Vapor Barrier Membrane with Aluminum Foil Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vapor Barrier Membrane with Aluminum Foil Coated

Introduction:

Vapor insulation membrane is a roof membrane with three-layers, which is specially designed for application on ventilated pitched roofing, can be used under bituminous membrane as a extra protection for the attic insulation. It includes PET/PP non-woven fabric layer, PE/PP woven layer and aluminum foil layer. The three-layers structure ensure extreme resistance to tearing. Furthermore, the special stabilization additives ensure 3-month resistance to UV radiation.

Specification:

Chemical Composition | PP & PE, Aluminum Foil, Woven Fabric |

Roll Size | 1.5meter*50meter |

Density: | 60gsm~130gsm |

Tensile Strength | MD:150N/50mm; CMD:115N/50mm |

Waterproofing Rate | W1 |

Vapor Resistant Rate | 6.9g/m2 ▪ 24h |

Aging rate under hot circumstance (90℃*168h) | MD:90%; CMD:100% |

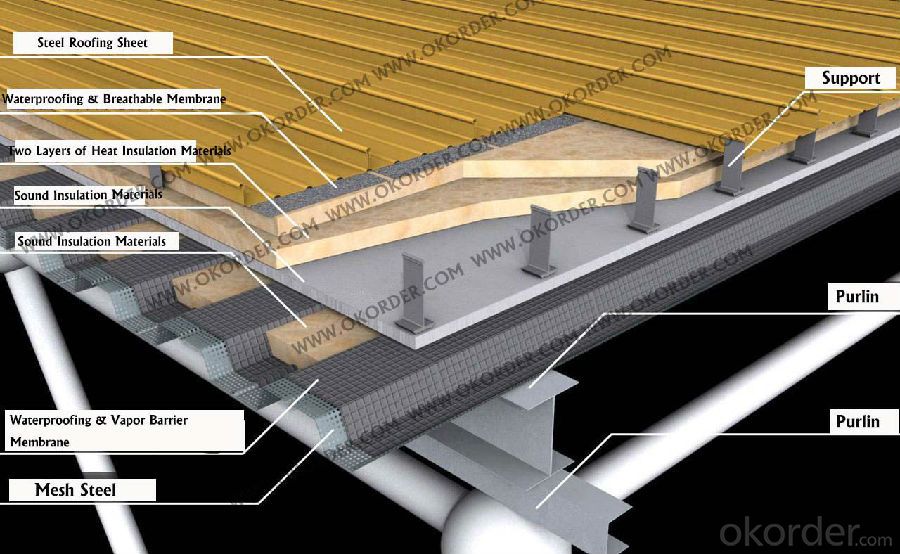

Typical Installation

Typical Application:

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu province, close to Shanghai.

2. Have you ever been export?

Yes, our product has been exported to many countries.

3. Can we get samples?

Yes, we are free for samples, what you need to assume is freight charge.

- Q: Bathroom first leveling or do waterproof, what is the difference

- 7. The threshold stone is only decorated, do not mistakenly believe that can hold water. In short, each process have to carefully do not leave a hidden trouble to ensure worry. But the reality of the structure, materials, workers, mutual protection and many other unsatisfactory, so that waterproof is a common problem, perhaps set (overall) bathroom by the factory as a whole production test, on-site assembly will solve this common problem.

- Q: Slope roof drains do not need to be waterproof

- The overall rigid waterproof layer is often due to these small structural nodes handled properly, resulting in the failure of the entire roof waterproof.

- Q: Find the construction steps for waterproof coatings

- 2, waterproof layer construction sequence and methods (1) base surface treatment and acceptance of qualified, and now Yin, Yang angle and construction joints and other special parts brushing waterproof coating layer, strengthen the layer 1 mm, strengthen the layer after brushing, immediately paste fiberglass cloth or 30 ~ 40g / ㎡ polyester cloth reinforcement layer, is strictly prohibited to strengthen the surface layer and then paste the reinforcement layer material. (2) to strengthen the layer of hard work, began to brush a large waterproof layer, waterproof layer using multi-channel (3 to 5) brushing, brushing the upper and lower coating should be perpendicular to each other. When the surface of the coating is completely cured (not sticky hands) before the next curtain coating construction. (3) polyurethane coating waterproofing layer after the completion of the experience of acceptance, the timely application of the waterproof layer of the protective layer, the plane protective layer with 7 cm thick fine stone ㎝, in the pouring of fine stone before the need to cover the waterproof layer A layer of 350 # paper tire linoleum insulation layer. Facade waterproof layer (such as anti-beam facade) with a thick 6 mm polyethylene foam protection (expansion ratio of not more than 25 times).

- Q: What material is used for waterproofing of tarpaulin

- Regardless of the construction or finished products are toxic, due to organic materials, it will form a separation layer, partition structure of poor wear resistance, must be a protective layer of solid, not hollowing, but requires the base surface moisture content of less than 8% overlap requirements No interface to form a seamless body thickness control easy to control the local thickness difficult to control

- Q: What material waterproofing can be mixed with cement sand

- Construction can also be used to produce waterproof pulp, waterproofing agent for the amount of cement 3 ‰ -4 ‰, the use of cement label not less than 32.5MPa.

- Q: FRP finished brush on what can be waterproof do not fade

- On the surface of the gel coat it is, a lot of gel coat points, the specific performance of what you want, you can communicate with the supplier

- Q: What should you pay attention to before the construction of the basement waterproofing membrane?

- 3, painting the bottom line: for the reasonable arrangement of the daily pavement workload, must first on the basis of the program according to set the program to draw a good dividing line, the entire track and field into pieces, and then press the block by pavement. In order to ensure smooth drainage and less joints and other requirements, the use of the first outer ring after the construction process.

- Q: Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- First, rigid (concrete) waterproof roofing SBS membrane should not be painted before the coating of any waterproof coating, otherwise it will damage the bonding strength of the coil and the grassroots.

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material 4: sauna board ????This is a dedicated wood panel for the sauna, but it can also be used in the kitchen and bathroom, generally degreased, with high temperature, not easy to deformation, health and environmental protection and other characteristics, even if there is a long time in the water Will not rot, usually painted in a layer of paint decoration, can make the overall ceiling more beautiful.

- Q: Finished house bathroom waterproof household acceptance should be how to accept?

- 3: waterproof cement mortar leveling layer and foundation with dense, no hollowing, smooth surface, no cracks, from the sand, yin and yang angle made of circular arc.

Send your message to us

Vapor Barrier Membrane with Aluminum Foil Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords