HDPE/PP/PVC Horizontal Type Double Wall Corrugated Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | According to your requirements |

| Delivery Detail: | 7-21 workings days after received your prepayment |

Properties:

HDPE/PP/PVC horizontal type DWC pipe extrusion line produced by CNBM has many patents. Full automatic control, running stable, high capacity. HDPE/PP material use high efficient single screw extruder, and PVC material use conical twin screw extruder or parrallel twin screw extruder. Horizontal type corrugator adopt advanced shuttle-type structure, closed water cooling system, on-line belling. Whole line is controlled by PLC computer.

Plastic Corrugated Pipe Features:

1. High tensile strength, compressive resistance and well impact resistance;

2. Anti-uneven settling property, and can be applicable to soft clay shifting sand foundation;

3. Convenient for connection with non-breakable joint.

4. Smooth inner wall, high friction resistance, large quantity of water flowing.

5. Decay resistance, "green pipe", avoid secondary pollution.

6. Light weight, easy for carrying and transporting, convenient for construction with low comprehensive cost.

Plastic Corrugated Pipe Advantages:

1. High density, good compression resistance and good impact resistance;

2. Good resistance of asymmetrical bedding, available being buried in the mollisol and quicksand;

3. Rubber ring connection, easy but no leakage in the joint;

4. Smooth interior wall and low friction, high flow capacity;

5. Good corrosion resistance and no environment pollution;

6. Application: municipal sewage; rainwater discharge; floodwaters drainage; irrigation; ventilation for mine and buildings; industrial waste discharge.

Plastic Corrugated Pipe Applications:

1. Civil engineering

2. Agricultural irrigation

3. Conveying system for sewage plant

4. Pre buried piping under highway

5. Ventilation piping for chemical industry and mine

6. Power telecommunication cable conduit

7. Bridge construction

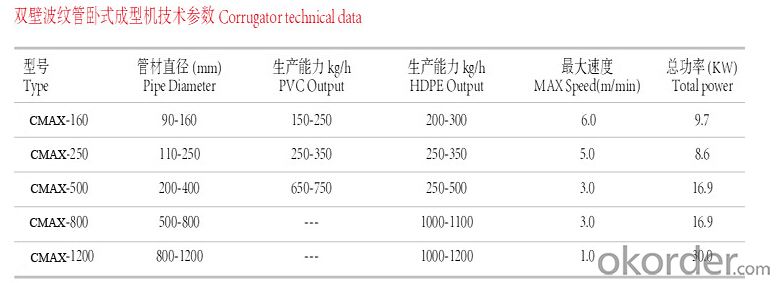

Technical parameters:

Main Products

- Q: What is the waste gas produced by the extruder, granulator and mixer?

- Plastic is a chemical product, and the waste gas produced by the process is organic waste gas. The commonly used and relatively efficient treatment method is activated carbon adsorption. The specific work process is as follows: exhaust gas, air pipe, dry filter, activated carbon adsorption, fan and discharge

- Q: What is an extruder?

- This method of forming is continuous molding, such as pipes, plastic profiles, films and so onThe machine also has a single screw, twin-screw, multi screw points.The forming methods are single extrusion and coextrusion only.

- Q: What impact does the extruder vacuum pump open or close on the extrusion product?

- If the vacuum pump does not open, it may cause bubbles in the extruded product.

- Q: What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q: PLC based extrusion machine control system design graduation thesis and PLC based injection molding machine control system thesis content?

- I can help you with this design.Select the topic according to the academic direction. The key to the value of thesis writing lies in the ability to solve specific problems in a particular industry, especially in academic terms. Therefore, one of the techniques for selecting and refining titles is to select and refine them according to their academic value.

- Q: Before and after the original good tune, up and down again before and after the tune, before and after, and up and down again

- The nose is not accurate enough or wornOr the screws are not screwed in placeOr die inappropriate, too large

- Q: Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q: The working principle of an extruder

- What is the working principle of an extruder?:Screw with specific shape,Turn in a heated barrel,It will be delivered from the hopperThe plastic is pressed forward, allowing the plastics to be uniformly plasticized (i.e., melted)Through the head and different shapes of the mold, the plastic extrusionA continuous plastic layer of various shapes, extruded on the core and cable.

- Q: What is the principle of the 45 extruder machine?

- The principle of the extruder is the theoretical process of heating, melting and mixing in the process of plastic conveying, including solid conveying principle, melt transportation principle, mixing principle, and solid bed crushing process, etc..

- Q: Does anyone know the operating procedures for the cable 65+120 extruder?

- Operating procedures are based on the preparation of equipment instructions, you can increase some of the preparatory work before the boot, the middle is the operation of equipment instructions, and finally must have safe and civilized operation instructions!

Send your message to us

HDPE/PP/PVC Horizontal Type Double Wall Corrugated Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches