Steel Prop & Beam Clamp formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

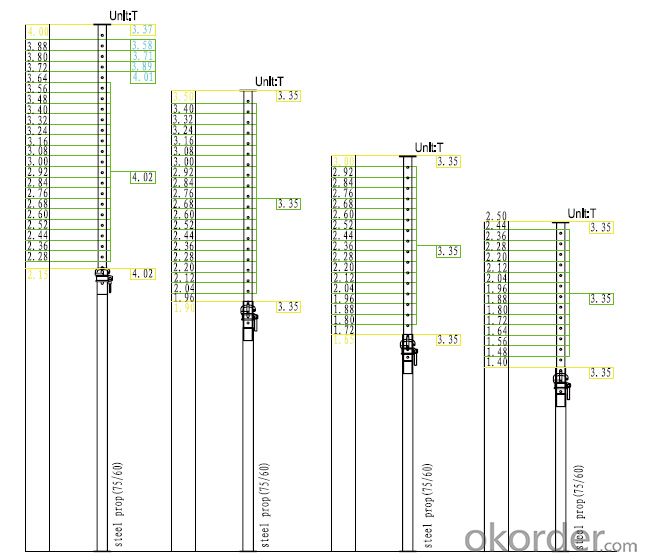

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Can steel props be used for temporary support in tunnels?

- Yes, steel props can be used for temporary support in tunnels. Steel props are commonly used in construction projects to provide temporary support to structures, including tunnels. They are designed to withstand heavy loads and provide stability during construction or maintenance activities. Steel props are adjustable, allowing them to be easily installed and removed as needed. Additionally, they can be customized to fit the specific dimensions and requirements of the tunnel project. Overall, steel props are a reliable and effective solution for providing temporary support in tunnels.

- Q: What safety precautions should be taken when using steel props?

- To ensure the safety of workers and prevent potential accidents or injuries, it is important to take several safety precautions when using steel props. The first step is to carefully inspect the steel props before use. Look for any signs of damage, such as cracks, bends, or corrosion. If any issues are found, replace or repair the props immediately with the help of a qualified professional. Next, assess the load-bearing capacity of the props. Make sure they are suitable for the intended purpose and can safely support the weight they will bear. Overloading the props can lead to structural failure and collapse, posing a significant risk to workers. Additionally, securely install and brace the props. Place them on a stable and level surface, using proper footplates to distribute the load. Tighten and lock the props securely to prevent accidental movement or collapse. Regular inspections and maintenance are essential. Check for wear and tear, loose bolts, or damaged components, and address them promptly. Regularly lubricate the moving parts of the props for smooth and safe operation. Establish clear communication and coordination among workers when using steel props. Provide adequate training to ensure everyone understands the proper procedures and safety precautions. Use clear signage and warning tapes to mark the area where the props are in use, preventing collisions or tripping hazards. Lastly, follow all relevant safety regulations and guidelines when using steel props. Adhering to local, national, and international standards will ensure the props are used safely and correctly. By following these safety precautions, the risk of accidents, injuries, and structural failures can be minimized, creating a safer working environment for all.

- Q: Can steel props be used for temporary support in residential buildings?

- Yes, steel props can be used for temporary support in residential buildings. Steel props are commonly used in construction to provide temporary support during building works, renovations, or repairs. They are adjustable and can bear heavy loads, making them suitable for providing temporary support in residential buildings where additional support is needed.

- Q: Can steel props be used in the construction of libraries?

- Yes, steel props can be used in the construction of libraries. Steel props, also known as adjustable steel props or steel scaffolding, are commonly used in construction projects to provide temporary support to structures. They are designed to bear heavy loads, making them suitable for supporting the weight of library structures and the load of books and other materials. Steel props are adjustable in height, allowing for flexibility during the construction process. Furthermore, steel props are durable, corrosion-resistant, and can be reused in multiple construction projects, making them a cost-effective choice. Overall, steel props can be safely and effectively used in the construction of libraries to provide structural support and enhance the overall safety and stability of the building.

- Q: Can steel props be used in historical or heritage restoration projects?

- Yes, steel props can be used in historical or heritage restoration projects. Steel props are commonly used in construction for temporary support and stabilization of structures. They are adjustable, strong, and can be easily customized to fit the specific requirements of the project. While traditional materials may be preferred for the restoration of historical or heritage buildings, steel props can be utilized in a careful and discreet manner to ensure minimal visual impact while providing the necessary structural support.

- Q: Can steel props be customized based on specific project requirements?

- Indeed, specific project requirements can be met through the customization of steel props. These adjustable telescopic columns are commonly employed to provide temporary support in construction or renovation endeavors. They come in a variety of sizes and load capacities, tailored to accommodate diverse project demands. Furthermore, steel props can be personalized in terms of length, diameter, and load-bearing capacity to precisely match specific needs. This flexibility empowers contractors and engineers to select the most suitable steel props for their projects, guaranteeing optimal safety and support. The customization options extend to adjustable features, including telescopic extensions, facilitating effortless adaptability to varying heights and configurations. All in all, the capacity to customize steel props renders them an indispensable and versatile tool within the construction industry.

- Q: What are the common signs of wear or damage on steel props?

- Common signs of wear or damage on steel props include visible dents, cracks or bending, rust or corrosion, loose or damaged adjustment mechanisms, and excessive wear on the base plates or pins.

- Q: How do you ensure proper stability when using steel props on inclined surfaces?

- Achieving proper stability when utilizing steel props on inclined surfaces necessitates adherence to several crucial steps: 1. Evaluate the angle of the inclined surface: Accurate determination of the inclined surface's angle is imperative prior to setting up the steel props. This can be accomplished by employing a leveling tool or a laser level to guarantee precise measurements. 2. Opt for suitable steel props: The selection of appropriate steel props is vital for stability. Confirm that the props possess an adequate load-bearing capacity to endure the weight and forces exerted upon them as a result of the incline. Consider employing adjustable props that can be extended or shortened as required to accommodate the slope. 3. Properly position the props: Precise positioning of the steel props is paramount for stability. Place the props at regular intervals along the inclined surface, ensuring they are firmly embedded into the ground or a stable base. 4. Provide supplementary support: In certain instances, additional support may be necessary to augment stability. This can be achieved by employing bracing or struts to connect the steel props and evenly distribute the load. Bracing aids in preventing any lateral movement or tilting of the props. 5. Utilize suitable base plates: Base plates play a crucial role in evenly distributing the props' load and preventing sinking or sliding. Verify that the base plates are securely affixed to the props and possess a sufficiently large surface area to ensure stability on the inclined surface. 6. Regularly inspect and maintain the props: Routine inspections of the steel props are essential to ensure their continued good condition and to identify any wear, damage, or corrosion that may compromise their stability. Immediate attention should be given to any signs of instability or weakness, and damaged props should be promptly replaced. 7. Seek professional guidance if necessary: When confronting particularly challenging or complex inclined surfaces, consulting with a structural engineer or construction professional is advisable to ensure the employment of correct methods and guarantee the stability of the props. By adhering to these steps, one can ensure proper stability when utilizing steel props on inclined surfaces, thereby minimizing the risk of accidents or structural failures.

- Q: How long can a steel prop be used on a construction site?

- The length of time a steel prop can be used on a construction site depends on various factors such as the quality of the prop, the load it is supporting, and the conditions it is exposed to. Steel props are commonly used for temporary support during construction, renovation, and repair works. They are designed to be adjustable in height, making them versatile for different applications. In general, steel props are durable and can be repeatedly used as long as they remain in good condition. However, it is important to regularly inspect the props for any signs of damage or wear and tear. If any defects are detected, the prop should be replaced immediately to ensure safety on the construction site. The lifespan of a steel prop can also be influenced by the load it is supporting. Props have weight limits specified by manufacturers, and exceeding these limits can compromise their structural integrity. Therefore, it is crucial to ensure that the props are used within their specified load-bearing capacity. Additionally, the environmental conditions in which the props are used can affect their longevity. Exposure to extreme weather conditions, chemicals, or corrosive environments can accelerate the deterioration of steel props. Regular maintenance and proper storage can help extend their lifespan. Ultimately, the length of time a steel prop can be used on a construction site is subjective and can vary depending on the above-mentioned factors. It is always recommended to follow the manufacturer's guidelines, conduct regular inspections, and prioritize safety to ensure the props are used efficiently and effectively throughout the construction project.

- Q: Can steel props be used for shoring purposes?

- Yes, steel props can be used for shoring purposes. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction to provide temporary support to structures, walls, or ceilings during renovation, repair, or construction work. These props can be easily adjusted to the required height and provide a stable and secure support system.

Send your message to us

Steel Prop & Beam Clamp formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords