Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | nude packing or wooden case packing as your request |

| Delivery Detail: | 30 days after receipt 30%T/T as deposite |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

This machine set is to satisfy the customer’s requirements of high quality, high output film blowing equipment.

It adopts the extruder with force feeding function, precision type ceramic heater, precision type double vents air ring, horizontal type rotary traction system, fully automatic surface friction type double cut double winders, computer concentrate control system.

Advanced technique and equipments, compare with kindred equipment, it has the advantages such as more compact structure, high output, better produce quality, less energy consume, easier operation.

It can be widely used into various kind of high transparence packing film manufacture and create the considerable economic benefit for you.

Fully automatic double cut double winders

Optional parts:

Auto loaderX3pcs

Chiller

Corona

Full automatic winder

Embossing roller

collecting material drop

Technical data:

Model | MD-3L50 | MD-3L55 | MD-3L65 |

Suitable Material | LDPE LLDPE EVA HDPE | ||

Max Film Width(mm) | 1200 | 1500 | 2000 |

Film Thickness(mm) | LD:0.015-0.15 | ||

Max Extrusion Output LD | 140kg/hr | 200kg/hr | 280kg/hr |

Extrusion unit | |||

Gear Box | 146/173/146 | 173/200/173 | 200×3 |

Screw Diameter(mm) | φ50/55/50 | φ55/65/55 | φ65/65/65 |

Screw L/D Ratio | 28:1 | ||

Screw’s Material | 38 CRMOALA | ||

Barrel’s Material | 38 CRMOALA | ||

Barrel’s Cooling Fan | 370W×2×3 | 370W×2×3 | 370×3×3 |

Thermo Control (zone) | 3×3 | 3×3 | 4×3 |

Driving Motor (kw) | 15/22/15 | 22/30/22 | 30/30/30 |

Extrusion Die | |||

Die Size (mm) | LD:φ250/300 | LD:φ350/400 | LD:φ500 |

Rotary Die Head (mm) | 360°Continue Rotary | ||

Screen Changer | Manual Mechanics Screen Changer | ||

Thermo Control (zone) | 3 | 4 | 4 |

Air Ring | 1 PCS | ||

Cooling Blower (kw) | 5.5 | 7.5 | 11 |

Take-UP Unit | |||

Roller Width (mm) | φ165×1300 | φ165×1600 | φ190×2100 |

Take-UP Motor (kw) | 1.5 | 1.5 | 2.2 |

Take-UP Speed(M/min) | 5-60 | 5-60 | 5-60 |

Winding Unit | |||

Type OF Winder | Surface Friction Double Winder | ||

Roller Width (mm) | 1300 | 1600 | 2100 |

Winding Motor | 16N.M | 1.5kw | 1.5kw |

Winding Speed(M/min) | 5-60 | 5-60 | 5-60 |

Voltage | 380V, 50HZ, 3PHASE | ||

Cover Dimensions (m) | 6.8×2.6×6.5 | 7.5×3.2×7.5 | 9×4.2×9 |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

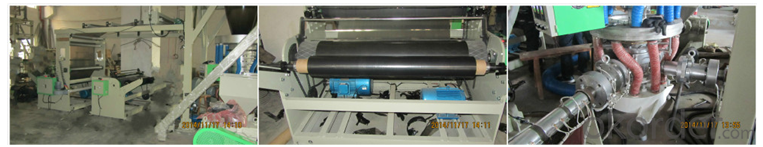

Machine at factory,double winder,simple type

Our other hot-sale machine(click the picture to know more information)

Company show

- Q: What cloth is the filter cloth used to filter oil? Where can I buy it?

- The filter cloth used in the oil press used in the oil press can be either linen or cotton.

- Q: How often is the filter element of the turbine oil vacuum oil filter changed?

- 2, filter replacement frequency and filter quality, pollutant carrying capacity and impurity content in turbine oil situation, as well as the frequency of ink through the printer, if you usually print, ink consumption certainly too much, of course, if the printer design quality problems, there is leaking ink, then ink consumption is fast.3, in order to reduce zjc filter supplies cost, can choose to consider the following ideas.[1] add a frame filter oil machine filter through the vast majority of impurities, after filtering particles, filter and vacuum oil filter, it can make more clean oil into the vacuum oil filter, filter to reduce the blocking probability; [2] the cleaning filter, but generally the last precision filter filtration precision, the general can not be used in cleaning filter. [3] procurement of better quality, sewage capacity stronger filter.

- Q: Where can I get a good oil filter?

- 1, to buy oil filter must first understand what is the oil filter, what is the function and effect, and the relevant background knowledge, and then query or search for information about the current oil industry some leading enterprises such as what company. Only roughly know clearly that we can roughly grasp the manufacturers of oil filter oil filter, power price, otherwise it is smoke and mirrors, puzzled, what is what others say. Especially in the current oil filter industry, the majority of small and medium enterprises, this kind of supporting industries, but also be careful. Non-standard small industry, the water is very deep, disorganized, disorderly development, it is easy to sell shoddy products.2 、 oil filter is an auxiliary type of non-standard machinery, mainly used for industrial oil or cooking oil, here mainly on industrial oil filter. Many kinds of industrial oil, most of the functions are lubrication, reduce friction and temperature, antifreeze, anti rust, insulation, hydraulic, widely used in industry, various applications, therefore, the industry developed oil filter oil filter the corresponding machine according to different application scenarios, convenient for users to choose. The oil filter from the technical angle, mainly vacuum oil filter, filter bag, trolley type oil filter oil filter, oil filter, pressure plate type centrifugal oil filter, electrostatic oil filter, ceramic filter and so on, in front of several popular on the market, after several major for special industries, cost high, most users can not touch on.

- Q: Excuse me, what's the reason why the oil is not clear and cloudy after being filtered by the centrifugal oil filter?

- [2] in the presence of oil colored substances dissolved in oil, the centrifugal oil filter that can only choose incapable of action, decolorization, if industrial oil can adsorb colored substances through clay, activated carbon and other substances, or by chemical reaction, but the technology is complex.

- Q: Transformer oil filter how to choose?

- Our company is also transformer oil inlet, according to our oil situation, the choice is a two stage transformer oil vacuum oil filter, after use, there is a great improvement

- Q: Classification of oil filters According to the principle of the oil filter

- Viscosity of oilHigh viscosity oil can not pass through fine screen, so it is necessary to reduce the accuracy. Because: (1) filter often plug, need frequent cleaning, or even replace the filter.(2) the increase of the axial pressure, the oil can quickly pass filter, but tend to crush the filter.(3) adding preheated fuel tank to increase temperature and reduce viscosity.Generally speaking, the filtration precision of the fine filtration stage is chosen as:(1) insulating oil, choose 1~5 mu m.(2) lube oil and turbine oil under 46, select 10~20 mu m.(3) internal combustion engine oil and gear oil are chosen 20~50 mu m.

- Q: Can hydraulic oil filters change color after filtration?

- Can only become shallow, because part of the color is suspended particles, impurities caused by some of the high temperature oxidation, chemical properties change, filtration is physical, how can I do?!

- Q: Which is the best vacuum oil filter?

- Selection of good oil filter manufacturers, if the budget is abundant, must be good brand, good quality, good after-sales company to buy, although the high prices, but with ease, little problems. If the budget is not enough, then you need to compare by Baidu search or other platforms. Compare your company's size, technical level, quality, after-sale reputation, user success stories, etc., and combine your budget options

- Q: How many kinds of transformer oil vacuum oil filters are available?

- Sum up, as long as you know what the oil is, know the amount of oil, want to achieve what effect, you can find the right transformer oil, vacuum oil filter, hoping to help you, hope to adopt

- Q: How often does the oil filter in the turbine run oil filter change? Thank you for

- This is not fixed. Look at the color of the filter paper. You can see the filter paper is dirty and yellow, so you can change it.

Send your message to us

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords