Disposable Aluminum Baking Sheets - Various Thickness Different Size Aluminium Coil 3105 H16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

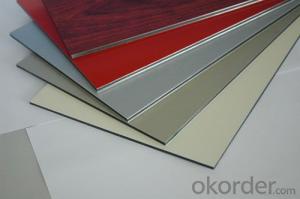

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

1100-H14-DIAMOND EMBOSSED ALUMINUM SHEET

Thickness:1.2mm---4mm,

width:1000mm---1500mm

Product code: 618 a - 33 y titanium matte aluminum plate

Technical parameters

Aluminum alloy/material: 1100

Tensile strength N/was: 115-125

The yield strength of N/was: 150-150

Elongation % : 3 or more

Rainbow degrees: no

Process: light oxidation process

Product description: surface "colored metal silken face" as the main characteristics of the product, completely metal texture, color variety, products can be mild tensile and bending.

Product use: can be used to directly shape stamping, screen printing, thermal transfer two composite process, etc.Used in architectural decoration, household appliances, switch panel, auto parts, lamps lighting, electronic hardware and other industries.

Supply scope of coil or sheet

Mm thickness specification: 0.4 1

Maximum width mm: 1250

The tolerance range

Mm thickness: 0.02 mm

The width of the mm: 2 -

Mm length: 2 -

Actual weight kg: plus or minus 2

Protective film

Protective film on the surface of the aluminum quality assurance period for six months, aluminum is kept dry and ventilated, avoid heat and direct sunlight.If the aluminium material stored in high temperature or direct sunlight can cause protective film, or unable to tear in addition to wait for a phenomenon.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

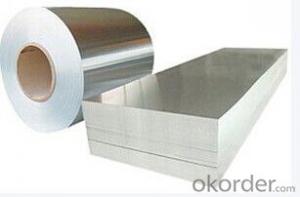

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: How do you prevent galvanic corrosion when using aluminum sheets with saltwater?

- To avoid galvanic corrosion when utilizing aluminum sheets in saltwater, there exist several steps that can be taken: 1. The application of protective coatings is one effective method. This can be accomplished by employing specialized marine-grade paints or coatings specifically designed to hinder corrosion in saltwater environments. These coatings act as a barrier between the aluminum and the saltwater, effectively reducing the probability of galvanic corrosion. 2. Another approach involves the utilization of isolation materials, such as rubber or plastic gaskets, between the aluminum sheets and any dissimilar metals that may come into contact with them. These materials prevent direct contact between the aluminum and other metals, thereby minimizing the risk of galvanic corrosion. 3. Galvanic corrosion inhibitors can be added to the saltwater to help mitigate the risk of corrosion. These inhibitors function by creating a protective layer on the aluminum surface, thereby preventing the electrochemical reactions that lead to galvanic corrosion. 4. The implementation of cathodic protection techniques can also assist in preventing galvanic corrosion. This entails connecting the aluminum sheets to a sacrificial anode made from a more active metal, such as zinc or magnesium. The sacrificial anode corrodes instead of the aluminum, thus safeguarding it from galvanic corrosion. 5. Proper maintenance is crucial in preventing galvanic corrosion. Regularly cleaning and maintaining the aluminum sheets is essential, as saltwater and other contaminants can accumulate on the surface, promoting corrosion. Cleaning the sheets with fresh water and eliminating any salt deposits can help prolong their lifespan and reduce the risk of galvanic corrosion. It should be noted that these preventive measures should be implemented alongside proper material selection and design considerations. Seeking guidance from corrosion experts or engineers specializing in marine applications can provide further insight into the specific requirements and best practices for preventing galvanic corrosion when using aluminum sheets in saltwater.

- Q: This question asks for a comparison of the positive and negative aspects of utilizing aluminum sheets in various applications.

- <p>Advantages of using aluminum sheets include their lightweight nature, which reduces transportation and handling costs. They are also corrosion-resistant, making them suitable for outdoor applications. Aluminum sheets are recyclable and environmentally friendly, with a high recycled content rate. They are also easy to fabricate and can be cut, bent, and shaped into various forms. Disadvantages include lower strength compared to steel, which may require thicker sheets for certain applications. They can also be more expensive than some other materials, and their light reflection can sometimes be a concern in certain environments.</p>

- Q: How would you write the formula for aluminum sulfate and calcium chloride?

- Aluminium sulfate: Molecular formula Al2(SO4)3·16H2O Calcium chloride: Molecular formula CaCl2

- Q: What are the different alloy compositions available for aluminum sheets?

- There are several alloy compositions available for aluminum sheets, each with its own unique properties and applications. Some common alloy compositions include: 1. 1100: This alloy is known for its excellent corrosion resistance and high thermal conductivity. It is often used in chemical equipment, heat exchangers, and food processing equipment. 2. 3003: This alloy has good formability, moderate strength, and excellent corrosion resistance. It is commonly used in packaging, tanks, and architectural applications. 3. 5052: This alloy is known for its high strength and good formability. It is often used in marine applications, as well as in aircraft and automotive parts. 4. 6061: This alloy has excellent strength, good formability, and high corrosion resistance. It is commonly used in structural applications, such as in bridges, buildings, and transportation equipment. 5. 7075: This alloy is known for its extremely high strength and good machinability. It is often used in aerospace applications, as well as in high-stress parts for the automotive and sporting goods industries. These are just a few examples of the many alloy compositions available for aluminum sheets. The choice of alloy will depend on the specific requirements of the application, such as strength, corrosion resistance, formability, and machinability.

- Q: Are the aluminum sheets suitable for manufacturing transportation containers?

- Yes, aluminum sheets are suitable for manufacturing transportation containers. Aluminum is a widely used material in the transportation industry due to its excellent properties. It is lightweight, yet strong and durable, making it ideal for containers that need to be transported over long distances. Aluminum sheets also have good corrosion resistance, which is crucial for containers that may be exposed to different weather conditions during transportation. Additionally, aluminum is easily recyclable, making it an environmentally friendly choice for manufacturing transportation containers. Overall, aluminum sheets provide the necessary strength, durability, and corrosion resistance required for manufacturing transportation containers.

- Q: This question asks for methods to clean aluminum sheets to preserve their appearance.

- <p>To clean aluminum sheets and maintain their appearance, follow these steps: 1. Use a mild detergent mixed with warm water to create a cleaning solution. 2. Gently scrub the aluminum sheets with a soft cloth or sponge to avoid scratching the surface. 3. Rinse thoroughly with clean water to remove any detergent residue. 4. Dry the sheets immediately with a soft, dry cloth to prevent water spots. 5. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. 6. Avoid using harsh chemicals or abrasive materials that can damage the aluminum's finish. Regular cleaning will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: What are the potential safety issues that may arise from the use of aluminum sheets?

- <p>Aluminum sheets are generally safe to use in most applications. However, there are a few safety concerns to consider. First, aluminum can be a skin irritant for some individuals, so it's important to wear protective gloves when handling. Second, aluminum dust, when inhaled, can cause respiratory issues. Proper ventilation should be maintained during cutting or grinding operations. Lastly, aluminum can conduct electricity, so it should not be used in electrical applications without proper insulation. Always follow safety guidelines and use protective equipment when working with aluminum sheets to minimize these risks.</p>

- Q: What are the common thicknesses of aluminum sheets used in aerospace applications?

- The common thicknesses of aluminum sheets used in aerospace applications range from 0.5 mm to 6 mm, depending on the specific requirements and structural needs of the aircraft or spacecraft.

- Q: What are the different grades of aluminum sheet?

- There are several different grades of aluminum sheet available in the market, each with its own unique properties and applications. Some common grades include: 1. 1100: This grade is known for its excellent corrosion resistance and high thermal conductivity. It is often used in chemical equipment, reflectors, heat exchangers, and electrical conductors. 2. 3003: This grade is alloyed with manganese, making it highly resistant to corrosion. It is commonly used in cooking utensils, storage tanks, and architectural trim. 3. 5052: This grade has good formability and high fatigue strength. It is often used in marine applications, such as boat hulls and components, as well as in aircraft fuel tanks and structural parts. 4. 6061: This grade is known for its excellent strength-to-weight ratio and good machinability. It is commonly used in automotive parts, bicycle frames, and structural components. 5. 7075: This grade has high strength and toughness, making it suitable for aerospace applications, such as aircraft wings and fuselage structures. Each grade of aluminum sheet has its own specific characteristics and is chosen based on the requirements of the particular application. It is important to consider factors such as corrosion resistance, strength, formability, and machinability when selecting the appropriate grade.

- Q: What rules or guidelines exist for using recycled aluminum sheets in construction projects?

- <p>Yes, there are regulations and guidelines regarding the use of recycled aluminum sheets in construction. These often include standards for material quality, safety, and environmental impact. The American Society for Testing and Materials (ASTM) and the Aluminum Association provide specifications for recycled aluminum alloys used in construction. Compliance with building codes and local regulations is essential. Additionally, recycled aluminum must meet performance and safety standards equivalent to those of new materials. It's crucial to check with local building authorities and consult the latest industry standards to ensure compliance when using recycled aluminum in construction.</p>

Send your message to us

Disposable Aluminum Baking Sheets - Various Thickness Different Size Aluminium Coil 3105 H16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords