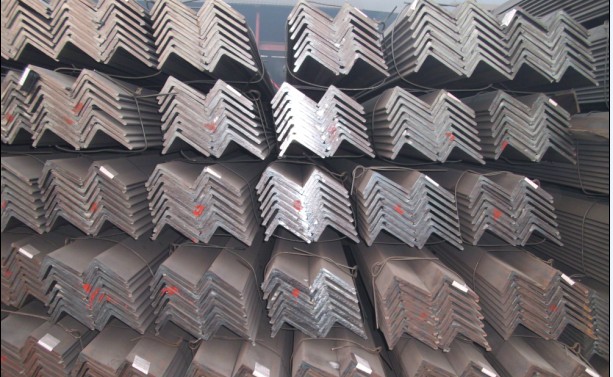

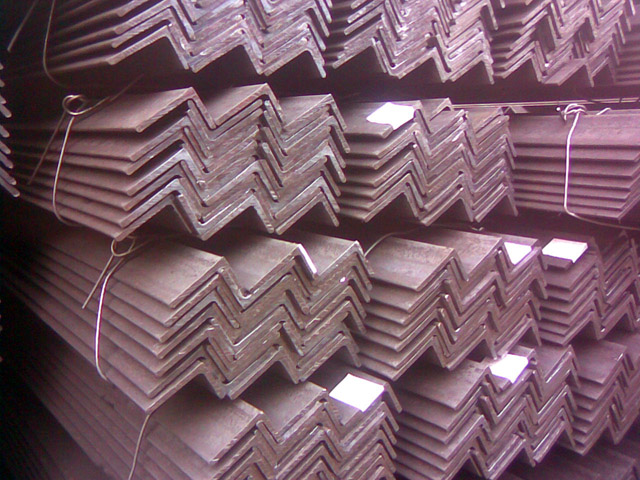

Unequal Stainless Steel 304 Angle Bars or Angle Iron Steel Fabrication

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

High alloy stainless steel with excellent high-temperature oxidation resistance and high-temperature strength.Specifications

stainless steel angle

Certification: ISO

Place of Origin: Shanxi, China (Mainland)

Model Number: angle bar

Standard: AISI, ASTM, DIN, GB, JIS

stainless steel angle

| Product | Competitive price stainless steel angle |

| Product classification | Equal Angle Steel & Unequal Angle Steel |

| Production Technics | Hot rolled,cold-bend |

| Productivity | 300,000 Mt/Year |

| Main Material | cold drawn stainless steel bar: Dia 1.0-12.0mm,bright surface. hot rolled stainless steel bar: Dia 14.0-150mm,black surface. forged stainless steel bar: Dia 150-350mm, unsmooth surface. |

| Surface treatment | hot dip galvanised or cold dip galvanised |

| Specification | (20*20*2mm)-(200*200*25mm) |

| Theoretical weight per meter | =0.00785*(width+width-thickness)*thickness |

| Application | widely used in Power tower, communication tower, railway, highway, street lamp pole, marine parts, construction steel structure component, handling machinery ,Container frame , warehouse ,reaction tower,the substation ancillary facilities, light industry etc. |

| Length | 6m-12m as you require |

Stainless Steel Angle Bar

1. Material grade:

cold drawn stainless steel bar: Dia 1.0-12.0mm,bright surface.

hot rolled stainless steel bar: Dia 14.0-150mm,black surface.

forged stainless steel bar: Dia 150-350mm, unsmooth surface.

2. Standard: ASTM A276,A484,A564,A581,A582,EN10272,JIS4303,JIS G 431,JIS G 4311,JIS G 4318,stainless steel angle bar

3. Production procedure: raw elements(C,Fe,Ni,Mn,Cr,Cu etc.,)-- smelted ingots by AOD finery-- hot rolled into black surface--pickling into acid liquid--cutting into pieces--checking quality--package

4. Surface: black,pickling,polish, etc ., stainless steel angle bar

5. Common sizes we have large stocks,diameter from 10mm*10mm*2mm-300mm*300mm*20mm

6. Usage:stainless steel angle bar is widely used in chemical, shipping,architecture,machine-made, household products industry, etc.

Definition of stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steelalloy with a minimum of 10.5% to 11% chromium content by mass.

Stainless steel does not readily corrode, rust or stain with water as ordinary steel does, but despite the name it is not fully stain-proof, most notably under low oxygen, high salinity, or poor circulation environments. It is also called corrosion-resistant steel or CRES when the alloy type and grade are not detailed, particularly in the aviation industry. There are different grades and surface finishes of stainless steel to suit the environment the alloy must endure. Stainless steel is used where both the properties of steel and resistance to corrosion are required.

- Q: Are steel angles suitable for architectural applications?

- Indeed, architectural applications are well-suited for steel angles. In construction and architectural projects, steel angles are frequently employed due to their adaptability, robustness, and visual allure. They serve a multitude of purposes, including the formation of structural frames, supports, connections, and even decorative elements. Architects are provided with a wide range of options when it comes to steel angles, as they are available in various sizes, thicknesses, and finishes, enabling the selection of the most appropriate choice in accordance with specific design requirements. Moreover, steel angles can be effortlessly welded, drilled, and manipulated to accommodate diverse angles and shapes, thus rendering them a versatile and economical alternative for architectural applications.

- Q: How do you determine the torsional stiffness of a steel angle?

- In order to find the torsional stiffness of a steel angle, one must take into account both its geometry and material properties. The first step involves calculating the polar moment of inertia (J) of the steel angle. This value represents the shape's resistance to torsion and can be determined by summing the products of the differential area elements and their distances squared from the axis of rotation. For a steel angle, one can utilize standard formulas or reference tables to obtain the polar moment of inertia. Subsequently, the material properties of the steel angle, particularly its modulus of rigidity (G), need to be determined. The modulus of rigidity measures the material's ability to resist deformation under shear stress. This information is usually provided by the steel manufacturer or can be sourced from material property databases. Once the polar moment of inertia has been calculated and the modulus of rigidity has been obtained, the torsional stiffness (K) can be determined using the formula K = G * J. The torsional stiffness signifies the steel angle's capacity to withstand twisting or torsional deformation when subjected to a torque. It is important to bear in mind that the torsional stiffness of a steel angle can vary depending on factors such as its size, shape, and the specific steel alloy used. Therefore, it is advisable to consult relevant design codes or engineering references to ensure accurate calculations and take into account any additional factors that may impact the torsional stiffness.

- Q: Can steel angles be used as structural members?

- Certainly, structural members can utilize steel angles. In construction and engineering endeavors, steel angles are frequently employed to furnish structural reinforcement and stability. They are commonly utilized to fortify and enhance an assortment of structures, including edifices, bridges, and frameworks. Renowned for their robustness and endurance, steel angles are highly suitable for structural applications. They can be utilized either in combination with other steel components or independently to bear or distribute loads, bolster beams, and confer stability to the overall structure. Moreover, steel angles can be conveniently fabricated and installed, rendering them a versatile and cost-effective choice for structural members in diverse construction projects.

- Q: Can steel angles be used for soundproofing applications?

- No, steel angles cannot be used for soundproofing applications.

- Q: Are steel angles suitable for manufacturing support brackets for pipes?

- Yes, steel angles are suitable for manufacturing support brackets for pipes. Steel angles are known for their strength, durability, and load-bearing capacity, making them an ideal choice for supporting and securing pipes in various applications. The angled shape of steel angles provides stability and structural integrity to the support brackets, ensuring that the pipes remain securely in place. Additionally, steel angles can be easily fabricated, welded, and customized to meet specific requirements, making them a versatile and cost-effective option for manufacturing support brackets for pipes.

- Q: How do you specify steel angles in drawings?

- To properly describe steel angles in drawings, it is necessary to specify several crucial factors. First and foremost, the dimensions of the angle must be clearly indicated. This can be achieved by specifying the lengths of the legs or the dimensions of the equal sides. For instance, an angle measuring 3 inches by 3 inches with a thickness of 1/4 inch would be denoted as a 3" x 3" x 1/4" angle. The type of angle should also be specified, whether it is L-shaped or unequal. This information is vital in determining the most suitable steel angle for a particular application. Furthermore, it is essential to indicate the grade of the steel angle. Steel angles are available in various grades, each possessing different levels of strength and durability. Common grades include A36, A572, and A588, among others. The grade is typically specified to ensure that the angle meets the required structural or mechanical properties. The length of the steel angle is another significant parameter that must be stated in the drawing. Whether it is a fixed length or a specific range, this information facilitates accurate fabrication and installation. Lastly, any additional requirements or specifications, such as surface finish, tolerance, or specific treatments or coatings, should be clearly stated in the drawing. This ensures that the steel angle is manufactured and installed according to the desired specifications. By including these parameters in the drawings, engineers, fabricators, and contractors can easily identify and procure the necessary steel angles for construction or manufacturing purposes with precision.

- Q: What are the different types of surface defects in steel angles?

- Steel angles can be affected by various types of surface defects, which can have negative effects on their appearance, strength, and overall quality. Common surface defects in steel angles include: 1. Scale: When steel is exposed to high temperatures during manufacturing or processing, a thin layer of iron oxide, known as scale, can form on its surface. Scale not only affects the appearance of the steel but can also lead to corrosion if not removed. 2. Pits: Small depressions or cavities on the steel surface, known as pits, can be caused by corrosion, improper handling, or manufacturing defects. Pits weaken the steel and reduce its overall strength. 3. Scratches: Grooves or marks on the steel surface caused by abrasion or contact with other objects are referred to as scratches. While scratches may not affect the structural integrity of the steel, they can impact its appearance and serve as potential starting points for corrosion. 4. Inclusions: Non-metallic particles or impurities that become trapped within the steel during the manufacturing process are called inclusions. Inclusions can weaken the steel, leading to reduced strength and potential failure under load. They can be caused by improper steelmaking techniques or the presence of foreign materials. 5. Laminations: Layers or sheets of metal that are improperly bonded together during the manufacturing process are known as laminations. Improper rolling or welding techniques can cause laminations to occur. Laminations weaken the steel, reducing its strength and potentially causing failure. 6. Corrosion: When steel is exposed to moisture and oxygen, a chemical reaction known as corrosion occurs, resulting in the formation of rust or other corrosion products on the steel surface. Corrosion weakens the steel and reduces its overall integrity. To ensure the quality and performance of steel angles, it is important to identify and address these surface defects. Regular inspection, proper handling, and appropriate surface treatment can help minimize the occurrence and impact of these defects.

- Q: How do you determine the load-bearing capacity of a steel angle?

- To determine the load-bearing capacity of a steel angle, several factors need to be considered. Firstly, the material properties of the steel angle must be known, such as its yield strength and ultimate tensile strength. These values can be obtained from the manufacturer or from relevant material standards. Next, the dimensions and shape of the steel angle play a crucial role in determining its load-bearing capacity. The angle's thickness, width, and length should be measured accurately. Additionally, the angle's shape, whether it is equal or unequal, must also be taken into account. Once these properties are known, the load-bearing capacity can be calculated using engineering principles and structural analysis methods. One common approach is to use the Euler's formula, which considers the bending and axial loads on the steel angle. The Euler's formula states that the load-bearing capacity of a steel angle is proportional to its moment of inertia and the modulus of elasticity. These values are calculated based on the dimensions and shape of the angle. Furthermore, other factors such as the angle's end supports, the type of loading (e.g., concentrated load or uniformly distributed load), and any additional factors of safety must be taken into consideration. It is important to note that determining the load-bearing capacity of a steel angle is a complex process that requires expertise in structural engineering. Therefore, it is recommended to consult with a qualified engineer or refer to relevant design codes and standards to ensure accurate and safe calculations.

- Q: Are steel angles suitable for vehicle ramps?

- Yes, steel angles are suitable for vehicle ramps. Steel angles are commonly used in construction and are known for their strength and durability. They provide a sturdy and stable surface for vehicles to drive on, making them a suitable choice for vehicle ramps. Additionally, steel angles can be easily welded or bolted together to create a customized ramp design that meets specific requirements. Overall, steel angles are a reliable and practical option for constructing vehicle ramps.

- Q: What are the different methods of reinforcing steel angles?

- There are several methods of reinforcing steel angles, each with its own advantages and applications. One common method is the use of additional steel plates or brackets. These plates or brackets are typically welded or bolted to the existing steel angle to provide additional support and strength. This method is often used in applications where the steel angle is subject to high loads or stresses. Another method is the use of stiffeners, which are typically smaller steel angles or plates welded perpendicular to the existing angle. These stiffeners help to distribute the load more evenly and prevent the steel angle from buckling or bending under stress. This method is often used in applications where the steel angle is used as a structural member, such as in building frames or bridge supports. Additionally, reinforcing steel angles can be achieved through the use of concrete encasement or composite materials. In this method, the steel angle is embedded within a concrete matrix or combined with other materials such as fiberglass or carbon fiber. This combination provides enhanced strength, durability, and resistance to corrosion. This method is commonly used in construction projects where the steel angle is exposed to harsh environments or requires high performance. Overall, the different methods of reinforcing steel angles provide options for increasing the strength, stability, and durability of these structural components. The choice of method will depend on the specific application, load requirements, and environmental factors.

Send your message to us

Unequal Stainless Steel 304 Angle Bars or Angle Iron Steel Fabrication

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords