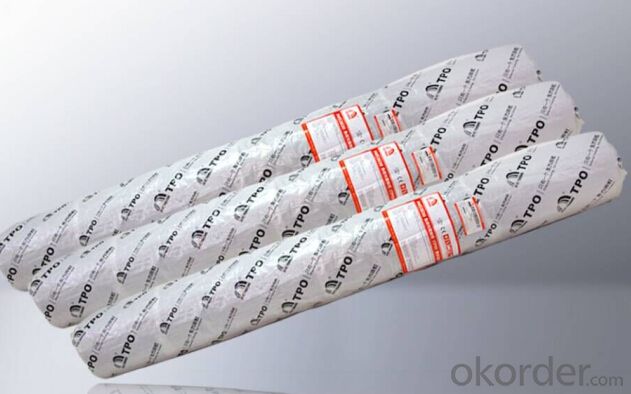

TPO Waterproof Membrane Professional Supplier for Thickness 1.2mm 1.5mm 2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TPO Waterproof Membrane

1. Introduction

TPO (Thermoplastic Polyolefin) waterproof membrane is typically based on polypropylene and EP (ethylene-propylene) rubber. TPO mainly contains carbon atoms and hydrogen atoms and does not contain any plasticizers and chlorine elements. It is a beautiful, long-lived environment-friendly product. TPO membranes are installed mechanically-attached, fully-adhered or ballasted.

2. Features

l It’s easy to install with good system integrity, few accessories.

l Excellent tensile strength, tearing resistance and penetration resistance performance..

l Hot-air welding. The peel strength of joint is high. Fast welding speed.

l Environment friendly, 100% recycled, without chlorine.

l Durable hot welding performance and easy to repair.

l Smooth surface, no fading and pollution.

Systems

Thanks to a variety of installation systems, the UltraPly TPO Roofing System can be used on the most challenging rooftops, for both renovation and new built applications.Product

The UltraPly TPO Roofing System consists of a light colored, environmentally friendly UltraPly TPO roofing membrane and a complete range of accessories. This combination offers a unique combination of features & benefits.Technical Information

We provides to distributors, contractors, specifiers and building owners a comprehensive range of technical documents, such as specifications, data sheets, type approvals and detail drawings.Installation

The installation guidelines help the contractor installing the UltraPly TPO Roofing System in accordance with Firestone's requirements.Training

The UltraPly TPO Roofing System is exclusively installed by approved roofing contractors that have successfully completed a training program in one of training centers.Project References TPO

Since the installation of the first UltraPly TPO roofs in the early nineties, hundreds of thousands of square meters of UltraPly TPO membranes have been installed worldwide. The project portfolio includes a selection of major projects.

3. Specification

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

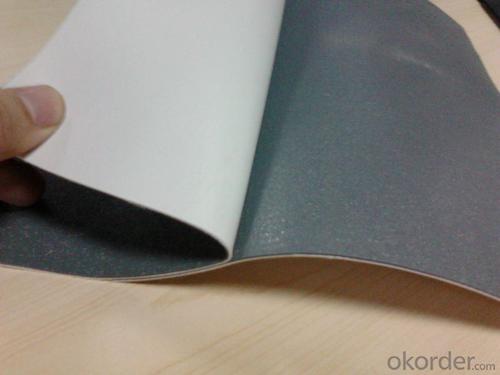

Type | Homogeneous, Internally reinforced with fabric, With fabric backing |

Color | White grey |

4. Applications

l Roof construction & steel structure of both industrial and civil engineering

l Underground engineering, such as subways, tunnels, air Raid shelter, etc.

l Sewage treatment, dam, reservoir and basement, grain storehouse, etc.

5. Classification

H- Homogeneous TPO membrane

L- TPO membrane with fabric backing

P- TPO membrane internally reinforced with fabric

6. Technical Data Sheet

TPO Waterproof Membrane | Standard: GB27789-2011 | |||||||

NO. | Item | Unit | Value | |||||

H | L | P | ||||||

1 | Resin Thickness on Middle Mesh ≥ | mm | - | - | 0.4 | |||

2 | Tensile Properties | Max. Strength ≥ | N/cm | - | 200 | 250 | ||

Tensile Strength ≥ | Mpa | 12.0 | - | - | ||||

Elongation at Max. Strength ≥ | - | - | 15 | |||||

% | 500 | 250 | - | |||||

3 | Dimensional Stability after Heat Treatment ≤ | % | 2.0 | 1.0 | 0.5 | |||

4 | Foldability at Low Temperature | -40℃ No cracks | ||||||

5 | Watertightness | 0.3Mpa, 2h No penetration | ||||||

6 | Resistance to Impact | 0.5kg*m, No penetration | ||||||

7 | Resistance to Static Loading | - | - | 20kgs No penetration | ||||

8 | Joint Peel Strength≥ | N/mm | 4.0 or membrane broken | 3.0 | ||||

9 | Right Angle Tearing Strength≥ | N/mm | 60 | - | - | |||

10 | N/mm | - | 250 | 450 | ||||

11 | Water Absorption (70℃, 168h) ≤ | % | 4.0 | 3.0 | ||||

12 | Aging in Hot Weather (115℃) | Time | 672h | |||||

Appearance | No bubbles, cracks, layering, sticky, hole | |||||||

Max. Tensile Retention Rate ≥ | % | - | 90 | |||||

Tensile Strength Retention Rate ≥ | % | 90 | - | - | ||||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 90 | ||||

Breaking elongation Retention rate | % | 90 | 90 | - | ||||

Low Temperature Flexibility | -40℃ No cracks | |||||||

13 | Chemical resistance

| Appearance | No bubbles, cracks, layering, sticky, hole | |||||

Max. Tensile Retention Rate ≥ | % | - | 90 | 90 | ||||

Tensile Strength Retention Rate ≥ | % | 90 | - | - | ||||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 90 | ||||

Breaking elongation Retention rate | % | 90 | 90 | - | ||||

Low Temperature Flexibility | -40℃ No cracks | |||||||

14 | Artificial aging | Time | 1500h | |||||

Appearance | No bubbles, cracks, layering, sticky, hole | |||||||

Max. Tensile Retention Rate ≥ | % | - | 90 | 90 | ||||

Tensile Strength Retention Rate ≥ | % | 90 | - | - | ||||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 90 | ||||

Breaking elongation Retention rate | % | 90 | 90 | - | ||||

Low Temperature Flexibility | -40℃ No cracks | |||||||

Remarks: l Resistance to static load is for TPO membranes used on roofing l The time of artificial aging of single-ply roofing membrane is 2500h. | ||||||||

Images of EPDM Rubber Waterproof Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Does a waterproofing membrane require any special considerations for installation in seismic zones?

- Yes, a waterproofing membrane does require special considerations for installation in seismic zones. Seismic zones are prone to earthquakes and ground movements, which can cause significant stress and strain on the building structure. When installing a waterproofing membrane in such areas, it is crucial to ensure that it can withstand the potential movements and vibrations caused by seismic activities. Some of the special considerations for installing a waterproofing membrane in seismic zones include: 1. Flexibility: The membrane should have sufficient flexibility to accommodate the movement of the building structure during an earthquake. It should be able to stretch, contract, and withstand dynamic forces without tearing or losing its waterproofing properties. 2. Compatibility: The waterproofing membrane should be compatible with the building materials and systems used in seismic zones. It is important to select a membrane that can bond well with the substrate and other construction components to create a seamless and robust waterproofing system. 3. Reinforcement: In high seismic areas, it is recommended to reinforce the waterproofing membrane with additional layers or reinforcements. This can be done by adding a fabric or mesh layer to enhance the membrane's tensile strength and resistance to tearing caused by seismic movements. 4. Proper installation techniques: The installation of the waterproofing membrane in seismic zones should follow specific guidelines and techniques to ensure its effectiveness. It may involve using specific adhesives, primers, or mechanical fastening systems to secure the membrane properly. 5. Quality control: Regular inspections and quality control measures should be implemented during and after the installation process. This helps to identify any potential issues or deficiencies in the waterproofing system, allowing for prompt repairs or adjustments to be made. By addressing these special considerations, the installation of a waterproofing membrane in seismic zones can help protect the building structure from water intrusion and potential damage caused by earthquakes. Consulting with experienced professionals and following industry standards and guidelines is crucial to ensure a successful installation in these challenging environments.

- Q: Can a waterproofing membrane be painted or covered with a protective layer?

- Yes, a waterproofing membrane can be painted or covered with a protective layer. This can help enhance its durability and resistance to external elements. However, it is important to ensure that the paint or protective layer used is compatible with the waterproofing membrane to maintain its effectiveness and prevent any potential damage.

- Q: Can a waterproofing membrane be used on elevator shafts?

- Yes, a waterproofing membrane can be used on elevator shafts. Elevator shafts are vulnerable to water infiltration, and using a waterproofing membrane can help prevent water damage and leakage into the shaft.

- Q: Can a waterproofing membrane be used for plant rooms?

- Indeed, plant rooms can benefit from the utilization of a waterproofing membrane. These rooms frequently accommodate machinery and equipment that necessitate safeguarding against water and moisture. Employing a waterproofing membrane can effectively avert water-related harm to both the plant room and its enclosed equipment. By establishing a protective barrier, the membrane effectively prohibits the infiltration of water into the walls, floors, and ceilings of the plant room. This becomes particularly crucial in regions prone to water leaks or condensation. Waterproofing membranes are meticulously engineered to endure diverse environmental circumstances, guaranteeing enduring protection for plant rooms.

- Q: Can a waterproofing membrane be used in swimming pools?

- Indeed, the utilization of a waterproofing membrane in swimming pools is widespread. To avert water leakage, it is a customary practice to incorporate waterproofing membranes during the construction or refurbishment of swimming pools. These membranes possess an exclusive design that enables them to function as a barrier against water infiltration, guaranteeing the pool's impermeability and leak-free condition. Typically, these membranes are crafted from robust materials like PVC, EPDM, or polyurethane, which exhibit resistance to water, chemicals, and UV rays. Furthermore, their flexibility allows them to effortlessly conform to the pool's shape and contours, providing a seamless and enduring waterproofing solution.

- Q: Can a waterproofing membrane be used in renovation or retrofitting projects?

- Certainly, a waterproofing membrane is a viable option for use in renovation or retrofitting endeavors. In fact, it often plays a crucial role in these projects, guaranteeing the long-term resilience and safeguarding of the building or structure. Waterproofing membranes are specifically designed to establish a barrier against moisture infiltration, effectively thwarting water damage, mold proliferation, and structural decay. When engaging in renovation or retrofitting tasks, it is not uncommon to encounter predicaments such as leaks, cracks, or deteriorated building materials that undermine the building's waterproofing system. In such scenarios, the application of a waterproofing membrane over the affected areas proves to be a reliable method of sealing and protecting them from further harm. This can be accomplished both internally and externally, tailored to the specific requirements at hand. Waterproofing membranes are available in a variety of forms, including sheet membranes, liquid coatings, or spray-applied membranes. They can be employed on various surfaces such as roofs, walls, basements, and even foundations. These membranes possess qualities such as flexibility, durability, and resistance to water and other environmental pressures, rendering them exceptional for renovation or retrofitting undertakings where augmenting the building's waterproofing capabilities is imperative. In conclusion, it is highly advisable to incorporate a waterproofing membrane into renovation or retrofitting ventures to ensure the endurance and integrity of the building. It serves as a proactive measure to preclude future water damage, preserve structural stability, and enhance the overall quality of the revitalized or retrofitted space.

- Q: Can a waterproofing membrane be used in historical or heritage buildings?

- Yes, a waterproofing membrane can be used in historical or heritage buildings. However, it is important to consider the specific requirements and sensitivities of these types of buildings before applying any waterproofing solution. Historical or heritage buildings often have unique architectural features, materials, and construction techniques that need to be preserved and protected. When using a waterproofing membrane in historical or heritage buildings, it is crucial to select a product that is compatible with the existing materials and will not cause any damage or alteration to the structure. It is recommended to consult with a professional architect or preservation expert who has experience working with historical buildings to ensure that the chosen waterproofing membrane is suitable for the specific requirements of the building. Additionally, it is important to consider the aesthetic impact of the waterproofing membrane on the building's appearance. Historical or heritage buildings often have unique architectural details and façades that contribute to their character and value. Therefore, the waterproofing membrane should be chosen carefully to ensure that it does not detract from the building's historical significance or visual appeal. In summary, a waterproofing membrane can be used in historical or heritage buildings, but it should be selected and applied with caution. It is essential to consider the building's materials, construction techniques, and aesthetic value to ensure that the waterproofing solution does not compromise the integrity or historical significance of the structure.

- Q: Can a waterproofing membrane be used for a tunnel waterproofing system?

- Yes, a waterproofing membrane can be used for a tunnel waterproofing system. Waterproofing membranes are commonly used in construction projects to provide a barrier against water infiltration, and they can effectively prevent water from penetrating into tunnels, ensuring their long-term durability and structural integrity.

- Q: Can a waterproofing membrane be used for airport runways?

- Airport runways, when faced with heavy aircraft traffic, weather conditions, and potential fuel spills, undergo significant wear and tear. To combat this, a waterproofing membrane can be utilized. This membrane acts as a protective shield, preventing water infiltration and subsequent runway deterioration. Moreover, it acts as a barrier against fuel, oil, and other chemicals that can weaken the runway structure. By reducing the impact of freeze-thaw cycles and obstructing the formation of cracks and potholes, a waterproofing membrane effectively prolongs the runway's lifespan. Ultimately, incorporating a waterproofing membrane enhances the durability and safety of airport runways, ensuring seamless operations and minimal maintenance expenses.

- Q: Can a waterproofing membrane be used for a shower enclosure?

- Yes, a waterproofing membrane can be used for a shower enclosure. These membranes are specifically designed to prevent water from seeping through the walls and floor, ensuring a watertight seal. They are commonly used in construction and renovation projects to protect areas prone to moisture, such as bathrooms and showers.

Send your message to us

TPO Waterproof Membrane Professional Supplier for Thickness 1.2mm 1.5mm 2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords