TPO Waterproof Membrane for Thickness 1.2mm 1.5mm 2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TPO Waterproof Membrane

1. Introduction

TPO (Thermoplastic Polyolefin) waterproof membrane is typically based on polypropylene and EP (ethylene-propylene) rubber. TPO mainly contains carbon atoms and hydrogen atoms and does not contain any plasticizers and chlorine elements. It is a beautiful, long-lived environment-friendly product. TPO membranes are installed mechanically-attached, fully-adhered or ballasted.

2. Features

l It’s easy to install with good system integrity, few accessories.

l Excellent tensile strength, tearing resistance and penetration resistance performance..

l Hot-air welding. The peel strength of joint is high. Fast welding speed.

l Environment friendly, 100% recycled, without chlorine.

l Durable hot welding performance and easy to repair.

l Smooth surface, no fading and pollution.

3. Specification

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

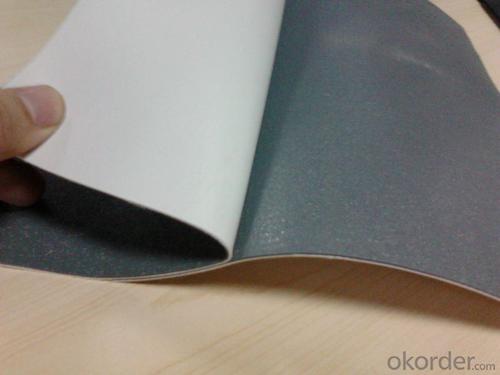

Type | Homogeneous, Internally reinforced with fabric, With fabric backing |

Color | White grey |

4. Applications

l Roof construction & steel structure of both industrial and civil engineering

l Underground engineering, such as subways, tunnels, air Raid shelter, etc.

l Sewage treatment, dam, reservoir and basement, grain storehouse, etc.

5. Classification

H- Homogeneous TPO membrane

L- TPO membrane with fabric backing

P- TPO membrane internally reinforced with fabric

6. Technical Data Sheet

TPO Waterproof Membrane | Standard: GB27789-2011 | |||||||

NO. | Item | Unit | Value | |||||

H | L | P | ||||||

1 | Resin Thickness on Middle Mesh ≥ | mm | - | - | 0.4 | |||

2 | Tensile Properties | Max. Strength ≥ | N/cm | - | 200 | 250 | ||

Tensile Strength ≥ | Mpa | 12.0 | - | - | ||||

Elongation at Max. Strength ≥ | - | - | 15 | |||||

% | 500 | 250 | - | |||||

3 | Dimensional Stability after Heat Treatment ≤ | % | 2.0 | 1.0 | 0.5 | |||

4 | Foldability at Low Temperature | -40℃ No cracks | ||||||

5 | Watertightness | 0.3Mpa, 2h No penetration | ||||||

6 | Resistance to Impact | 0.5kg*m, No penetration | ||||||

7 | Resistance to Static Loading | - | - | 20kgs No penetration | ||||

8 | Joint Peel Strength≥ | N/mm | 4.0 or membrane broken | 3.0 | ||||

9 | Right Angle Tearing Strength≥ | N/mm | 60 | - | - | |||

10 | N/mm | - | 250 | 450 | ||||

11 | Water Absorption (70℃, 168h) ≤ | % | 4.0 | 3.0 | ||||

12 | Aging in Hot Weather (115℃) | Time | 672h | |||||

Appearance | No bubbles, cracks, layering, sticky, hole | |||||||

Max. Tensile Retention Rate ≥ | % | - | 90 | |||||

Tensile Strength Retention Rate ≥ | % | 90 | - | - | ||||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 90 | ||||

Breaking elongation Retention rate | % | 90 | 90 | - | ||||

Low Temperature Flexibility | -40℃ No cracks | |||||||

13 | Chemical resistance

| Appearance | No bubbles, cracks, layering, sticky, hole | |||||

Max. Tensile Retention Rate ≥ | % | - | 90 | 90 | ||||

Tensile Strength Retention Rate ≥ | % | 90 | - | - | ||||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 90 | ||||

Breaking elongation Retention rate | % | 90 | 90 | - | ||||

Low Temperature Flexibility | -40℃ No cracks | |||||||

14 | Artificial aging | Time | 1500h | |||||

Appearance | No bubbles, cracks, layering, sticky, hole | |||||||

Max. Tensile Retention Rate ≥ | % | - | 90 | 90 | ||||

Tensile Strength Retention Rate ≥ | % | 90 | - | - | ||||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 90 | ||||

Breaking elongation Retention rate | % | 90 | 90 | - | ||||

Low Temperature Flexibility | -40℃ No cracks | |||||||

Remarks: l Resistance to static load is for TPO membranes used on roofing l The time of artificial aging of single-ply roofing membrane is 2500h. | ||||||||

Images of EPDM Rubber Waterproof Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used on roofs with skylights?

- Certainly, roofs with skylights can benefit from the use of a waterproofing membrane. It is strongly advised to employ a waterproofing membrane around skylights in order to prevent water infiltration or leakage. Skylights have the potential to become weak points in a roof system, as they form openings that can let water seep through if not adequately sealed. The application of a waterproofing membrane around the skylights serves to establish a watertight barrier that safeguards the roof from any potential leaks. Furthermore, a waterproofing membrane also offers added protection against external factors such as UV rays and changes in temperature, thereby extending the lifespan of both the skylights and the roof itself.

- Q: Can a waterproofing membrane be used for stadiums or arenas?

- Certainly, stadiums and arenas can absolutely benefit from the utilization of waterproofing membranes. In fact, it is highly advisable to employ these membranes in these expansive constructions to shield them from water harm and leaks. These grand structures are frequently subjected to diverse weather conditions, including substantial rainfall and snowfall, which have the potential to infiltrate the edifice with water. A waterproofing membrane functions as a barricade, impeding water from entering the building and causing harm to its structural elements, such as concrete or steel. It aids in upholding the structure's integrity and protracting its lifespan. Moreover, waterproofing membranes also offer protection against other forms of moisture, such as condensation and humidity, which can result in mold growth and materials deterioration. Therefore, the application of a waterproofing membrane is an essential measure in guaranteeing the endurance and longevity of stadiums and arenas.

- Q: Can a waterproofing membrane be used in conjunction with insulation materials?

- Using both insulation materials and a waterproofing membrane together is often recommended in order to protect buildings from moisture and improve energy efficiency. The waterproofing membrane acts as a barrier against water infiltration, while the insulation materials help regulate temperature and minimize heat loss or gain. By combining these components, the building envelope can effectively shield against water damage and maintain a comfortable indoor environment. Proper installation and compatibility between the waterproofing membrane and insulation materials are crucial for achieving optimal performance and long-lasting results.

- Q: Are waterproofing membranes resistant to chemicals?

- Waterproofing membranes are generally resistant to chemicals, providing a protective barrier against water infiltration. These membranes are typically made from materials like PVC, TPO, or EPDM, which possess excellent chemical resistance properties. Their engineering ensures they can endure exposure to various chemicals like acids, alkalis, solvents, and oils without deteriorating. This chemical resistance guarantees that waterproofing membranes can maintain their integrity and effectiveness even in environments with common chemical exposure, such as industrial settings, laboratories, or chemical storage areas. However, it is important to consider that the specific chemical resistance capabilities may differ based on the type and quality of the chosen waterproofing membrane. Therefore, it is crucial to select the appropriate membrane that matches the project's specific chemical exposure requirements.

- Q: Is a waterproofing membrane resistant to chemicals?

- Typically, a waterproofing membrane resists chemicals. Its purpose is to create a protective barrier against water, liquids, and chemicals. The materials used to make these membranes, such as PVC, TPO, and EPDM, are chemically resistant. They have excellent resistance to a variety of chemicals, including acids, alkalis, solvents, and oils. Furthermore, rigorous testing is conducted on waterproofing membranes to ensure their durability and chemical resistance. However, it is important to consider that the membrane's resistance to specific chemicals may vary based on its type and quality. To ensure compatibility with certain chemicals, it is always advised to refer to the manufacturer's specifications and guidelines.

- Q: Can a waterproofing membrane be used in areas with high foot traffic or heavy loads?

- Yes, a waterproofing membrane can be used in areas with high foot traffic or heavy loads. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can withstand various types of stress, including foot traffic and heavy loads. However, it is important to choose a waterproofing membrane that is specifically designed for these conditions. There are different types of membranes available, each with varying levels of durability and strength. It is crucial to consult with a professional waterproofing expert or manufacturer to ensure that the chosen membrane is suitable for the specific requirements of the area with high foot traffic or heavy loads. Proper installation and maintenance of the membrane are also essential for its long-term effectiveness in these conditions.

- Q: Can a waterproofing membrane be used in high-rise buildings?

- High-rise buildings can benefit from the use of a waterproofing membrane. Incorporating a waterproofing system is highly recommended to safeguard these structures from the harmful consequences of water infiltration. Waterproofing membranes serve as a protective barrier, effectively preventing leaks and moisture damage to the building. They are commonly applied on roofs, basements, foundations, and other areas exposed to water or moisture. The choice of the appropriate waterproofing membrane relies on several factors, including the building's specific design, construction materials, and environmental conditions. It is crucial to seek advice from experienced waterproofing professionals to identify the most suitable membrane system for long-term protection against water-related problems in high-rise buildings.

- Q: Can waterproofing membranes be used on stormwater management systems?

- Indeed, stormwater management systems can benefit from the application of waterproofing membranes. These membranes are frequently utilized to safeguard structures against water infiltration and potential water-related harm. In the case of stormwater management systems, which are designed to collect, retain, and efficiently handle rainwater runoff, waterproofing membranes can be employed to establish a completely watertight seal, thereby averting leaks and seepage. Stormwater management systems often incorporate various components, such as retention ponds, infiltration basins, or underground storage systems. These elements must be adequately sealed to ensure the proper containment and effective management of the collected stormwater. When properly installed, waterproofing membranes serve as an impermeable barrier, effectively preventing water from escaping or infiltrating the system. The utilization of waterproofing membranes on stormwater management systems offers numerous advantages. Firstly, it helps to maintain the system's integrity and functionality by preventing leaks or seepage that could compromise its performance. This ensures that the stormwater is efficiently captured and managed, minimizing the risk of flooding or erosion. Furthermore, waterproofing membranes can significantly prolong the lifespan of stormwater management systems by safeguarding them against water damage. Water infiltration can lead to structural degradation, corrosion, or the proliferation of mold and mildew, all of which weaken the system over time. By establishing a waterproof barrier, these membranes contribute to the preservation of the structural integrity of the components, thus increasing their longevity and reducing maintenance requirements. Moreover, the use of waterproofing membranes on stormwater management systems also contributes to environmental sustainability. By effectively containing and managing stormwater runoff, these systems aid in reducing water pollution and enhancing the quality of natural water bodies. Waterproofing membranes play a vital role in preventing stormwater from carrying pollutants, such as chemicals or sediment, into rivers, lakes, or oceans. In conclusion, waterproofing membranes can be effectively utilized on stormwater management systems to establish a watertight seal, prevent leaks, and protect the components from water damage. By providing an impermeable barrier, these membranes help to maintain the system's functionality and integrity, prolong its lifespan, and contribute to environmental sustainability by reducing water pollution.

- Q: How does a waterproofing membrane handle water vapor transmission?

- A waterproofing membrane handles water vapor transmission by preventing the passage of water vapor through its surface. It acts as a barrier to prevent moisture from penetrating the membrane, thus protecting the underlying structure from potential damage caused by moisture.

- Q: Can a waterproofing membrane be used on tunnels?

- Yes, a waterproofing membrane can be used on tunnels. Waterproofing membranes are commonly used in tunnel construction to prevent the ingress of water and protect the structure from potential water damage. These membranes are designed to be highly durable, flexible, and resistant to external factors such as water pressure and ground movements. They provide a reliable barrier against water infiltration, helping to maintain the structural integrity of the tunnel and ensure its long-term functionality.

Send your message to us

TPO Waterproof Membrane for Thickness 1.2mm 1.5mm 2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords