VD/VOD Vacuum Ladle Refining Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

VD/VOD Vacuum Ladle Refining Furnace

40TVOD furnace

100T VD furnace

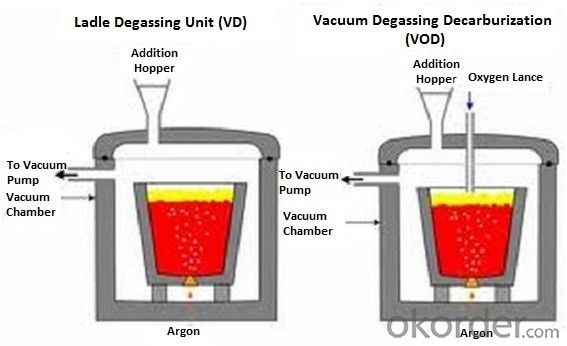

In recent years, secondary vacuum refining technique gets popular and further developed. The heart of global metallurgical industry has transferred from quantitative to be variety diversification and high quality. The super purity index ( total [H]、[N]、[O]、[S]、[P] get 50ppm,or even lower) reflects the quality of product, The effective way to achieve super purity index is secondary vacuum refining technique. There are many ways of secondary vacuum refining, the most popular ways are:1, VD- ladle vacuum refining process.2, VOD- vacuum oxygen decarburization ladle vacuum refining process.

VD/VOD ladle vacuum refining process strengthens blowing argon reasonably on the bottom of furnace; it can stir molten steel adequately and get ideal dynamics effect. If combining VD and LF, the furnace can get ideal molten steel refining temperature with easy structure and low cost. Both of the above process can dehydrogenize, denitrify, desulfurize, deoxidize under vacuum conditions and get the function of Vacuum Oxygen Decarburization (VOD) to achieve the purpose of refining super pure steel.

Vacuum pump system is the main equipment of vacuum refining device. Base on our ten years experience of test research and generalized application, two series products – “Full steam jet vacuum pump system” and “Steam jet + water ring vacuum pump system” had formed. “Full steam jet vacuum pump series” uses a certain pressure water steam and cooling water as working medium of the pump, “Steam jet +water ring vacuum pump system” uses a certain steam pressure, less water steam and cooling water as working medium, and consume few electricity. The steam consumption of “Full steam jet vacuum pump” is relative high, and need to equip with bigger boiler, but the cost of vacuum pump itself is lower. The steam consumption of “Steam jet +water ring vacuum pump system” is relative low, and can equip with a smaller boiler, but the vacuum equipment itself costs higher. So the total investment cost of above system is basically consistent, both are satisfied the requirement of producing molten steel by secondary vacuum refining.

Our company is a Key enterprise and professional manufacturer of steam jet vacuum pump and whole vacuum equipments in China, and we are also the first corporation of designing and producing VD/VOD Vacuum refining equipment and VC Vacuum Cast Equipment in China. Up to now, we had designed and produced more than 180 sets VD/VOD, RH vacuum refining equipment, VC vacuum casting equipment for more than 100 companies. All these equipments meet the requirements of design and well received by the end user.

- Q: What is the difference between industrial furnaces and boilers?

- Hot water or steam generated in the boiler can directly provide necessary energy for industrial production and people's life, but also by the steam power device is converted to mechanical energy, or through the generator converts mechanical energy into electrical energy. Hot water boilers are called hot water boilers. They are mainly used in daily life, and are also used in industrial production. Steam generating boilers are called steam boilers, often referred to as boilers. They are used in thermal power stations, ships, locomotives and industrial and mining enterprises.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- Heat treatment furnace is mainly for the mechanical processing and casting industry workpiece annealing, quenching, carburizing, quenching and tempering, heat treatment equipment.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- There are many kinds of furnaces in metallurgical industry,colored and black,smelting and heat treatment are also included.

- Q: What are the combustion equipments used in industrial boilers?

- The boiler is an energy conversion equipment. The energy input to the boiler has the chemical energy and the electric energy in the fuel. The boiler outputs steam with certain heat energy and high temperature water.

- Q: What's the role of anchor bricks in industrial furnaces?

- These layers need to be joined and anchored. Anchor brick is this role. The heat insulation layer at the horizontal section of the flue is mostly a narrow cavity.

- Q: Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q: What are the advantages of a vacuum furnace?

- No pollution to the environment, no need for three wastes treatment.

- Q: How to use industrial furnace equipment?

- When the furnace is used, the lifting mechanism of the furnace door must be in good condition, and the wire breakage of the steel wire is not allowed to exceed the designated value. The weight should be properly allocated, and the drive department shall be provided with a protective cover.

- Q: Brief introduction to repair of industrial furnace

- The industrial furnace is the main production equipment in the machinery industry. The repair of industrial furnace directly affects the quality, high yield, long life, low consumption and safe production of the furnace.

- Q: What is the difference in structure between industrial furnace and boiler?

- From the way: industrial furnace (electricity, natural gas, gas, induction heating is considered electricity), boilers (coal, all kinds of hot exhaust gas, a variety of gas, seemingly less electricity).

Send your message to us

VD/VOD Vacuum Ladle Refining Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches