UPVC Pipe And CPVC Solid Pipe Plastic Extruder Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Our pipe extrusion line can be used to produce PVC, HDPE, and HDPP pipes with the diameter between 12mm and 400mm. The well-coordinated components, coupled with auxiliary machines, allow this pipe production line to produce pipes for different purposes, including drain pipes, water supply pipes, electrical conduits, PVC fire-retardant pipes, as well as piping for use in chemical industry.

Working flow:

Mixer→ Vacuum feeding →Material dry → Single screw extruder →Marking line extruder(co-extrusion)→Vacuum calibration spraying cooling tank → Spraying cooling tank→ Color-ribbon printer → Haul-off machine →Cutter →Stacker

Packaging & Delivery

| Packaging Detail: | plastic film package or according to customers' demand |

| Delivery Detail: | 30 days after receiving 30% advanced payment |

Specifications

1.Easy to operation and running steadily

2.Good after-service

3.Preferential price

4.Advanced Design

Main charaters:

This line can solve the problems of high temperature melting, high viscosity, easy-decomposition. The

special designed screw, gearbox, tooling, and HMI system make the line reliable and easy operation.

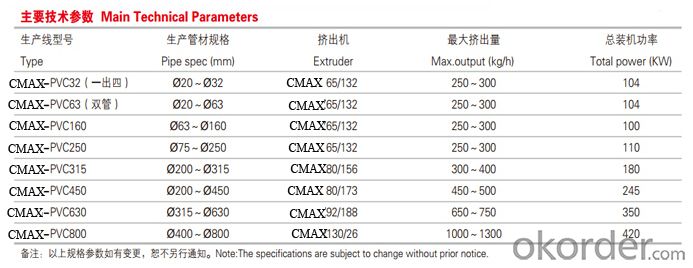

Main Technical Parameters

If you are interested in our product, please be free to contact us.Whether we could cooperate, we would do our best to help you. I’m confident that will be benefit to you and us!

FAQ:

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the diameter of pipe(inch or mm); thickness of pipe wall(mm); width and thickness of sheet (mm)? If profile product, you’d better offer the picture of sample or drawing of sample.

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

- Q: when I use armature voltage feedback (host start speed 50, normal can produce 10It is normal to start at 80 or 150 of the speed, but after a few minutes the motor does not turn. 590 alarm (missing pulse alarm). When I change the feedback mode to speed feedback, my host sometimes starts and sometimes fails to start. I hope you help me, how should I adjust?. Thank you。

- I've also encountered (missing a pulse alarm), and finally checked out is a SCR triggered, impassability, you can try

- Q: Basic parameters of extruder screw

- 1, screw diameter Ds screw diameter is the diameter of the thread, the extruder production capacity (extrusion amount) is approximately proportional to the square of the diameter of the screw and, under the same other conditions, the screw diameter increases a little, significant increase will cause extrusion amount, the effect was even greater than the effect of the increase of screw speed on the extrusion rate is high. Therefore, the screw diameter is used to characterize the specifications of the extruder.

- Q: What impact does the extruder vacuum pump open or close on the extrusion product?

- If the vacuum pump does not open, it may cause bubbles in the extruded product.

- Q: What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q: What are the common extrusion molding products?

- Extrusion molding products are as follows:1 、 plastic pipe, for example: water pipe up and down;2, plastic profiles, such as: doors and windows, plastic steel profiles.3, plastic plates, such as: wood plastic doors, plastic doors,4, plastic sheet (sheet and board is the difference between the thickness, thin, thick plate), such as: mobile phone membrane.

- Q: What raw material does the extruder use?

- The utility model has the function that the plastic melt from the extruder barrel is well distributed in the die runner so as to be extruded and formed from the die at a uniform speed. The forming action of an extrusion die is in the process of complete extrusion (see plastics processing). A plastic extruder consists of an extrusion system, a drive system and a heating and cooling system. The classification system of extrusion system includes 1. extrusion screw, barrel, hopper, head, and mould, plastic extrusion system by plasticizing evenly into the melt, the establishment of Liu Hesheng basic information name in this process and Liu Hesheng taught: - professional engineering

- Q: Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q: Extrusion machine operating procedures, specific points, thank you!

- 6, the speed from low to high, added to the normal speed, is strictly prohibited high-speed car, observe the instrument on the current value and temperature is normal, in case the current is too large, cause the heater to burn.7, when lifting the disk, we should pay attention to the limit of the rise and fall, not too high or too low, when there is an electrical limit, shall not exceed the limit.8 when feeding to the hopper, be careful not to enter the metal, and do not use a screwdriver or a metal bar to poke the plastic into the screw.9 check the dry test machine, should be equipped with rubber insulation plate, otherwise, no driving.10 before driving, should check whether the ground location is good, grounding resistance should be measured regularly, not higher than 4 Europe; equipment whether there is noise and other anomalies, if there is a problem, repair and reuse.

- Q: Now I want to do it How to change the equipment, please help tell your heroes ah!Used to do PVC pinch plate, now changed to PVC threading tube

- Do the plate equipment and pipe threading with PVC equipment, from the process, are PVC extrusion machinery, however, do different products, screw inside or something different, if you want to do product grade requirements is not high, can change, but stability is not so good ensure product.

- Q: Who knows the temperature regulation method of the extruder?Any information will do

- 1, extrusion methodAccording to plasticizing methods: dry extrusion and wet extrusionPress the way: continuous extrusion and intermittent extrusion2, characteristicsContinuous production, high efficiency, simple operation, wide range of applications [Edit] paragraph extrusion molding equipment 1, the hostExtrusion system: composed of screw and barrel, it is the key part of extruder. Its function is to melt plastics, quantitative, constant pressure, constant temperature extrusion of meltDrive system: drive the screw to increase the required torque and torqueHeating and cooling system: guarantee the temperature of plastic and extrusion system in molding process2 auxiliariesIt is composed of head, setting device, cooling device, traction device, coiling device and cutting3 、 control systemIt consists of electric apparatus, instrument and actuating mechanismPurpose: to control the main and auxiliary motor, in order to meet the demands of speed and power; control main engine temperature and pressure and flow, to ensure product quality; to achieve automatic control of the extrusion unit, ensure the coordinated operation of main and auxiliary equipment. [edit this paragraph] extruder extruder overview of plastic extruder is the host, it consists of extrusion system, transmission system and the heating and cooling system.

Send your message to us

UPVC Pipe And CPVC Solid Pipe Plastic Extruder Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords