Base Reinforcement Geogrids - Plastic Uniaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

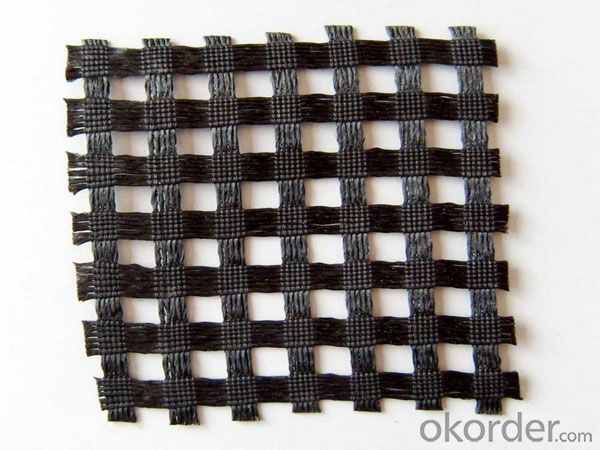

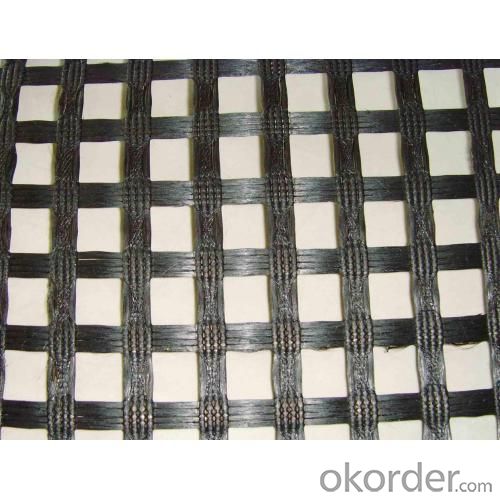

Structure of Plastic Uniaxial Geogrid Description:

Plastic Uniaxial Geogrid provide equal strengths in both machine and cross directions making them suitable for bases or foundation application where stresses can occur in any direction. Depending upon manufacturing techniques and materials, geogrids can be designed to resist creep when subjected to high loads for long periods of time or resist high, short-term dynamic loads or moderate loads over longer periods of time。

Main Features of Plastic Uniaxial Geogrid :

High tensile strength at low elongation

Optimized grid structure

Excellent pull-out and interface friction behavior

Superior connection capacity with modular blocks

Long durable years

High corrosion resistance

High flame retardancy,Fire prevention

High static conductive property

Easy in transport and installation..

Plastic Uniaxial Geogrid Images

Plastic Uniaxial Geogrid Specification:

1.Plastic Uniaxial Geogrid for Reinforced soil engineering(reinforced soil retaining wall, steep slope and the reinforcement and consolidation of the soft ground);

2.Road construction(ground treatment, reinforcement of the bridge abutment, reinforcement of the enbankment, reinforcement of the pile-net roadbed)

3. Geogrids for Irrigation projects(protection of port, approach lane, seabeach, channel, river channel, dam and other irrigation projects.)

4. Enviromental projects(land reclamation, prevention and controlling of the desertification,and the composite protective structure in the landfill sites of urban garbage and waste)

5. Mine engineering grid for long-wall recovery system(coal mines, side slope protection of opencast mines, slope protection for the dumping site of the opencast mines,reinforcement to counter dam in the large tailing ponds of the metallurgical mines)

6. Construction of stuffing and package system of heavy soil engineering

7. slope protection in the area affected by earthquake

8. Ground consolidation of large dump leaching sites and slag site

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: How do geogrids improve the performance of geocell-reinforced slopes?

- Geogrids improve the performance of geocell-reinforced slopes by providing additional strength and stability to the structure. They help distribute the load more evenly across the geocell system, preventing soil erosion and reducing the risk of slope failure. Geogrids also increase the overall tensile strength of the geocell-reinforced slope, making it more resistant to external forces such as water flow or seismic activity.

- Q: How much is the tensile strength of geogrid???????

- Divided into three categories: the overall plastic stretch: two-way products: 15KN--50KN one-way products: 50KN---300KN

- Q: Can geogrids be used in ground stabilization for telecommunications infrastructure?

- Yes, geogrids can be used in ground stabilization for telecommunications infrastructure. Geogrids are commonly used in civil engineering projects to reinforce and stabilize soil, making them suitable for supporting the weight and load of telecommunications infrastructure such as towers, poles, and cables. They can effectively improve the soil's strength and prevent settlement, ensuring the stability and longevity of the infrastructure.

- Q: Can geogrids be used in reinforcement of tunnels and underground excavations?

- Yes, geogrids can be used in the reinforcement of tunnels and underground excavations. Geogrids are often installed to provide additional support and stability to the surrounding soil or rock mass, reducing the risk of collapse or deformation. They can help distribute the applied loads and increase the overall strength of the structure, making them a suitable choice for reinforcing tunnels and underground excavations.

- Q: Geogrid what to do

- Longitudinal transverse tension

- Q: How to choose 15kn bidirectional geogrid geogrid

- First of all, in the choice of geogrid types, according to the construction project categories selected, according to the environmental impact of the project in which the same project many times in different environments with different types of grid.

- Q: How do geogrids improve the performance of geosynthetic-reinforced slopes in seismic zones?

- Geogrids improve the performance of geosynthetic-reinforced slopes in seismic zones by providing additional stability and reinforcement to the soil. They act as a strengthening element within the slope, enhancing its resistance to the dynamic forces generated during seismic events. The geogrids effectively distribute the loads throughout the slope, reducing the potential for slope failure or displacement. This reinforcement mechanism helps to maintain the integrity and overall stability of the slope, mitigating the adverse effects of seismic activity.

- Q: What is the meaning of the highway geogrid gsl50/hdpe

- Hi ~ ~ ~ ~ on the high-speed use of geogrid, nothing more than two kinds, a kind of roadbed with geogrid, a kind of pavement with geogrid, you said that GS150 is certainly the roadbed with steel plastic geogrid,

- Q: Can geogrids be used in soil reinforcement for pipeline projects?

- Yes, geogrids can be used in soil reinforcement for pipeline projects. Geogrids are commonly used in civil engineering projects to improve soil stability and prevent soil erosion. They are effective in providing reinforcement and reducing the potential for soil settlement, making them suitable for enhancing the stability of pipelines in various soil conditions.

- Q: What are the design considerations for geogrids in mechanically stabilized earth walls?

- Some of the key design considerations for geogrids in mechanically stabilized earth (MSE) walls include selecting the appropriate geogrid material and strength, determining the required geogrid spacing and length, considering the connection and anchorage details, assessing the interface friction between the geogrid and the soil, and evaluating the long-term durability and performance of the geogrids in the specific environmental conditions. Additionally, proper installation practices and quality control measures should be implemented to ensure the geogrids are correctly positioned and tensioned within the MSE wall system.

Send your message to us

Base Reinforcement Geogrids - Plastic Uniaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords