Plastic extruder/Plastic pvc pipe production line/PVC Pipe Extrusion Line/PVC pipe making machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction

Extruder/Screw And Barrel for Extruder/Plastic Extrusion

Screw Diameter 55 to 65mm

30 to 100 KG/HR

AC20 to 40HP/11.5 to 15KW

Reference Values

| CMAX series twin-screw extruder | |

| Mixing modification | PE,PP,PS+SBS,PA+EPDM,PP+NBR,NVA+silicon rubber,etc |

| PE,PA,PC,CPE+ABS(ALLOY),ABS+TPU,PBT+PET,PE+PP,etc | |

| Filling modification | PE,PP,EVA,etc+Calcium carbonate,talcum power,titanic powder, |

| ABS,PC,PS,etc+aluminum hydroxide,magnesium hydroxide,antimony oxide | |

| PP,PA,ABS+ferrous powder,sulphuric powder,ceramic powder | |

| Functional masterbatch | PP,PA,ABS,PBT,etc+burning agent and other auxiliary agents: combustion-supporting machine pellets |

| PP,PE,PS etc+starch:de-composing machine pellets | |

PE+fog-preventing dipper,stabilizer: dual-prevention machine pellets | |

| PE,EVA,ABS+carbon black:black machine pellets | |

| Colored masterbatch | PE,PP,ABS,AS,PA,EVA,PET+pigment and auxiliary |

| glass fibers/ carbon fibers reinforcement | PP,PBT,ABS,AS,PA,PC,POM,PPS,PET,etc+long fibers, small fibers,carbon fibers,crystals and so on |

| Various cables | HDPE,LDPF,LLDPE,MDPE,EVA,PVCetc+Insulating cables, coatings,PE peroxide,silicon alkyl crossing cables |

| Special materials | EVA heat-melting glue,polyurethane,fluorin rubber,fluorin plastics, PP cigarette filtering material and TPR sole material |

| Reaction extruding | Polyamide condensate,polyamide melting polymerization, polyamide polyethrne-adding,polycarbonate condensate,etc |

| Exhausting and Volatilization | Polystyrene oxide,high-absorbing resin,chlorine sulphur polyethylene |

| Powder paint | Polyester,ring oxide,lactide,polyurethane,acrylate |

Security Protection

1.coupling can effectively protect the reduction gearbox from extrusion unit overload dangers.

2.water-cooling system and lubrication systems are all real-time online monitoring.

3.drive ead pressure and melt temperature are all equipped with alarm systems.

Application

PVC pipe is mainly used in the agricultural water supply and drainage, water supply and drainage construction, cable supporting, thickness of pvc plastic pipe, The lines have conical twin-screw extruder, vacuum calibration tank, haul-off machine, cutting machine, stacker or belling machine and so on. Haul-off machine have two caterpillar, three caterpillar, and four caterpillar, six caterpillar, the cutter use knife-raised cutter or planetary cutter which support chamferring function. And the stacker take into account length, production line is reliable performance, and high quality, we have exported to Egypt, Brazil, Syria, Uzbekistan etc.

Characteristic

Pipe range | 20-63mm single | 20-63mm dual | 75-160mm | 110-315mm | 315-630mm |

Extruder | SJZ51/105 | SJZ65/132 | SJZ80/156 | SJZ80/156 | SJZ92/188 |

Extruder power | 18.5kw | 37kw | 37kw | 55kw | 110kw |

Extrusion capacity | 120kg/h | 250kg/h | 250kg/h | 360kg/h | 800kg/h |

Max. Production speed | 12m/min | 10m/min | 6 m/min | 3 m/min | 1.2m/min |

1) Main machine uses PVC twin screw, and notch feeder with powerful water

cover cooler, which has greatly improved transmitting capability and ensured

extruding.

2) Adopting double pipe extrusion method, it can greatly increase productivity.

3) Adopting high efficiency double-cavity vacuum calibrating technology and spray-paint

cooler gullet, which improve the finished product passing rate, and meet

the requirements of high speed manufacturing. Vacuum calibrating platform and cooler

gullet are all made of stainless steel

4) Adopting multi-caterpillar haul-off, through the central motor to run all the caterpillar

to reach same height, and ensure roundness of pipes

5) Adopting fully automatic control system with high precision, reliable operation,

easy and convenient handling

6) Suitable pipe diameter: 20 - 630mm

Process flow

PVC powder + additive --- mixing---feeder---twin screw extruder---mould and calibrator---vacuum forming machine---haul-off machine---cutting machine---discharge rack(or belling machine)

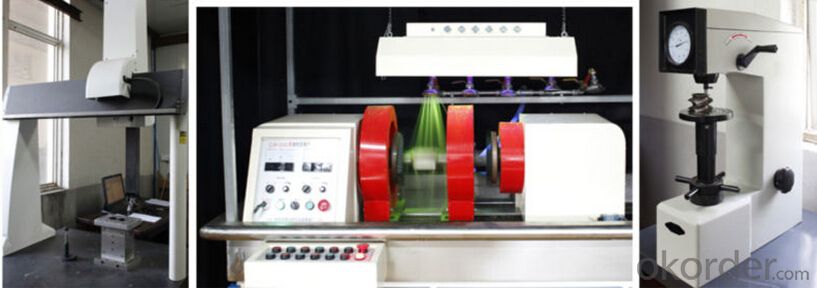

Product show

Our machine types:

1. Co-Rotating Parallel Twin Screw Pelletizing Extruders

2. Single Screw Pelletizing Extruders

3. Die Face Cut (Air Cooling) Pelletizing Extruders

4. Double Stage / Double Degassing Recycling Extruders

5. Crushers, Mixers, Storage Tanks, Vibrators, Granulators, Blowers

6. Extruder spare parts

FAQ

PVC sheet extrusion

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: For example, 70 square conductors, the outer diameter is A, out of the insulation, then the line mouth to choose how much, how much plastic cover election? Then the sheath, then how to choose the mold?

- PVC1.6 DYWL material with smaller good-looking it is simple of the extrusion process

- Q: What is an extruder?

- Coextrusion is divided into two color co extrusion and hard and soft coextrusion.

- Q: Wire and cable extrusion machine temperature exceeds the process documentation, what are the reasons?

- When making documents, they are not in accordance with the actual situation.

- Q: Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- Adjust the assembly and check the exhaust block

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- 1. injection molding2., the structure is relatively complex, high appearance requirements. Extrusion does not meet requirements3. most are: ABS, ABS+PC, PP and so on4., according to color requirements granulation - drying particles - filling the mold ---- debugging injection molding machine ---- injection molding production - after the selection of finished packaging (if silk screen requirements, but also the need for silk screen)

- Q: What should be paid attention to in the daily maintenance of the extruder?

- Extrusion machine regular maintenance mainly has these aspectsdrive system(1) check the temperature rise of motor and oil tank, whether the bearing is overheated locally, the abnormal noise of motor and gear, oil leakage, radial circle of oil filter and spline shaft, and the contact gap with the end of screw.(2) regularly clean the oil filter and remove the dirt at the bottom of the tank, and lubricate the lubrication points regularly.(3) the new gear box has been filled with gear oil, and new oil will be replaced every 4000 hours after the operation.

- Q: The working principle of an extruder

- What is the working principle of an extruder?:Screw with specific shape,Turn in a heated barrel,It will be delivered from the hopperThe plastic is pressed forward, allowing the plastics to be uniformly plasticized (i.e., melted)Through the head and different shapes of the mold, the plastic extrusionA continuous plastic layer of various shapes, extruded on the core and cable.

- Q: Now I want to do it How to change the equipment, please help tell your heroes ah!Used to do PVC pinch plate, now changed to PVC threading tube

- If you want to change, it is best to find the original purchase of equipment manufacturers, so that they change for you.

- Q: Who knows the temperature regulation method of the extruder?Any information will do

- 1, extrusion methodAccording to plasticizing methods: dry extrusion and wet extrusionPress the way: continuous extrusion and intermittent extrusion2, characteristicsContinuous production, high efficiency, simple operation, wide range of applications [Edit] paragraph extrusion molding equipment 1, the hostExtrusion system: composed of screw and barrel, it is the key part of extruder. Its function is to melt plastics, quantitative, constant pressure, constant temperature extrusion of meltDrive system: drive the screw to increase the required torque and torqueHeating and cooling system: guarantee the temperature of plastic and extrusion system in molding process2 auxiliariesIt is composed of head, setting device, cooling device, traction device, coiling device and cutting3 、 control systemIt consists of electric apparatus, instrument and actuating mechanismPurpose: to control the main and auxiliary motor, in order to meet the demands of speed and power; control main engine temperature and pressure and flow, to ensure product quality; to achieve automatic control of the extrusion unit, ensure the coordinated operation of main and auxiliary equipment. [edit this paragraph] extruder extruder overview of plastic extruder is the host, it consists of extrusion system, transmission system and the heating and cooling system.

Send your message to us

Plastic extruder/Plastic pvc pipe production line/PVC Pipe Extrusion Line/PVC pipe making machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords