the desired location, ensuring that it is aligned vertically. Adjust the prop's height to meet the required level or support needed. 5. Use a spirit level to check that the prop is perfectly vertical. Secure the prop in place using a steel prop clamp, ensuring that the clamp is tightened securely to prevent any movement. 6. If necessary, adjust the height of the steel prop to meet the required specifications. This can be achieved by extending or shortening the prop's telescopic sections. 7. Confirm that the prop is supporting the intended load and double-check the weight capacity to ensure it is not exceeded. 8. Conduct regular inspections of the steel prop to ensure it remains secure and properly aligned. Look out for any signs of damage or movement, and take immediate action to rectify any issues that are detected. Always refer to the manufacturer's instructions for the specific steel prop being used. If you are unsure, it is advisable to consult a professional or seek expert advice to ensure proper installation and setup of the prop.

- Q: Are steel props suitable for supporting temporary parking structures?

- Steel props are a suitable option for supporting temporary parking structures. They are also referred to as adjustable steel props or steel acro props and are commonly used in construction to support temporary structures like scaffolding, formwork, and shoring systems. These props are specifically designed to offer sturdy and stable support, while also being easily adjustable to the desired height. Made from high-quality steel, they possess durability and the ability to withstand heavy loads, which is crucial for parking structures. Moreover, steel props are effortless to install and dismantle, providing flexibility for temporary structures that may require relocation or removal after a specific period. All in all, steel props serve as a dependable and efficient solution for supporting temporary parking structures.

- Q: How do steel props compare to concrete slabs?

- Construction projects utilize steel props and concrete slabs as distinct components, each fulfilling specific purposes. Steel props, alternatively referred to as adjustable steel props or steel acrows, act as temporary supports, fortifying and stabilizing walls, columns, and beams during the construction process. Conversely, concrete slabs serve as horizontal structural elements, establishing the foundation or flooring of a building. When comparing steel props and concrete slabs, it is crucial to recognize that they are not interchangeable but rather complementary. Steel props primarily operate during construction, providing provisional support and guaranteeing structural stability. Their adjustable nature enables flexibility in aligning and reinforcing diverse construction elements. Moreover, steel props possess traits of lightness, ease of installation, and high load-bearing capacity, rendering them suitable for a broad spectrum of construction projects. Distinctly, concrete slabs function as enduring structural constituents, ensuring the stability and strength of a building. They are created by pouring concrete into formwork, allowing it to solidify and mature. Concrete slabs furnish a stable and robust foundation, evenly distributing loads and promoting stability. Furthermore, they offer benefits such as thermal insulation, soundproofing, and fire resistance characteristics. In conclusion, steel props and concrete slabs fulfill distinct roles in construction. Steel props serve as temporary supports, securing stability during construction, while concrete slabs act as permanent structural components, forming the foundation or flooring of a building. Both components are indispensable in ensuring the stability, strength, and functionality of a structure.

- Q: Are steel props adjustable for supporting inclined surfaces?

- Indeed, steel props possess the capability to adapt to inclined surfaces through their adjustability. Referred to as adjustable steel props or steel acrow props, these versatile tools can be altered in height by extension or retraction. This adaptability enables the props to cater to inclined surfaces by modifying their length accordingly. By securely placing the props on such surfaces, stability and support are effectively provided. Moreover, the props frequently incorporate adjustable heads that can be tilted to align with the angle of the inclined surface, further enhancing their suitability for supporting such structures.

- Q: Can steel props be used in temporary support of walls?

- Steel props are a viable option for temporarily supporting walls. These props, which can also be referred to as adjustable steel props or acrow props, are frequently utilized in construction projects to offer temporary support to walls, ceilings, and other structures during renovation or construction work. Their design allows for easy installation and removal, as well as adjustable height settings. Constructed from durable and robust steel, these props are capable of handling heavy loads. By providing stability and support, they guarantee that walls remain upright and secure during construction or repairs. In summary, steel props are a dependable and effective solution for supporting walls temporarily in construction endeavors.

- Q: Can steel props be used in basement construction?

- Yes, steel props can be used in basement construction. Steel props are adjustable and versatile temporary supports that are commonly used in construction projects, including basement construction. They are designed to provide temporary structural support during the construction process. Steel props can be used to support the weight of walls, floors, and ceilings, helping to ensure the stability and safety of the basement structure. Additionally, steel props can be easily adjusted to accommodate different heights and angles, making them suitable for various basement construction requirements.

- Q: What are the potential environmental impacts of using steel props?

- Categorizing the potential environmental impacts of steel props involves several areas. Firstly, the extraction of raw materials, like iron ore, for steel prop production can negatively affect the environment. Mining activities result in habitat destruction, soil erosion, and water pollution. Additionally, the refining and manufacturing process of steel consumes significant energy and releases greenhouse gases, contributing to climate change. Secondly, transporting steel props from manufacturing facilities to construction sites can have environmental consequences. Long-distance transportation necessitates the use of fossil fuels, leading to carbon dioxide emissions and air pollution. Furthermore, heavy transportation vehicles can damage roads and cause congestion, further impacting the environment. Moreover, the disposal of steel props after their useful life presents environmental challenges. Since steel is non-biodegradable, props often end up in landfills, contributing to waste accumulation and the consumption of valuable land resources. However, it is important to note that steel props can also have positive environmental impacts. Steel is highly recyclable, and recycling steel props can significantly reduce the need for new production and associated environmental impacts. Steel recycling also saves energy compared to primary steel production, as it requires fewer resources and generates fewer greenhouse gas emissions. To mitigate the potential environmental impacts of using steel props, several measures can be taken. Increasing the use of recycled steel is a crucial step towards reducing the demand for new production and conserving resources. Implementing energy-efficient manufacturing processes and utilizing renewable energy sources can also minimize the carbon footprint of steel production. Additionally, promoting sustainable transportation practices, such as optimizing logistics and using alternative fuels, can help reduce the environmental impact of transporting steel props. Overall, although steel props have environmental drawbacks in terms of their production, transportation, and disposal, their recyclability and potential for reduced energy consumption provide opportunities for mitigating their environmental footprint.

- Q: How do you prevent damage to steel props during construction activities?

- There are several measures that can be taken to prevent damage to steel props during construction activities. Firstly, ensuring proper training and supervision of workers is crucial, as they need to handle the props correctly and with care. Secondly, using protective measures such as placing rubber caps on the ends of the props can help prevent scratches and dents. Additionally, regular inspections should be conducted to identify any signs of wear or damage, and prompt maintenance or replacement should be carried out when necessary. Lastly, proper storage and transportation of the props, using appropriate equipment and techniques, can also help prevent damage during construction activities.

- Q: Can steel props be used in water treatment plant construction?

- Steel props, also referred to as adjustable steel props or steel shore props, can indeed be utilized in the construction of water treatment plants. These props are commonly employed in construction projects to temporarily support and stabilize structures. They possess the ability to provide vertical support and can be adjusted to accommodate various construction needs. In the context of water treatment plant construction, steel props fulfill a multitude of purposes. For instance, they can provide support to formwork during the construction of concrete structures like tanks, basins, and walls. Furthermore, steel props are ideal for temporarily supporting heavy machinery and equipment during installation or maintenance tasks. The utilization of steel props in water treatment plant construction is favored due to their inherent strength and durability. Crafted from high-quality steel, they are capable of withstanding the challenging conditions typically found in water treatment plants, including exposure to moisture, chemicals, and high humidity. Additionally, these props can be easily adjusted and securely fastened, ensuring precise positioning and alignment of structures, pipes, or equipment. Nevertheless, it is crucial to consider the specific requirements and regulations of the water treatment plant project when implementing steel props. Factors such as load capacity, corrosion resistance, and adherence to safety standards must be thoroughly assessed to guarantee the appropriate and safe utilization of steel props in water treatment plant construction.

Send your message to us

Vertical Structure Support System for Climbing Bracket CB240 & CB210

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches