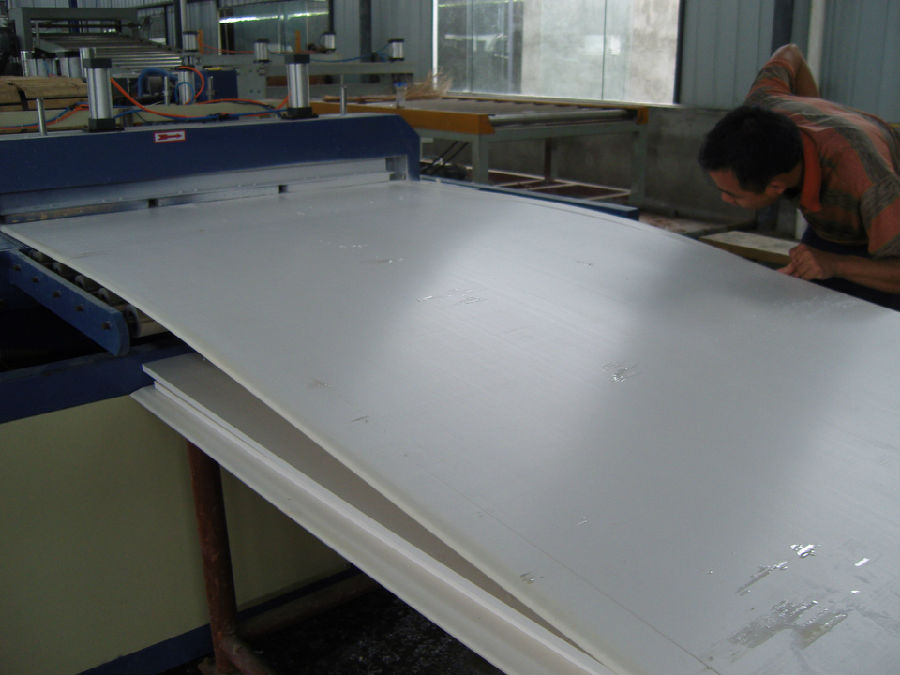

PVC skinning foam board shuttering plywood extrusion line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC skinning foam board extrusion line

Extruding product characteristics:

1). Waterproof, antiflaming, dampproof, rotproof, mothproof, light weight, keep temperature, sound and heat insulation and shockproof etc;

2). Color-way is not changed long time and not easy to aging under radiation resistance;

3). This product can be manufactured by general wood processing tools. It can be drilled, sawed, nailed and dig. It is the best substitute to raw wood, aluminum and composite product;

4). It can be welded as every general welding stipulation and also can be stick to other PVC materials.

5). It has smooth surface and is easy to print.

Technical configuration Specification of Pvc foam board Machine

| ||||

Name | Description | DETAILS | ||

1 | SJSZ 80/156 Conical twin Screw Extruder | ABB frequency converter, SIEMENS conto actor, OMRON Japan | ||

2 | Mould | hanger type extruding mould “EKO” | ||

3 | Foaming Machine | 4 phase calibrating device(hydraulic) | ||

4 | Cooling tank and bracket | Length:6000mm + Trimming knife: 3 sets | ||

5 | Haul-off unit Gear transmission | 8 couples (Cylinder clamping and loosening) | ||

6 | Automatic Cutting unit | 1set (controlled by ABB inverter) | ||

7 | Stacker machine | 1set | ||

8 | Colling Chiller 20P | 1set | ||

9 | Dust exhaust device | 2 sets | ||

Auxiliary machine | ||||

1 | 500/1000Mixer | 500L or 1000 L mixer (controlled by Inverter) | ||

2 | 500 Grinder | feeder controlled by ABB Inverter, with automatic dust collector | ||

3 | SWP 380 Crusher | rotation blades 9 pcs | ||

ATTENTION | ||||

1 | Main motor frequency controller : siemens or ABB | |||

2 | Temperature controller : OMRON or RKC | |||

3 | AC controller : Schneider or simens(As customer requirement) | |||

4 | Thermal overload relay : Schneider | |||

5 | Switch : DELIXI or Schneider | |||

6 | All electrical units on components from standard companies like OMRON/RKC/Siemens | |||

After-sales service

Technical documents

All labels on machines and lay-out drawings, Electrical diagram, User Manual, will be in English.

RUNJIA should send all necessary files to the buyer since the third week since project execution.

All documents in hard copies should be also shipped with machines together.

Arrangement for inspection, installation and testing work

a. After all machines are delivered to customer’s factory; Buyer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc.

b. Engineer will give free training lessons to labors in buyer’s factory.

Quantity and quality guarantee

a. Quantity/Quality Discrepancy to destination port during transportation:

b.Guarantee period and after-sales services: 12 months since date of bill of lading

During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us.

Long-term service:

we will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

- Q: Basic parameters of extruder screw

- 2. The ratio of the length to diameter of the screw, the length of the screw L/Ds and the ratio of L to the diameter of the screw Ds is called the ratio of length to diameter. When the other conditions are constant (such as the diameter of the screw), increasing the ratio of length to diameter means increasing the length of the screw. The L/Ds value is large and the temperature distribution is reasonable, which is beneficial to the mixing and plasticizing of plastics. At the same time, the heating time of the plastic in the barrel is longer, and the plasticization of the plastic will be sufficient and more uniform. So as to improve the quality of machine plastics. If the plastic quality requirement is constant, the rotation speed of the screw can be increased after the ratio of length to diameter increases, thereby increasing the extrusion amount of the plastic. However, too large length diameter ratio, power consumption will increase the screw, and the screw and barrel of the processing and assembly of chicken more difficult; the possibility of screw bending will increase, will cause the abrasion of the screw and the inner wall of the cylinder, reduce the service life. In addition, the heat sensitive plastic, large diameter and long retention time than thermal decomposition, the plasticizing and impact plastic extrusion quality. Therefore, in the full use of the advantages of increasing the ratio of length to diameter, the selection should be based on the physical properties of the processed plastics and the quality requirements of the products.

- Q: producing polyethylene polypropylene fiber, masterbatch in the dark spot under the light, that is, masterbatch does not change, filter replacement frequently, half an hour... 40The equipment is Changzhou Riyue extruding machine, production of polyethylene polypropylene masterbatch, a dark spot in the light, it is not frequent replacement of masterbatch, filter plugging, half an hour, I added the 30% filling masterbatch, how to solve this problem? Other particles are not wet either. Masterbatch is not turned for help

- This is often called information information, this website. Reference: Fox information Qilu Chemical City PE market by the petrochemical price driven price continues to rise, 7042 no tax 9350-9400 yuan / ton, 02TN26 no tax,

- Q: Produce 10 square wires with the smallest extruder

- If it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q: What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q: Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- I am a professional pipe mold, can you say more details?

- Q: 1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 1: extruder, is threaded through the push rod, the plastic die forming process by melting in the forward process. After the extruder products are silk, belt, tube, plate, etc. 2: injection molding machine, mainly to melt the plastic injection molding process, after the mold injection molding machine outjection. The main products are mechanical parts, containers, household appliances shell.

- Q: Before and after the original good tune, up and down again before and after the tune, before and after, and up and down again

- The nose is not accurate enough or wornOr the screws are not screwed in placeOr die inappropriate, too large

- Q: Is the extruder the same as the extruder?

- Extrusion machine, also called extruder, and is mainly used for power line, power cable, coaxial cable, communication cable, transmission cable, BV type civil line, electronic wire, computer wire, building line, data communication cable, RF cable, HDMI cable, cable, all kinds of high temperature silicone Teflon, core line line, network cable, optical fiber, rubber insulated wire cable wire and cable extrusion wire and cable equipment.

- Q: The working principle of an extruder

- What is the working principle of an extruder?:Screw with specific shape,Turn in a heated barrel,It will be delivered from the hopperThe plastic is pressed forward, allowing the plastics to be uniformly plasticized (i.e., melted)Through the head and different shapes of the mold, the plastic extrusionA continuous plastic layer of various shapes, extruded on the core and cable.

- Q: Who knows the temperature regulation method of the extruder?Any information will do

- Extrusion molding in plastic processing is called extrusion, using hydraulic pressure in rubber extruder processing in extrusion die extrusion. That itself means that the material through the extruder barrel and screw the function between the side heating plasticization, screw edge is pushed forward, a processing method of continuous head made by various sections of finished or semi-finished products.In the fiber chemical industry is also useful in the extruder to the spinneret for melt spinning. The material, process of extrusion used in thermoplastic plastics and rubber, for batching, granulation, rubber filtration, continuous production, manufacturing various continuous products such as pipe, profile, sheet (or sheets), thin film wire and cable coating, rubber tire, tube noodles barrel, a sealing strip, the production efficiency is high. In the production of synthetic resin, can be used as reactor extruder, continuous polymerization and processing, in rubber industry, the compression ratio of different extruding machine can be used to unmasticated natural rubber of different materials. Compression extrusion machine than some different. [edit this paragraph] the principle of extrusion molding material since the bucket into the barrel, the screw rotates under the action of the cylinder wall and the surface of the screw friction shearing forward delivery to the feeding section in the loose. Forward transport also is compacted; the compression section, screw groove depth, further compaction, while the barrel heating and screw and cylinder wall friction shear, the material temperature rise began to melt, the compression section ends; homogeneous section material uniform, constant temperature, fixed quantity, squeeze out to melt. After a head forming, by setting the product.

Send your message to us

PVC skinning foam board shuttering plywood extrusion line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords