PVC Pipe Line Plastic Pipe Extrusion With CMAX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction

This PVC pipe production line is mainly used in the agricultural water supply and drainage, water supply and drainage construction, cable supporting, thickness of pvc plastic pipe, The PVC pipe production line has conical twin-screw extruder, vacuum sizing box, traction machine, cutting machine, stacker frame and so on, Extruder, vacuum shaped tank, and haul-off machine motor produce high-quality products, haul-off machine have two-claw, three claw, and four claw, six claw, the cutter use knife-raised cutter or planetary cutter. And the stacker take into account length.

Characteristic

Pipe range | 20-63mm single | 20-63mm dual | 75-160mm | 110-315mm | 315-630mm |

Extruder | CMAX51/105 | CMAX65/132 | CMAX80/156 | CMAX80/156 | CMAX92/188 |

Extruder power | 18.5kw | 37kw | 37kw | 55kw | 110kw |

Extrusion capacity | 120kg/h | 250kg/h | 250kg/h | 360kg/h | 800kg/h |

Max. Production speed | 12m/min | 10m/min | 6 m/min | 3 m/min | 1.2m/min |

Process flow

PVC powder + additive → mixing → spring feeding → twin screw extruder → mould and calibrator →

vacuum forming machine → haul off machine → cutting machine → discharging rack

Capacity: Conical twin-screw extruder, suitable for process PVC powder with high capacity, max 1000kg/h

Diameter: from 16mm to 800mm

Auxiliary machine closely meet customer specifications. Nice out-look, automatic control and stable running performance

Application

PVC pipe is mainly used in the agricultural water supply and drainage, water supply and drainage construction, cable supporting, thickness of pvc plastic pipe, The lines have conical twin-screw extruder, vacuum calibration tank, haul-off machine, cutting machine, stacker or belling machine and so on. Haul-off machine have two caterpillar, three caterpillar, and four caterpillar, six caterpillar, the cutter use knife-raised cutter or planetary cutter which support chamferring function. And the stacker take into account length, production line is reliable performance, and high quality, we have exported to Egypt, Brazil, Syria, Uzbekistan etc.

Features

1) Main machine uses PVC twin screw, and notch feeder with powerful water

cover cooler, which has greatly improved transmitting capability and ensured

extruding.

2) Adopting double pipe extrusion method, it can greatly increase productivity.

3) Adopting high efficiency double-cavity vacuum calibrating technology and spray-paint

cooler gullet, which improve the finished product passing rate, and meet

the requirements of high speed manufacturing. Vacuum calibrating platform and cooler

gullet are all made of stainless steel

4) Adopting multi-caterpillar haul-off, through the central motor to run all the caterpillar

to reach same height, and ensure roundness of pipes

5) Adopting fully automatic control system with high precision, reliable operation,

easy and convenient handling

6) Suitable pipe diameter: 20 - 630mm

System configuration:

(a) Feeding machine

(b) Conical twin-screw extruder

(c) Mould

(d) Vacuum calibrating tank

(e) Hauling off machine

(f) Printing machine

(g) Pipe cutting machine

(h) Pipe pile-up frame

(i) Auxiliary machine such as mixer, water chiller, belling machine and crushing machine.

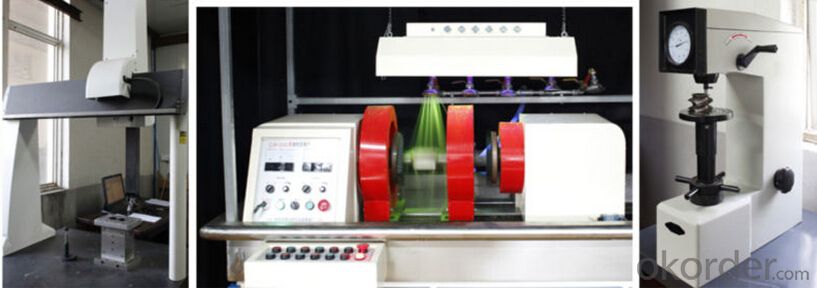

Product show

Our machine types:

1. Co-Rotating Parallel Twin Screw Pelletizing Extruders

2. Single Screw Pelletizing Extruders

3. Die Face Cut (Air Cooling) Pelletizing Extruders

4. Double Stage / Double Degassing Recycling Extruders

5. Crushers, Mixers, Storage Tanks, Vibrators, Granulators, Blowers

6. Extruder spare parts

FAQ

PVC sheet extrusion

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: producing polyethylene polypropylene fiber, masterbatch in the dark spot under the light, that is, masterbatch does not change, filter replacement frequently, half an hour... 40The equipment is Changzhou Riyue extruding machine, production of polyethylene polypropylene masterbatch, a dark spot in the light, it is not frequent replacement of masterbatch, filter plugging, half an hour, I added the 30% filling masterbatch, how to solve this problem? Other particles are not wet either. Masterbatch is not turned for help

- Is that settled? This technology is not available online! No one wants to say free, need technical contact me!

- Q: Produce 10 square wires with the smallest extruder

- If it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q: Can PC and PP be extruded together with two materials in an extruder?

- No co extrusion, PC polycarbonate, PP polypropylene, two kinds of product structure is not the same, not the same chemical composition, viscosity and liquidity is not the same, processing temperature and processing technology is also very different, and two kinds of products, so not incompatible, CO extrusion.

- Q: Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- 1. injection molding2., the structure is relatively complex, high appearance requirements. Extrusion does not meet requirements3. most are: ABS, ABS+PC, PP and so on4., according to color requirements granulation - drying particles - filling the mold ---- debugging injection molding machine ---- injection molding production - after the selection of finished packaging (if silk screen requirements, but also the need for silk screen)

- Q: Extrusion machine operating procedures, specific points, thank you!

- 11 prohibit the use of hand to touch the dry test machine high-voltage appliances, electrical wiring or ground wire parts.No water on the 12 wire core.13, do not stop before the hand touch insulated wire core, wire connector and exposed parts; after high voltage breakdown, the wire core should first take discharge measures, and then repair.14 driving and parking should be directed by skilled workers to avoid misuse and risk.15, equipped with softening equipment, plastic machine, the operator can not arbitrarily move, adjust electrical and mechanical equipment; can not touch the wire, electric pulley, copper catheter parts.16 after the end of the drive, the power supply, water source and air source should be all closed, and the operation handle will be replaced in place, and the records of the shift shift will be kept in good order.

- Q: What is the principle of the 45 extruder machine?

- The principle of the extruder is the theoretical process of heating, melting and mixing in the process of plastic conveying, including solid conveying principle, melt transportation principle, mixing principle, and solid bed crushing process, etc..

- Q: What are the components of an extruder?

- The driving system of an extruder is to drive the screw, providing the torque and speed required by the screw in the extrusion process, usually consisting of an electric motor, a reducer, and a bearing.3. heating and cooling device for extruderHeating and cooling are necessary conditions for the process of making a plastic extruder. It includes two aspects:(1) now host extruder is usually divided into electric heating, resistance heating and induction heating, heating installed in the fuselage, neck, head of each part. The heating device heats the plastic in the outer barrel to increase the temperature required for the process operation.(2) the cooling device is designed to ensure that the plastic is in the temperature range required by the process. Specifically, to eliminate the excess heat generated by the shear friction of the screw rotation, in order to avoid the temperature is too high, so that plastic decomposition, coke burning or stereotypes difficult. Cylinder cooling water cooling and air cooling is divided into two kinds, small and medium sized extrusion machine adopts air cooling is more appropriate, large use more water or two kinds of combined cooling; cooling water cooling screw mainly adopts the center, the purpose is to increase the solids conveying rate, stable glue volume, and improve product quality; but in the cooling hopper one is, in order to strengthen transport of solid material, prevent warming plastic sticky jam outlet, two is to ensure the normal work of the transmission part.

- Q: Does anyone know the operating procedures for the cable 65+120 extruder?

- What are the operating specifications for the extruder?One is the equipment instructionTwo is the boot operation specificationsThree is safety instructions and so onThe equipment manufacturer will provide the above

Send your message to us

PVC Pipe Line Plastic Pipe Extrusion With CMAX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords