Three And Five Layers Co-Extrusion Film Blowing Machine Set (IBC), Extruder, Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | nude packing or wooden case packing as your request |

| Delivery Detail: | 30 days after receipt 30%T/T as deposite |

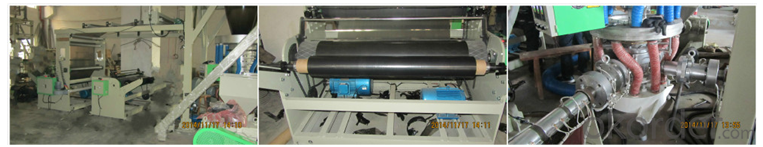

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

This machine set is to satisfy the customer’s requirements of high quality, high output film blowing equipment.

It adopts the extruder with force feeding function, precision type ceramic heater, precision type double vents air ring, horizontal type rotary traction system, fully automatic surface friction type double cut double winders, computer concentrate control system.

Advanced technique and equipments, compare with kindred equipment, it has the advantages such as more compact structure, high output, better produce quality, less energy consume, easier operation.

It can be widely used into various kind of high transparence packing film manufacture and create the considerable economic benefit for you.

Fully automatic double cut double winders

Optional parts:

Auto loaderX3pcs

Chiller

Corona

Full automatic winder

Embossing roller

collecting material drop

Technical data:

Model | MD-3L50 | MD-3L55 | MD-3L65 |

Suitable Material | LDPE LLDPE EVA HDPE | ||

Max Film Width(mm) | 1200 | 1500 | 2000 |

Film Thickness(mm) | LD:0.015-0.15 | ||

Max Extrusion Output LD | 140kg/hr | 200kg/hr | 280kg/hr |

Extrusion unit | |||

Gear Box | 146/173/146 | 173/200/173 | 200×3 |

Screw Diameter(mm) | φ50/55/50 | φ55/65/55 | φ65/65/65 |

Screw L/D Ratio | 28:1 | ||

Screw’s Material | 38 CRMOALA | ||

Barrel’s Material | 38 CRMOALA | ||

Barrel’s Cooling Fan | 370W×2×3 | 370W×2×3 | 370×3×3 |

Thermo Control (zone) | 3×3 | 3×3 | 4×3 |

Driving Motor (kw) | 15/22/15 | 22/30/22 | 30/30/30 |

Extrusion Die | |||

Die Size (mm) | LD:φ250/300 | LD:φ350/400 | LD:φ500 |

Rotary Die Head (mm) | 360°Continue Rotary | ||

Screen Changer | Manual Mechanics Screen Changer | ||

Thermo Control (zone) | 3 | 4 | 4 |

Air Ring | 1 PCS | ||

Cooling Blower (kw) | 5.5 | 7.5 | 11 |

Take-UP Unit | |||

Roller Width (mm) | φ165×1300 | φ165×1600 | φ190×2100 |

Take-UP Motor (kw) | 1.5 | 1.5 | 2.2 |

Take-UP Speed(M/min) | 5-60 | 5-60 | 5-60 |

Winding Unit | |||

Type OF Winder | Surface Friction Double Winder | ||

Roller Width (mm) | 1300 | 1600 | 2100 |

Winding Motor | 16N.M | 1.5kw | 1.5kw |

Winding Speed(M/min) | 5-60 | 5-60 | 5-60 |

Voltage | 380V, 50HZ, 3PHASE | ||

Cover Dimensions (m) | 6.8×2.6×6.5 | 7.5×3.2×7.5 | 9×4.2×9 |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

Machine at factory,double winder,simple type

Our other hot-sale machine(click the picture to know more information)

Company show

- Q: How often is the filter element of the transformer oil vacuum oil filter changed?

- How long is the filter element of the transformer oil vacuum filter? There is no definite time

- Q: What parameters should be provided for purchasing turbine oil filters?

- First, to see whether you need to filter the water and gas, if necessary, in general to choose the special vacuum oil turbine oil filter, such as the TYAXD series; if these particles can filter impurities, portable LY or LY plate oil filter can, by the way,

- Q: Why does the centrifugal oil filter filter out peanut oil? Why does it stink?

- Pour the washed wool oil evenly into the rotary drum

- Q: How often is the filter element of the turbine oil vacuum oil filter changed?

- 1, this depends on your own oil content of impurities, as well as vacuum filter oil filter itself quality and function. For example, your higher oil turbine impurity content, so it is easy to clog the filter clogging, need to clean or replace (note that some of the filter can be cleaned, and some can not be bought, when the oil filter need to ask, and generally can clean the filter than cleaning the filter element to the high price); and if the purchase of oil filter machine as well as filter quality, low intensity, filtering accuracy is not good, the assimilative capacity is small, the filter is easy to jam.

- Q: Why is the oil filtered out of the oil filter cleaner?

- Also depends on the oil pollution, as well as the oil filter machine design and work, oil dirty need more cycle, filter several times

- Q: Plate and frame filter press VS centrifugal oil machine competition, who is better?

- As a medium of paper or cloth lining plate oil filter filter plate and the filter frame, with the pressure of the pressing device to filter plate and the filter frame fixed to form a separate filter chamber, tightly pressed between the filter plate and the filter frame of the paper or cloth filtration effect

- Q: How to select flow rate for turbine oil vacuum oil filter?

- Yes, turbine oil is also called turbine oil, so the turbine oil vacuum oil filter is actually a turbine oil vacuum oil filter

- Q: Fig. 1 electrical control diagram of lubricating oil vacuum oil filter lv_80

- Besides the general bought oil filter, as long as the regular manufacturers will have the instructions, the above detailed parameters of oil filter, and the electrical principle diagram and electrical control chart, do you buy the oil filter machine instructions are not even,. If so, either you choose to return it, or you call the person who sold it to you, and let them come home to deal with the problem, which is the minimum after-sales service.

- Q: Main parameters of ZYA-50 vacuum oil filter

- Use:Widely used in various types of power equipment insulation oil purification treatment. Especially for high grade new oil, imported oil and ultra high pressure transformer oil. The utility model can be used for live operation in substations above 110KV, and is especially suitable for the areas with higher elevation. The utility model can be used as drying equipment for drying steam equipment of a power plant, and can completely replace vacuum oiling machine to carry out vacuum oiling to electric equipment. It can also be used as an efficient purification equipment for other low viscosity lubricating oils.

- Q: How does the 25 litre oil purifier determine flow?

- The parameters to be considered: 1. filter oil flow (this is the most important, according to your company's oil situation to determine the appropriate flow of oil filter,

Send your message to us

Three And Five Layers Co-Extrusion Film Blowing Machine Set (IBC), Extruder, Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords