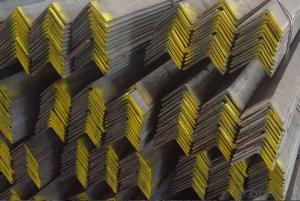

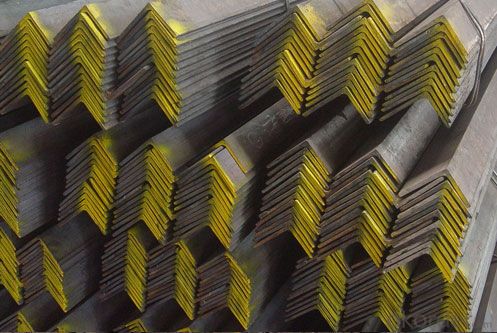

Unequal Angle Steel Factory Price Carbon Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Unequal Angle Steel Factory Price Carbon Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Angle Steel Factory Price Carbon Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Angle Steel Factory Price Carbon Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

HOT SALE CARBON STEEL ANGLES MOQ:1 TON

1. Competitive price

2. Good quality

3. Fast delivery

4. Best service

Standard Sectional Dimension mm mm | Weight kg/m | Standard Sectional Dimension mm mm | Weight kg/m |

25*25*3 | 1.12 | 90*90*6 | 8.28 |

30*30*3 | 1.36 | 90*90*7 | 9.59 |

40*40*3 | 1.83 | 90*90*10 | 13.3 |

40*40*5 | 2.95 | 100*100*7 | 10.7 |

45*45*4 | 2.74 | 100*100*10 | 14.9 |

45*45*5 | 3.38 | 100*100*13 | 19.1 |

50*50*4 | 3.06 | 120*120*8 | 14.7 |

50*50*6 | 4.43 | 130*130*9 | 17.9 |

60*60*4 | 3.68 | 130*130*12 | 23.4 |

60*60*5 | 4.55 | 130*130*15 | 28.8 |

60*60*6 | 5.37 | 150*150*12 | 27.3 |

65*65*6 | 5.91 | 150*150*15 | 33.6 |

65*65*8 | 7.66 | 150*150*19 | 41.9 |

70*70*6 | 6.38 | 175*175*12 | 31.8 |

75*75*6 | 6.85 | 175*175*15 | 39.4 |

75*75*9 | 9.96 | 200*200*15 | 45.3 |

80*80*6 | 7.32 | 200*200*20 | 59.7 |

80*80*7 | 8.48 | 200*200*25 | 73.6 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel angles be used for storage racks?

- Yes, steel angles can be used for storage racks. Steel angles are commonly used in the construction of storage racks due to their strength, durability, and ability to support heavy loads. They provide stability and structural integrity, making them suitable for storing various items in a safe and organized manner.

- Q: What's the size of No. 5 angle iron?

- The size of No. 5 angle steel is: steel with length, width and height of 50*50*xmm, wherein X can be 3mm, 4mm, 5mm.

- Q: What are the different types of connections used for steel angles in steel frames?

- There are several types of connections used for steel angles in steel frames, including welded connections, bolted connections, and riveted connections. Welded connections involve fusing the angles together using heat, creating a strong and permanent bond. Bolted connections involve using bolts and nuts to secure the angles together, allowing for easy disassembly if necessary. Riveted connections involve using rivets, which are metal pins, to hold the angles together by forming a permanent, tight fit. The choice of connection type depends on the specific requirements of the steel frame and the desired level of strength and durability.

- Q: What are the different types of steel angles used in structural engineering?

- In structural engineering, various types of steel angles are commonly used for their versatility and strength. These steel angles are typically made from carbon steel or stainless steel and come in a variety of shapes and sizes to suit specific structural applications. Some of the different types of steel angles used in structural engineering include: 1. Equal Leg Angles: Also known as L-shaped angles, these angles have equal dimensions for both legs, forming a 90-degree angle. Equal leg angles are commonly used as structural components in building frames, supports, and bracing systems. 2. Unequal Leg Angles: These angles have different lengths for each leg, creating an unequal angle. Unequal leg angles are often used in applications where a larger load-bearing capacity or specific structural requirements are necessary. 3. Angle Iron: Angle iron is a general term used to describe various steel angles that have been rolled into a 90-degree angle. It is commonly used as a structural element in construction projects, such as framing, bracing, and supports. 4. Slotted Angles: Slotted angles are a variation of angle iron that feature holes or slots along the length of the angle. These holes provide flexibility for attaching other structural components or accessories, making them versatile for shelving, racks, and workbenches. 5. Stainless Steel Angles: Stainless steel angles are made from corrosion-resistant stainless steel alloys. They are commonly used in applications where strength, durability, and resistance to corrosion are essential, such as in marine, food processing, and chemical industries. 6. Rolled Steel Angles: Rolled steel angles are manufactured by rolling steel plates or sheets to form an angle shape. They are widely used in construction projects due to their high strength-to-weight ratio and cost-effectiveness. 7. Structural Steel Angles: Structural steel angles are designed specifically for structural applications, such as supporting beams, columns, and trusses. These angles are typically made from high-strength carbon steel and are available in various sizes and thicknesses to meet specific load-bearing requirements. Overall, the different types of steel angles used in structural engineering provide engineers with a wide range of options to design and construct robust and efficient structures. The selection of the appropriate angle depends on factors such as load requirements, structural design, and environmental conditions.

- Q: What are the different types of connections used for steel angles in structural applications?

- Steel angles in structural applications can be connected using various types of connections. These connections play a crucial role in maintaining the stability and strength of the overall structure. Firstly, welded connections are commonly used. This method involves fusing the edges of the steel angles together through melting, resulting in a strong bond. Welded connections are ideal for applications that require high strength and rigidity. Secondly, bolted connections provide flexibility as they involve using bolts and nuts to secure the steel angles. This type of connection allows for easy disassembly and reassembly if needed. Bolted connections are often chosen for their ease of installation and maintenance. Thirdly, riveted connections are a traditional method of joining steel angles. This involves inserting a rivet through holes in the steel angles and flaring the ends to secure them. Although riveted connections are known for their durability and resistance to corrosion, they are less commonly used today due to the time-consuming installation process. Next, clip connections utilize metal clips or brackets to attach the steel angles quickly and efficiently. These clips can be welded or bolted to the angles, making them suitable for applications where speed and ease of installation are important. Lastly, gusset plate connections involve using steel plates to connect the steel angles at their intersection points. These plates are typically welded or bolted to the angles, enhancing the strength and stability of the connection. Gusset plate connections are often employed when larger forces and moments need to be transferred. It is essential to consider the specific needs of the structure, including the structural requirements, loadings, and the intended application, when choosing the appropriate connection method. Adhering to design and engineering specifications ensures that the selected connection method is suitable for the desired use in structural applications.

- Q: What is the maximum bending moment for a steel angle?

- The maximum bending moment for a steel angle depends on various factors such as the dimensions, material properties, and loading conditions. It cannot be determined without specific information about the angle and the forces acting on it.

- Q: What is the maximum length for a curved steel angle?

- The maximum length for a curved steel angle can vary depending on various factors such as the thickness of the steel, the degree of curvature, and the specific application requirements. It is best to consult with a structural engineer or steel fabrication expert to determine the appropriate maximum length for a curved steel angle in a particular situation.

- Q: Can steel angles be galvanized or coated for corrosion resistance?

- Yes, steel angles can be galvanized or coated with a protective layer for corrosion resistance. Galvanizing involves applying a zinc coating to the steel surface, while coating can involve various materials such as paint or powder coating. These treatments help to prevent rust and enhance the longevity and durability of steel angles in corrosive environments.

- Q: Can steel angles be recycled or reused?

- Certainly, steel angles have the ability to be recycled and reused. Steel, being extremely durable and valuable, is among the most frequently recycled materials worldwide. Once steel angles are no longer necessary or become scrap, they can be gathered, organized, and dispatched to recycling facilities. The recycling procedure entails melting down the steel angles to eliminate impurities, after which the molten steel is molded into fresh products. Recycled steel angles are applicable in numerous industries, including construction, automotive, and manufacturing, just like newly manufactured steel angles. This not only preserves natural resources but also aids in reducing energy consumption and greenhouse gas emissions linked to the production of new steel. Recycling steel angles is an efficient method to encourage sustainability and contribute to a circular economy.

- Q: Can steel angles be used in historical or heritage restoration projects?

- Historical or heritage restoration projects can indeed utilize steel angles. With their versatility, steel angles can serve various purposes, including structural support, reinforcing, and decorative detailing. By fabricating them to match the original design and materials of historical structures, seamless integration with the existing architecture can be achieved. Strength, durability, and resistance to corrosion are among the advantages that steel angles offer, making them particularly valuable in restoration projects that aim to preserve the historical integrity of the structure. Moreover, steel angles can be tailored and manufactured to meet specific project needs, making them suitable for a wide array of restoration applications.

Send your message to us

Unequal Angle Steel Factory Price Carbon Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords