Alu-slab

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1. Brief introduction

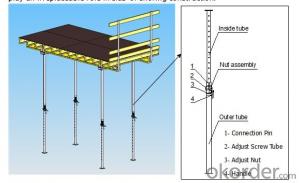

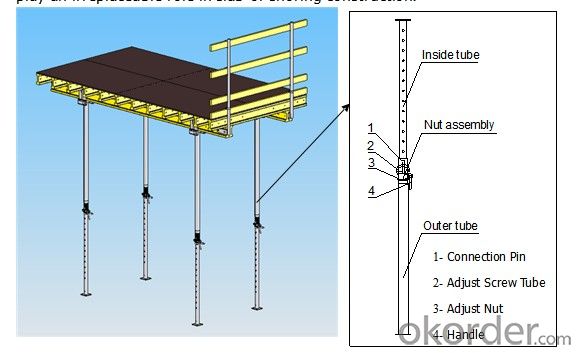

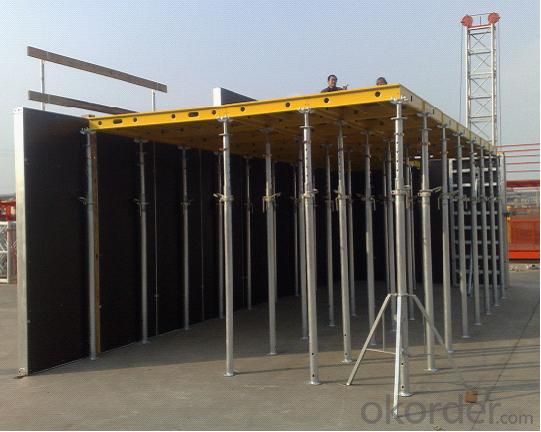

Especially for projects with a large number of similar applications and open facades, Alu-slab system is the right solution. The panel is end product, no assembling on site and it is easily to build, ease of application, more important thing is, the panel is light weight, a dead lift is achieved, save time and effort.

2. Competitive advantage

① Light weight but high load bearing capacity

The panels could be transported by manual work so that it greatly reduces the aggregate cost, accelerates the erection speed, and all in all increases the aggregate benefit.

②Quickly turnover of slab panels

The early dismantling prop system speed up the turnover of the panels, minimize the investment, lower the cost, improve the working efficiency, and shorten the project period under the precondition of keeping the concrete structure and safety uninfluenced, in line with the erection requirement and ensuring the project quality.

③Cost effective with early dismantling prop system.

This early dismantling system is simple, safe and fast, saving at least 50% percent of your construction time.

3. Applications

- Q: How is a steel prop different from other types of props?

- A steel prop is different from other types of props primarily in terms of material composition and structural strength. Unlike wooden or aluminum props, a steel prop is made entirely of steel, which provides it with superior durability and load-bearing capacity. One key advantage of a steel prop is its ability to withstand heavy loads and support structures with greater stability. Steel is renowned for its high tensile strength and rigidity, making it a suitable choice for propping up heavy beams, slabs, or other construction elements. Its robustness ensures that the prop remains stable and secure, even under significant pressure or weight. Another notable difference is the adjustability of a steel prop. Most steel props come with adjustable features, such as telescopic tubes or screw mechanisms, allowing users to increase or decrease their height as required. This adjustability is crucial in construction projects where different floor heights or uneven surfaces need to be accounted for. Wooden or aluminum props, on the other hand, often have fixed lengths, limiting their versatility in various scenarios. Furthermore, a steel prop can offer better fire resistance compared to wooden props. While wooden props are susceptible to burning, steel is non-combustible and can withstand high temperatures for longer periods. This fire-resistant property makes steel props a safer choice in construction sites where fire hazards are a concern. However, it's worth noting that steel props can be heavier and more cumbersome to handle than their wooden or aluminum counterparts. The additional weight may require more effort during transportation, setup, and dismantling. Additionally, steel props may be more expensive upfront compared to wooden props, although their long-term durability and reusability can offset this cost difference. In summary, a steel prop stands out from other types of props due to its robustness, load-bearing capacity, adjustability, and fire resistance. These features make steel props an ideal choice for construction projects that require reliable and versatile support for heavy structures.

- Q: Are steel props suitable for supporting temporary seating structures?

- Temporary seating structures can be effectively supported by steel props. These props, also known as adjustable steel props or acrow props, are widely used in construction and temporary structures to provide stability and support. Their adjustable height feature makes them versatile and adaptable for various applications, including supporting temporary seating structures. By virtue of their durable steel construction, steel props offer a robust and dependable support system. They are capable of bearing heavy loads and can be easily adjusted to the desired height, thereby facilitating flexibility when setting up temporary seating structures. Furthermore, steel props are highly practical for temporary structures due to their ease of installation and removal. They can be swiftly assembled and disassembled, saving time and effort during the setup and dismantling process. Moreover, steel props guarantee a high level of stability and safety. Equipped with sturdy base plates, they provide a solid foundation and prevent sinking into the ground. This ensures the seating structure remains stable and secure, even when accommodating a large number of people. Overall, steel props are a suitable and reliable choice for supporting temporary seating structures. Their strength, adjustability, ease of installation, and stability make them an ideal support system that can withstand heavy loads and ensure the safety and comfort of users.

- Q: Can steel props be used in the construction of dams?

- Yes, steel props can be used in the construction of dams. Steel props are often used as temporary supports during dam construction to provide stability and reinforcement to the structure. They are especially useful in areas where additional structural support is needed, such as during excavation and concrete pouring.

- Q: Can steel props be used for supporting temporary concert stages or platforms?

- Yes, steel props can be used for supporting temporary concert stages or platforms. Steel props, also known as adjustable props or acrow props, are commonly used in construction and temporary structures to provide support and stability. They are designed to bear heavy loads and can be easily adjusted to the desired height. When it comes to supporting temporary concert stages or platforms, steel props are an ideal choice. They can be positioned strategically underneath the stage or platform to distribute the weight evenly and ensure stability. Furthermore, their adjustable nature allows for precise leveling and customization to accommodate different stage heights or uneven ground surfaces. Steel props are made of high-quality steel and are designed to withstand significant loads, making them reliable and sturdy. They are also easy to install and dismantle, which is especially important for temporary structures like concert stages or platforms that need to be set up and taken down quickly. Overall, steel props provide the necessary support and stability required for temporary concert stages or platforms. They are a reliable and practical solution for ensuring the safety and durability of such structures.

- Q: What are the common maintenance tasks for steel props?

- To ensure the steel props are well-maintained, it is necessary to regularly clean and inspect them, lubricate the moving parts, and address any signs of damage or wear. To maintain the steel props in good condition, it is crucial to regularly clean them. This involves eliminating dirt, dust, and debris from the surface of the props. To accomplish this, a mild detergent or cleaning solution can be applied using a soft cloth or brush. It is important to avoid using abrasive materials or harsh chemicals that could harm the steel. Another essential maintenance task for steel props is inspection. This should be done regularly to detect any signs of damage or wear. Checking for rust, cracks, or bent parts is crucial to ensure the safety and functionality of the props. If any issues are found, the props should be repaired or replaced as necessary. Lubricating the moving parts of the steel props is also necessary. Hinges and joints may need to be lubricated to ensure smooth operation. The use of a suitable lubricant, such as oil or grease, will prevent friction and maintain the props' performance. Additionally, it is important to adhere to the manufacturer's guidelines for maintenance and care. These guidelines may include specific instructions for cleaning, lubrication, and storage. By following these guidelines, the lifespan of the steel props can be prolonged, and their safe and efficient use can be ensured.

- Q: What is the average lifespan of a steel prop?

- The average lifespan of a steel prop can vary depending on various factors such as its usage, maintenance, and the conditions it is exposed to. Generally, a well-maintained steel prop can last anywhere between 5 to 10 years. However, it is important to regularly inspect and maintain the props to ensure their longevity and safety.

- Q: Can steel props be used for temporary support during wall panel installation?

- Steel props are an ideal choice for temporary support when installing wall panels. Their adjustability allows for easy setting at the desired height, providing reliable support. With exceptional stability and strength, steel props can handle heavy loads during installation. Furthermore, their durability enables them to withstand the pressure exerted by wall panels, guaranteeing a secure and stable installation.

- Q: Can steel props be used for temporary support in bridge pier construction?

- Yes, steel props can be used for temporary support in bridge pier construction. Steel props are commonly used in construction projects to provide temporary support during the construction process. They are adjustable and can be easily installed to provide stability and reinforcement to bridge piers until the permanent supports are in place.

- Q: Can steel props be used in underground mining tunnel construction?

- Yes, steel props can be used in underground mining tunnel construction. Steel props are commonly used to support the roof and walls of tunnels, providing stability and ensuring the safety of workers. They are durable, strong, and can withstand the challenging conditions of underground mining operations.

- Q: Can steel props be used for supporting temporary roofs or canopies?

- Yes, steel props can be used for supporting temporary roofs or canopies. Steel props provide strong and stable support, making them well-suited for temporary structures that require additional stability and load-bearing capacity.

Send your message to us

Alu-slab

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords