High Quality Koyokuto DN230 Spectacle Wear Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

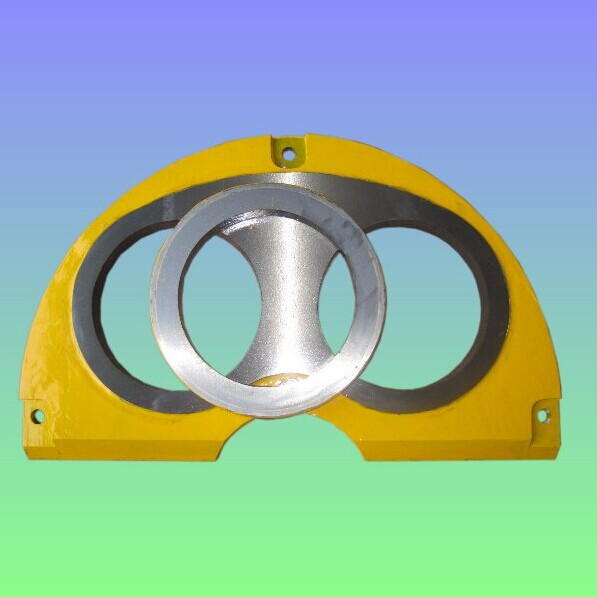

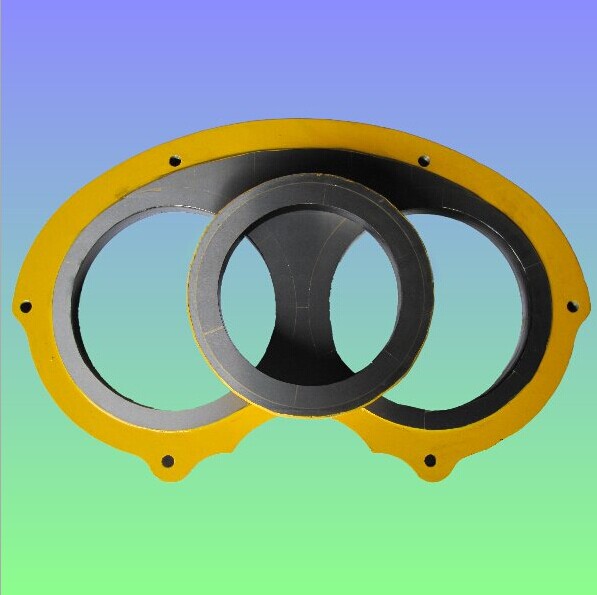

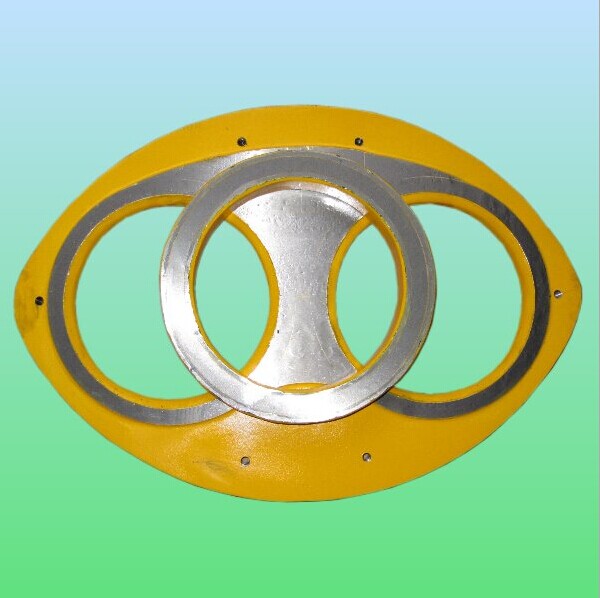

Product Name: High Quality Koyokuto DN230 Spectacle Wear Plate

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade.

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 25000 N/mm2

6. Application: trailer and trunk mounted Koyokuto concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our High Quality Koyokuto DN230 Spectacle Wear Plate have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs High Quality Koyokuto DN230 Spectacle Wear Plate put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some High Quality Koyokuto DN230 Spectacle Wear Plate according to customers request?

A4: Yes, we can produce High Quality Koyokuto DN230 Spectacle Wear Plate according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: How do I identify the right spare part for my concrete pump model?

- If you want to find the correct spare part for your concrete pump model, there are several steps you can take: 1. Begin by referring to the manufacturer's manual. This manual is a great starting point because it typically contains detailed information about your concrete pump model and the corresponding spare parts. Look for part numbers, descriptions, and any specific instructions regarding ordering or replacing parts. 2. Conduct online research. Utilize the internet to search for your specific concrete pump model and related spare parts. Many manufacturers have official websites or authorized distributors that provide product catalogs or online databases where you can search for the exact part you need. Look for compatibility charts or diagrams that match your concrete pump model with the appropriate spare parts. 3. Seek advice from a specialist. If you are uncertain about the compatibility or availability of spare parts for your concrete pump model, it is advisable to consult with a specialist. Reach out to the manufacturer's customer service or contact a local distributor or service center that specializes in concrete pumps. Provide them with details about your pump model and the specific part you require, and they should be able to assist you in identifying the correct spare part. 4. Speak with other concrete pump owners. Get in touch with other owners or operators of concrete pumps who have the same or a similar model as yours. They may have experience with finding and replacing spare parts and can offer recommendations or tips on where to search or who to contact. Remember, it is vital to ensure that the spare part you select is compatible with your concrete pump model to prevent any damage or malfunctions. Taking the time to conduct research and seek advice from experts will help you find the appropriate spare part and keep your concrete pump operating smoothly.

- Q: How often should wear rings be replaced in a concrete pump?

- The replacement frequency of wear rings in a concrete pump relies on various factors such as the pump type, wear ring quality, concrete volume being pumped, and operating conditions. In essence, wear rings are components that endure substantial wear and tear due to the abrasive nature of concrete. Consequently, they will eventually require replacement to uphold the pump's efficiency and avoid potential damage to other pump parts. Typically, wear rings should be regularly inspected during routine maintenance checks. The wear patterns and extent of damage will determine if replacement is needed. In certain cases, wear rings may endure for several thousand hours of operation, while in others, replacement may be necessary more frequently. It is advisable to consult the pump manufacturer for specific guidelines on wear ring replacement intervals based on the pump model and operating conditions. They can offer recommendations based on their expertise and understanding of the pump's design and performance. Ultimately, the objective is to guarantee smooth and efficient operation of the concrete pump, minimizing downtime and maximizing its lifespan. Regular inspections and proactive replacement of wear rings when necessary will contribute to achieving this goal.

- Q: Can concrete pump spare parts be replaced individually, or should they be replaced as a set?

- Concrete pump spare parts can be replaced individually, as there is no requirement to replace them as a set. This allows for more cost-effective and efficient maintenance, as only the specific part that needs replacement can be addressed.

- Q: How often should concrete pump remote control antennas be inspected and replaced?

- Concrete pump remote control antennas should be inspected regularly, preferably on a monthly basis, to ensure they are in good working condition. However, the frequency of replacement depends on several factors such as usage, environmental conditions, and wear and tear. It is recommended to replace the antennas if they are damaged, show signs of malfunction, or if there is a noticeable decrease in signal strength.

- Q: How can one identify the correct thread size and type for concrete pump spare parts?

- To identify the correct thread size and type for concrete pump spare parts, one can start by consulting the manufacturer's specifications and documentation. These resources often provide detailed information on the thread size and type used in the equipment. Additionally, measuring the existing thread on the spare part or the corresponding component can help determine the correct thread size and type. Utilizing thread gauges or consulting a professional in the industry can also provide accurate identification of the required thread size and type for concrete pump spare parts.

- Q: If the concrete pump valve jam how to judge and deal with?

- The valve plug is formed gradually, the main reason is that after the completion of concrete pump, no time to use high-pressure water washing, resulting in concrete residue in the tube after a considerable period of time, gradually thickening, accumulation of consolidation, resulting in congestion.

- Q: When concrete is poured, how high can the concrete pump be put?

- When the floor height exceeds the applicable height of the automobile pump, the ground pump (stationary pump) is used to pour and grind the concrete, and the height of the pump can reach more than 100 meters to two hundred meters

- Q: What are the common issues that require replacement of concrete pump spare parts?

- Concrete pumps can experience various issues that necessitate the replacement of spare parts. One prevalent problem is the gradual deterioration of pump components due to wear and tear. Continuous movement of concrete through the pump causes deterioration of parts like the piston, wear plate, and seals, which then need to be replaced. Another issue that may arise is blockages or clogs in the pump line. This occurs when hardened concrete or other debris accumulates, obstructing the flow of concrete. In such cases, replacing parts like the delivery pipe, hose, or even the entire pump line becomes necessary to ensure proper functioning. Leaks are also a common problem in concrete pumps. These leaks often result from damaged or worn-out seals, gaskets, or O-rings. If left unattended, leaks can lead to reduced pump performance and potential safety hazards. Replacing the affected parts helps prevent further damage and ensures efficient pump operation. Additionally, pump malfunctions can be attributed to electrical or mechanical issues. Faulty electrical components, such as switches or sensors, may require replacement to restore proper functionality. Mechanical problems, such as a worn-out gearbox or a malfunctioning hydraulic system, may also necessitate the replacement of specific pump parts. In summary, common issues that call for the replacement of concrete pump spare parts include wear and tear, blockages, leaks, electrical malfunctions, and mechanical failures. Regular maintenance and inspection of the pump enable early identification of these issues, allowing for timely replacement of the necessary spare parts to maintain smooth pump operation.

- Q: How can a malfunctioning control panel affect the pump's operation?

- A malfunctioning control panel can affect the pump's operation by causing errors in controlling the pump's speed, pressure, or flow rate. It can also lead to inaccurate monitoring of the pump's performance, failure to detect faults or abnormalities, and difficulty in troubleshooting issues. Ultimately, a malfunctioning control panel can compromise the pump's efficiency, reliability, and overall functionality.

- Q: How can a faulty lubrication system affect the pump's performance?

- A faulty lubrication system can significantly affect the pump's performance in several ways. Firstly, a lubrication system is responsible for providing a thin film of lubricant between moving parts of the pump, reducing friction and wear. If the lubrication system is faulty or inadequate, it can result in increased friction between components, leading to excessive heat generation and accelerated wear and tear. This can ultimately reduce the efficiency and lifespan of the pump. Secondly, a faulty lubrication system can cause inadequate lubrication to critical components, such as bearings and seals. Insufficient lubrication can lead to increased friction, heat, and ultimately, premature failure of these components. This can result in increased downtime, costly repairs, and potential damage to other parts of the pump. Furthermore, a faulty lubrication system can also result in the contamination of the lubricant. Contaminants such as dirt, debris, or moisture can enter the system due to leaks or improper maintenance. These contaminants can cause abrasive damage to the pump's internal components, leading to reduced efficiency, increased wear, and potential failure. Lastly, a faulty lubrication system can also impact the pump's overall performance and energy consumption. Insufficient lubrication can increase the power requirements of the pump as it works harder to overcome friction and resistance. This can result in higher energy consumption and increased operating costs. In conclusion, a faulty lubrication system can severely impact the pump's performance by causing increased friction, accelerated wear and tear, premature failure of critical components, contamination of the lubricant, and increased energy consumption. Regular maintenance and proper lubrication are crucial to ensure the pump operates at its optimal level and to extend its lifespan.

Send your message to us

High Quality Koyokuto DN230 Spectacle Wear Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords