CMAX Conical Twin-screw Plastic Extruder For High-speed Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

conical twin-screw extruder for high speed profiles is successfully developed by our company according to the market and clients’ demands, Mainly used to produce PVC door & window profiles etc, mainly for supporting high-speed extrusion line, a mode double out production line or windowsill board extrusion line and so on. Such kind of extruder is welcomed by the users with high output, extrusion stability, low- energy consumption.

Advantage:

High flexibility through gentle, homogeneous plasticization

AC motors for low energy consumption

A choice of different screw geometries for processing customer-specific PVC compounds

Low maintenance screw and an air-cooled barrel

Powerful gearbox; robust and compact design

Excellent price-performance ratio

Packaging & Shipping:

Packaging: PE film wrapped around & wooden pallet or wooden case worthy for long distance sea and land transportation ;

Delivery: 30 working days after receiving down-payment.

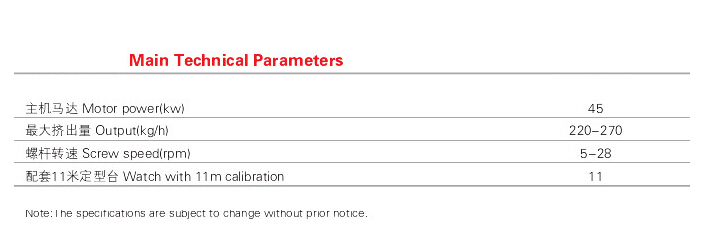

Technical Data:

Company Information

CNBM International Corporation

(CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.With the advantages in Cement, Composite Materials, New Building Materials and Engineering, We are enlarging sub-brand. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. In line with the business, CNBM International launched E-business platform Okorder.com. It conformed the best resource and logistics to meet the customers’ request with 24 hours full-time service.

Our Vision: Initiate new global trading structure; create new value for benefit related partners.

We will do utmost to promote rational use of resources under the new structure, meanwhile, create new value of “green, environment friendly and sustainable’ for a more prosperous future.

CNBM International Co. Carpet Dept.

At CNBM International Co. Carpet Dept., we design and weave beautiful carpets of superb durability - with axminster, tufted and wilton carpets to suit all hospitality environments. · There is no size limitation on rug size. Rugs can be created with a variety of materials from pure wool to woolen silk, from natural fiber to chemical fiber.

- Q: Basic parameters of extruder screw

- 2. The ratio of the length to diameter of the screw, the length of the screw L/Ds and the ratio of L to the diameter of the screw Ds is called the ratio of length to diameter. When the other conditions are constant (such as the diameter of the screw), increasing the ratio of length to diameter means increasing the length of the screw. The L/Ds value is large and the temperature distribution is reasonable, which is beneficial to the mixing and plasticizing of plastics. At the same time, the heating time of the plastic in the barrel is longer, and the plasticization of the plastic will be sufficient and more uniform. So as to improve the quality of machine plastics. If the plastic quality requirement is constant, the rotation speed of the screw can be increased after the ratio of length to diameter increases, thereby increasing the extrusion amount of the plastic. However, too large length diameter ratio, power consumption will increase the screw, and the screw and barrel of the processing and assembly of chicken more difficult; the possibility of screw bending will increase, will cause the abrasion of the screw and the inner wall of the cylinder, reduce the service life. In addition, the heat sensitive plastic, large diameter and long retention time than thermal decomposition, the plasticizing and impact plastic extrusion quality. Therefore, in the full use of the advantages of increasing the ratio of length to diameter, the selection should be based on the physical properties of the processed plastics and the quality requirements of the products.

- Q: What impact does the extruder vacuum pump open or close on the extrusion product?

- If the vacuum pump does not open, it may cause bubbles in the extruded product.

- Q: What are the common extrusion molding products?

- A plastic pipe, including water supply and drainage pipe, casing and other electrical B plastic doors and windows just C a variety of wire, cable, cable break, also includes a data line, wire headset D PVC ceiling e for plastic guardrail protection f roadside flowers and some decorative strips, temporary thought so much, there are a lot of specific products and you look at the things around you can think of

- Q: Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- I am a professional pipe mold, can you say more details?

- Q: What is the adjustment method of China's extrusion machine die?

- (2) run mode: plastic glue on the plasticizing after adjustment for mold screw, die according to how much glue circle, ran glue, side adjustment, adjustment should be loose thin screws, tighten the screws run glue thick; at the same time sampling check plastic thickness is eccentric, until evenly so far, then tighten the screw die respectively.

- Q: Extrusion blow molding machine, storage or continuous type good?

- The amount of extrusion must be continuous, efficient, and wasteful

- Q: Before and after the original good tune, up and down again before and after the tune, before and after, and up and down again

- The nose is not accurate enough or wornOr the screws are not screwed in placeOr die inappropriate, too large

- Q: Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- because itself is not suitable for the design of double cone, adjustment of the formula is the key.

- Q: Who knows the temperature regulation method of the extruder?Any information will do

- Extrusion molding in plastic processing is called extrusion, using hydraulic pressure in rubber extruder processing in extrusion die extrusion. That itself means that the material through the extruder barrel and screw the function between the side heating plasticization, screw edge is pushed forward, a processing method of continuous head made by various sections of finished or semi-finished products.In the fiber chemical industry is also useful in the extruder to the spinneret for melt spinning. The material, process of extrusion used in thermoplastic plastics and rubber, for batching, granulation, rubber filtration, continuous production, manufacturing various continuous products such as pipe, profile, sheet (or sheets), thin film wire and cable coating, rubber tire, tube noodles barrel, a sealing strip, the production efficiency is high. In the production of synthetic resin, can be used as reactor extruder, continuous polymerization and processing, in rubber industry, the compression ratio of different extruding machine can be used to unmasticated natural rubber of different materials. Compression extrusion machine than some different. [edit this paragraph] the principle of extrusion molding material since the bucket into the barrel, the screw rotates under the action of the cylinder wall and the surface of the screw friction shearing forward delivery to the feeding section in the loose. Forward transport also is compacted; the compression section, screw groove depth, further compaction, while the barrel heating and screw and cylinder wall friction shear, the material temperature rise began to melt, the compression section ends; homogeneous section material uniform, constant temperature, fixed quantity, squeeze out to melt. After a head forming, by setting the product.

Send your message to us

CMAX Conical Twin-screw Plastic Extruder For High-speed Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords