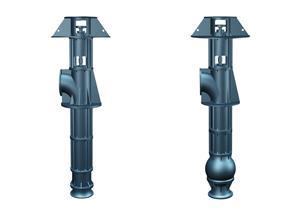

Vertical CANTILEVER pump HIGH EFFICIENCY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Design |

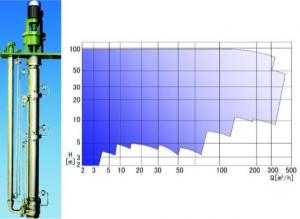

Overview of technical data

| Type of impeller | Open |

| Maximum drive rating | 184 kW |

| Impeller material (EN standard) | CA6NM; CF8M;JL 1040 |

| Type of bearing | Rolling element bearings |

| Drive frequency | 50 Hz / 60 Hz |

| Maximum speed of rotation | 3. 500 1/min |

| Maximum flow rate | 320 m³/h |

| Maximum discharge-side pressure | 10 bar |

| Top plate | Yes |

| Casing material (EN standard) | CA6NM; CF8M;JL1040 |

| Minimum flow rate | 0, 70 m³/h |

| Suction characteristics | Non- priming |

| Drive voltage | Low voltage |

| Pump set location | Dry installed, floodable |

| Max. permissible fluid temperature | 100 °C |

| Type of first impeller | Single entry |

| Main applications | Industry and process engineering; Water |

| Type of installation | Stationary |

| Type of casing | Volute casing |

| Type of lubrication | Grease / Oil lubrication |

| Type of drive | Electric motor |

| Installation position | Vertical |

| Shaft material (EN standard) | AISI- 316L;F-114 |

| Type of coupling | Direct |

| Shaft seal type | Shaft seal ring |

| Drive | Electric motor |

| Maximum head | 95, 00 m |

| Minimum head | 3, 50 m |

| Explosion protection | ATEX ( 94/9/EC) |

| Casing partition | Radially split |

| Maximum submergence | 1. 585 mm |

| Connection to power supply | 230/ 400 V, 3~ |

- Q: If the suction pump does not have enough suction range, you need to add a vacuum pump to increase the suction stroke. How do you install the suction pipe of the vacuum pump? Water pump impeller is not closed, it is normal that the vacuum pump is unable to pump suction pipe to a vacuum, is it because the water pump outlet pipe connected to the role of the check valve? But the water pump, outlet pipe, check valve sealing performance can achieve the function of non leakage?

- Vacuum suction principle of self suction pump:Assuming that the pump connected with the water inlet of a sealed container, the container has plenty of water, since the start of a water pump, water is thrown out of the water impeller pump body, water inlet seal vessel due to the extraction of water to form a vacuum cavity, this assumption will be connected to vacuum cavity and exposed to atmospheric conditions of water, water at atmospheric pressure under the effect of entry into the vacuum chamber".

- Q: What is cavitation, centrifugal pump cavitation phenomenon how to solve?

- The pump is in operation, if the over-current part of the local area (usually the impeller blade inlet somewhere later) for some reason, the absolute pressure of pumping the liquid was reduced to liquid vapor pressure temperature, liquid vaporization began in the area, produce a lot of steam, forming bubbles, when the liquid contains a lot of bubbles forward by high pressure impeller zone, high pressure liquid around the bubbles in the bubble decreases drastically and rupture. Condensation in the bubble burst at the same time, the liquid particle filled hole at a high speed, this moment has a very strong effect of water hammer, and with a high impact frequency against the metal surface, the impact stress of hundreds to thousands of atmospheric pressure, impact frequency can be up to tens of thousands of times per second, serious breakdown when the wall thickness will be.The process of cavitation in a pump is caused by the bursting of bubbles and bubbles in the water pump and the destruction of the over-current components. Water pump cavitation, in addition to the over-current components will have a destructive effect, but also noise and vibration, and lead to the performance of the pump down, seriously when the pump will be interrupted liquid, can not work properly.

- Q: Concrete pump 125 pipe wall thickness

- Currently mainly divided into gate valve, concrete pump and S valve concrete pump. Another is a pump consisting of a pump body mounted on an automobile chassis and fitted with retractable or bent cloth poles

- Q: How to distinguish the flow and displacement in the hydraulic pump? What's the difference between the two?

- For example, once you sprinkle water from the tank to the ground, one shot of water is 1000 milliliters, which is equivalent to displacement, once (pump turn) 1000 ml.,

- Q: What is a positive displacement pump? He Weizheng displacement?

- The principle and structure of positive displacement pumps are similar to those of hydraulic motors. Positive displacement is the pump outward to provide flow and pressure, that is, conventional pumps. A negative displacement pump is a hydraulic motor that rotates by external pressure and flow.

- Q: Water pump does not produce water, what are the reasons?

- 1 check whether the motor is reversed.2, to see whether the export, the entrance blocked, the outlet pressure gauge whether there is pressure.3, whether the pump selection is wrong, you can not suck up the water.

- Q: What should be used to pay attention to the use of mechanical pumps?

- Overall: large pump should first do a good job of the foundation, to find a good whole, fixed, and motor, pump should be added good oil, the first test of the motor, and then conjoined test

- Q: Which nuclear submarines use the shaftless pump technology?

- The team led by academician Ma Weiming of China is now carrying out the research on this technology and has achieved initial success.. This technology is expected to be applied to the next generation of domestic submarines.

- Q: When the water pump is started, why should it start when the outlet valve is closed? Thank you

- When the valve is closed, the flow of the pump is close to zero, the power of the pump is very small, which reduces the load that the motor starts to bear and has a protective effect on the motor. Therefore, the valve closed to start the pump.

- Q: Filter backwash pump for what use, what is the principle of work ah?

- Regeneration of the filter medium is required to regain the filtration capacity of the medium. The regeneration process is mainly accomplished by the backwashing pump (the backwash pump is not a special pump, referring to the pump for the completion of the process). The working principle is through the cleaning liquid from the downstream of the filter into the backwash pump (alkali, acid and water), reverse flushing filter medium, cleaning liquid discharged from the upstream, this process can be attached to the dielectric surface and internal impurities washed away.

Send your message to us

Vertical CANTILEVER pump HIGH EFFICIENCY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords