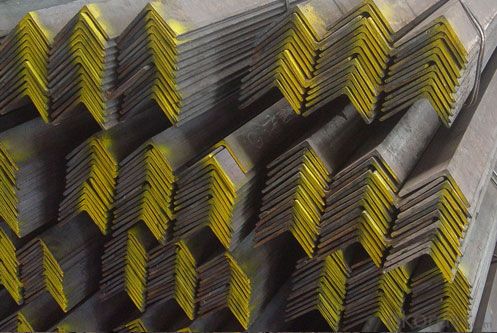

Unequal Angle Bar Steel China High Quality for Engineering Structure

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Unequal Angle Bar Steel China High Quality for Engineering Structure at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Angle Bar Steel China High Quality for Engineering Structure are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Angle Bar Steel China High Quality for Engineering Structure are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

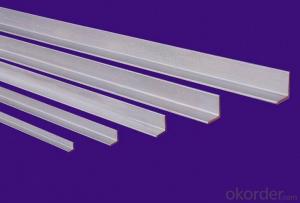

Product Specifications:

angle steel

1 Material: Q195-Q345,SS400,S235JR

2. Sizes: 25*25*- 250*250*35

3.Manufacturer,specialized since 2004

Product Description | |

Product | carbon hot rolled steel angle |

Grade | Q195, Q215, Q235, Q345, SS400, A36, S235JR, ST37,etc |

Standard | AISI, ASTM, BS, DIN, GB, JIS, etc |

Equal Angle | 1)Type: 2#-20# 2)Size: 20mm-200mm 3)Thickness: 3.0mm-24mm |

Unequal Angle | 1)Type: 2.5/1.6-20/12.5 2)Long Side: 50-200mm 3)Short Side: 32-125mm 4)Thickness: 4.0-18mm |

Length | 5.8m-12.0m or as your requirement |

Usage | Widely used in various building structure and engineering structure |

Technique | Hot rolled |

Place of origin | Tangshan China (Mainland) |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel angles be used in sign support structures?

- Absolutely! Sign support structures can definitely utilize steel angles. These angles are widely employed in construction owing to their remarkable robustness and endurance. They offer exceptional support and stability, rendering them ideal for various applications, including sign support structures. By welding or bolting steel angles together, a strong framework can be effortlessly created for sign mounting. Furthermore, their exceptional load-bearing capacity is crucial in guaranteeing the sign's security and stability, particularly during unfavorable weather conditions. Moreover, steel angles can be tailored to meet specific design specifications, making them a versatile option for sign support structures.

- Q: What are the different types of steel angles used in shelving units?

- Shelving units commonly utilize various types of steel angles. The most basic type is the L-shaped angle, which forms the frame of the unit with its 90-degree angle. Slotted angles, on the other hand, resemble L-shaped angles but possess holes or slots along their length. These openings allow for convenient adjustment of shelving height and flexibility in configuration. Equal angles, featuring legs of equal length, are commonly found in shelving units with steel or heavy-material shelves. They provide extra strength and support to the shelves. Unequal angles, with legs of different lengths, are often used in shelving units housing lighter materials like wood or plastic. These angles ensure stability and prevent shelf sagging under the weight of items. Slotted equal angles combine the adjustability of slotted angles with the added strength of equal angles. They are frequently employed in shelving units that require both adjustability and strength. Ultimately, the choice of steel angles for shelving units depends on specific requirements such as load capacity, adjustability, and the material used for the shelves.

- Q: Can steel angles be painted or coated for aesthetic purposes?

- Yes, steel angles can be painted or coated for aesthetic purposes. Painting or coating steel angles can enhance their appearance and provide protection against corrosion. The process usually involves cleaning the surface of the steel angles to remove any dirt, oil, or rust, and then applying a primer and paint or a specialized coating. The choice of paint or coating will depend on the desired aesthetic and the environmental conditions the steel angles will be exposed to. By painting or coating steel angles, they can be customized to match the surrounding decor or architectural design, making them more visually appealing and blending seamlessly into the overall aesthetic.

- Q: What is the meaning of the number of angle steel

- The model does not mean the size of the different edges and sizes of the same model. Therefore, the width, the edge and the thickness of the angle iron should be filled out in the contract and other documents, so as not to be indicated by the model alone. The specification for hot rolled equilateral angle iron is No. 2 - 20.

- Q: What is the maximum deflection allowed for a steel angle?

- The maximum deflection allowed for a steel angle depends on various factors such as the specific application, the load applied, and the desired safety factor. However, as a general guideline, the maximum deflection allowed for a steel angle is typically limited to 1/360th of its span length.

- Q: What is the typical thickness of the base of a steel angle?

- The base thickness of a steel angle can vary depending on its specific application and requirements. Typically, the base thickness of a steel angle ranges from 1/8 inch to 3/8 inch. It is worth mentioning that this range is not comprehensive, and there may be instances where the base thickness deviates from these parameters. Elements such as the steel angle's size, load-bearing capacity, and intended purpose will impact the necessary base thickness for a particular project or structure. As a result, consulting engineering specifications or seeking professional guidance is crucial in determining the suitable base thickness for a steel angle in a specific application.

- Q: What are the different types of connections used for steel angles in structural applications?

- Steel angles in structural applications can be connected using various types of connections. These connections play a crucial role in maintaining the stability and strength of the overall structure. Firstly, welded connections are commonly used. This method involves fusing the edges of the steel angles together through melting, resulting in a strong bond. Welded connections are ideal for applications that require high strength and rigidity. Secondly, bolted connections provide flexibility as they involve using bolts and nuts to secure the steel angles. This type of connection allows for easy disassembly and reassembly if needed. Bolted connections are often chosen for their ease of installation and maintenance. Thirdly, riveted connections are a traditional method of joining steel angles. This involves inserting a rivet through holes in the steel angles and flaring the ends to secure them. Although riveted connections are known for their durability and resistance to corrosion, they are less commonly used today due to the time-consuming installation process. Next, clip connections utilize metal clips or brackets to attach the steel angles quickly and efficiently. These clips can be welded or bolted to the angles, making them suitable for applications where speed and ease of installation are important. Lastly, gusset plate connections involve using steel plates to connect the steel angles at their intersection points. These plates are typically welded or bolted to the angles, enhancing the strength and stability of the connection. Gusset plate connections are often employed when larger forces and moments need to be transferred. It is essential to consider the specific needs of the structure, including the structural requirements, loadings, and the intended application, when choosing the appropriate connection method. Adhering to design and engineering specifications ensures that the selected connection method is suitable for the desired use in structural applications.

- Q: What are the different types of steel angles used in door and window frames?

- The different types of steel angles commonly used in door and window frames include equal angle, unequal angle, L-shaped angle, and T-shaped angle.

- Q: Can steel angles be used as bracing elements in buildings?

- Yes, steel angles can be used as bracing elements in buildings. Steel angles are commonly used in construction for their strength and versatility. They are often used as structural components to provide lateral stability and support to buildings. Steel angles can be used as bracing elements to resist horizontal loads such as wind or seismic forces, helping to prevent excessive movement or deformation of the structure. They are typically installed at strategic locations, such as corners or intersections, and can be connected to other structural members using bolts or welds. Steel angles are preferred for bracing due to their high strength-to-weight ratio, durability, and ease of installation. Overall, steel angles are a reliable and commonly used solution for bracing elements in buildings.

- Q: Can steel angles be used in construction?

- Indeed, construction can utilize steel angles. Due to their versatility, strength, and cost-effectiveness, steel angles are frequently employed as structural elements in construction endeavors. Their primary purpose is to support and reinforce various structural components, including beams, columns, and walls. Various sizes and thicknesses of steel angles are available, allowing for a wide range of applications in construction. They can be easily joined together through welding, bolting, or fastening, facilitating convenient on-site installation and customization. A key advantage of incorporating steel angles in construction lies in their high strength-to-weight ratio. This attribute enables steel angles to possess outstanding load-bearing capacity while remaining relatively lightweight, rendering them highly suitable for structures that necessitate strength without excessive weight. Moreover, steel angles exhibit excellent durability and resistance against environmental factors such as corrosion, fire, and pests. Consequently, structures constructed with steel angles boast extended lifespans and require minimal maintenance over time. In summary, steel angles offer a versatile and dependable option for construction projects, regardless of whether they are residential, commercial, or industrial in nature. Architects, engineers, and contractors commonly favor steel angles due to their strength, durability, and ease of installation.

Send your message to us

Unequal Angle Bar Steel China High Quality for Engineering Structure

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords