UPVC Pipe And CPVC Solid Solid Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Our pipe extrusion line can be used to produce PVC, HDPE, and HDPP pipes with the diameter between 12mm and 400mm. The well-coordinated components, coupled with auxiliary machines, allow this pipe production line to produce pipes for different purposes, including drain pipes, water supply pipes, electrical conduits, PVC fire-retardant pipes, as well as piping for use in chemical industry.

Working flow:

Mixer→ Vacuum feeding →Material dry → Single screw extruder →Marking line extruder(co-extrusion)→Vacuum calibration spraying cooling tank → Spraying cooling tank→ Color-ribbon printer → Haul-off machine →Cutter →Stacker

Packaging & Delivery

| Packaging Detail: | plastic film package or according to customers' demand |

| Delivery Detail: | 30 days after receiving 30% advanced payment |

Specifications

1.Easy to operation and running steadily

2.Good after-service

3.Preferential price

4.Advanced Design

Main charaters:

This line can solve the problems of high temperature melting, high viscosity, easy-decomposition. The

special designed screw, gearbox, tooling, and HMI system make the line reliable and easy operation.

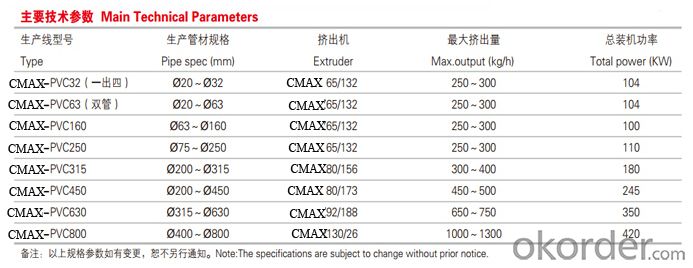

Main Technical Parameters

If you are interested in our product, please be free to contact us.Whether we could cooperate, we would do our best to help you. I’m confident that will be benefit to you and us!

FAQ:

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the diameter of pipe(inch or mm); thickness of pipe wall(mm); width and thickness of sheet (mm)? If profile product, you’d better offer the picture of sample or drawing of sample.

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

- Q: What is the waste gas produced by the extruder, granulator and mixer?

- Plastic is a chemical product, and the waste gas produced by the process is organic waste gas. The commonly used and relatively efficient treatment method is activated carbon adsorption. The specific work process is as follows: exhaust gas, air pipe, dry filter, activated carbon adsorption, fan and discharge

- Q: producing polyethylene polypropylene fiber, masterbatch in the dark spot under the light, that is, masterbatch does not change, filter replacement frequently, half an hour... 40The equipment is Changzhou Riyue extruding machine, production of polyethylene polypropylene masterbatch, a dark spot in the light, it is not frequent replacement of masterbatch, filter plugging, half an hour, I added the 30% filling masterbatch, how to solve this problem? Other particles are not wet either. Masterbatch is not turned for help

- This is often called information information, this website. Reference: Fox information Qilu Chemical City PE market by the petrochemical price driven price continues to rise, 7042 no tax 9350-9400 yuan / ton, 02TN26 no tax,

- Q: Wire and cable extrusion machine temperature exceeds the process documentation, what are the reasons?

- The temperature tolerance of the process file is too lowChanges in the formula of plastics lead to changes in processing temperatureThe workshop operator failed to execute the document

- Q: What are the common extrusion molding products?

- A plastic pipe, including water supply and drainage pipe, casing and other electrical B plastic doors and windows just C a variety of wire, cable, cable break, also includes a data line, wire headset D PVC ceiling e for plastic guardrail protection f roadside flowers and some decorative strips, temporary thought so much, there are a lot of specific products and you look at the things around you can think of

- Q: the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Is the fitting of the moving parts normal?.Is there an impact on the extrusion chamber?.

- Q: Comparison of injection molding machines and Extruders

- Considerations for extruder use:1, extrusion machine is running forward, avoid reverse2, avoid fasting operation, must heat engine feeding operation, so that can avoid sticking bar (holding shaft) phenomenon3, the extruder inlet, vent hole is strictly prohibited access to iron and other miscellaneous, so as not to cause accidents, affect production4, safe use of electricity, grounding wire5. When the machine is running, it is forbidden to touch the rotating parts such as the material inlet, the material outlet, the belt, the gear and so on6, before using the machine should be injected with lubricating oil, so as not to cause damage to the machineSince the extruder as one of the three synthetic plastic material since the advent of rapid development.

- Q: Is the extruder the same as the extruder?

- The extruder is also called in the screw extruder is under the action of the molten plastic extrusion through fixed shape extrusion, water cooling after cutting in the traction machine under the same section is mainly used for a variety of products.

- Q: why production is not strong?I have several new co extrusion machines, but the blown plastic bags are not produced by others

- The recipe is either too large or too small. Do you mean that the tension is not enough, transverse or vertical?

- Q: How many roots are produced in an hour for an PVC tube extruder?

- It depends on the type of your extruder and the specification of the tube you produced

- Q: Ask everyone about the extrusion machine at the wire factory...... How do you adjust the speed of the motor?

- The outer diameter is big...... I've got the tractor switched 1600 and the engine is switched 1400Chasing the answerThe extruding worker sees the line, cannot see the speed meter, the speed meter sometimes is not allowedLarge diameter, you can reduce the speed of the main engine or speed up the traction, in addition, the maximum current of the host can not exceed 2 times the power rating of the motor, more than two times will burn the motor.AskI've finished pulling the button.

Send your message to us

UPVC Pipe And CPVC Solid Solid Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords