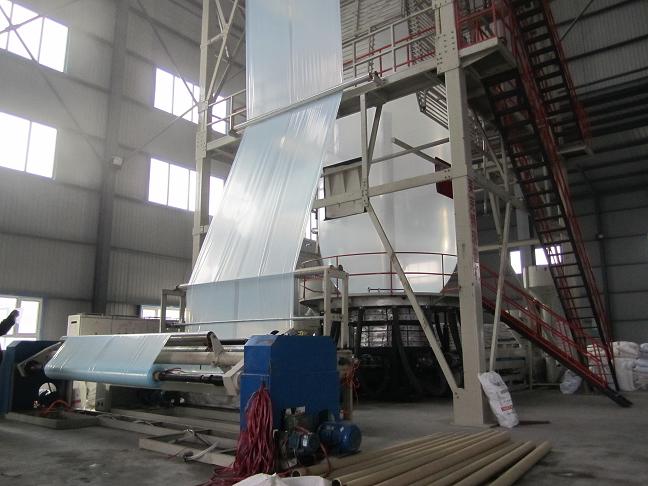

HDPE LDPE Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

This film blowing machine is suitable for blowing the plastic film as high density Polyethylene (HDPE), low density Polyethylene (LDPE) and linear low density Polyethylene (LLDPE), which is widely used for packing foodstuff, garment, textile, daily-use articles and industrial products etc. It can produce pearl film and degradation film via making up a prescription. This kind of machine is the widest use in the market at present and it's the preferred machine for building a film-blowing factory.

Characteristic:

1. The screw and cylinder are made of 38CrMoAl high quality alloy steel after fine finishing and nitrided treatment, which has high hsrdness, srrong resistance to corrosion, durable service.

2. The die head is plated with hard chrome, of screw mandrel type structure with even and smooth discharging, the blown plastic film has fine finishing; The blower is of labyrinth structure with even air output.

3. The coiling unit adopts pressure friction rewinding or center rewinding, which is driven by torque motor, with even and smooth rewinding and easy roll changing.

Technical Parameters:

| Type | 45 | 50 | 55 | 60 | 70 | 80 | 85 | 90 | 110 | 110-2 | |

| Diameter of Screw(mm) | Φ45 | Φ50 | Φ55 | Φ60 | Φ70 | Φ80 | Φ85 | Φ90 | Φ110 | Φ110 | |

| L/D ration of screw | 30:1 | ||||||||||

| Specification of Die Head | Φ40 -100 | Φ60 -130 | Φ70 -160 | Φ90 -200 | Φ110 -250 | Φ200 -300 350 | Φ200 -350 | Φ400 -500 | Φ400 -600 | Φ400 -900 | |

| Thickness of Products(mm) | 0.004-0.08/0.025-0.15 | ||||||||||

| Folding width of Products(mm) | 100 -600 | 100- 800 | 100- 1100 | 100- 1200 | 200- 1500 | 200- 1600 | 200- 1800 | 200- 2000 | 200- 2500 | 200- 4000 | |

| Main power(kw) | 12 | 18 | 22 | 22 | 22 | 30-37 | 37-45 | 37-45 | 55-75 | 75× 2 | |

| Max. Output(kg/h) | 30 | 35 | 50 | 60 | 80 | 70-100 | 100-130 | 180 | 280 | 450 | |

| Weight(T) | ≈1.6 | ≈1.8 | ≈2.0 | ≈2.2 | ≈4 | ≈4.5 | ≈5 | ≈6 | ≈6.5 | ≈8 | |

| Overall Dimensions(L× W×H) )(m ) | 3.6× 1.5 × 3.5 | 4×1.9×3.8 | 4.1×2×4.3 | 4.2×2.2×4.5 | 5× 2.7× 5.5 | 5.3× 2.9× 6 | 6× 3.1 × 7 | 7× 3.3× 7.5 | 8× 3.8 × 9 | 9× 3.5× 15 | |

- Q: Points for attention of vacuum oil filter

- Application and notice of vacuum oil filter2.1 because the vacuum oil filter is used less (one or two years only last time), therefore, the operator should read the instruction carefully before operation, and must be familiar with the operation method of the oil filter.2.2 operate strictly according to the order of instructions and strictly control the oil level of the tank to prevent the oil from being absorbed into the vacuum pump.2.3, the oil temperature is generally controlled at 40~60 degrees (except for instructions).2.4, the use of oil filters are often checked, the oil pipe joints, valves are blocked, oil spills, such as the breakdown should immediately stop inspection, processing. Anti static earthing measures shall be adopted for the oil filter and the metal piping of the oil system.2.5 during the operation of the vacuum oil filter, when the outlet oil pressure is greater than 0.3Mpa, the reasons should be checked. When the plug is stopped, the filter components can be stopped, cleaned or replaced.2.6, operators must be strictly responsible for the work, serious and responsible, on duty, shall not do other irrelevant things.

- Q: What cloth is the filter cloth used to filter oil? Where can I buy it?

- The aperture is big is small, a larger aperture, less oil filter mesh, the faster the speed, the effect will be worse;

- Q: What's good for lubricating oil dehydrating and oil filters?

- Many brands on the market, imported USA PALL, his things are very expensive, especially in the late supplies, if you have the factory money can consider. Haddok seems not bad

- Q: Portable continuous refining machines and pneumatic oil filters that good

- First of all: you hit the wrong character, no portable oil refining machine, oil machine is also true of petrochemical enterprises will have less, while more than hundreds of thousands, millions, and refining facilities generally large, covers a wide area, how likely is portable, so you should be a portable oil filtering machine.

- Q: Pneumatic oil filter is slow, isn't it too low?

- The vacuum oil filter can filter water, and can also filter impurities, in which the function of filtering impurities is achieved by strong magnetic adsorption and filter blocking,

- Q: Why does the vacuum oil filter tank foam?

- 1: the fuel tank return port is improperly set, resulting in two gas mixing. Generally, the condensate gas tank, precipitation, slag falling settlement, oil return port is arranged below the surface of oil, the oil from the high drop into the tank, increase the chance of air into the oil, also caused a stir, let the water back by gravity sedimentation oil layer, bubble generation.2: steam turbine system design flaws or system aging and other man-made EH steam turbine oil system with steam or water, then will cause the oil emulsion, oil emulsion into the vacuum distillation tower, high temperature vacuum evaporation, bubble, if EH oil vacuum filter without defoaming or eliminating system bubble device damage will lead to the bubble with the oil into the tank to cycle.

- Q: How often do you change the oil filter when the turbine is in oil?

- When the new oil content is high, the filter paper will be changed in 1 hours. Are you using a plate type oil filter? We use, steam turbine lubricating oil system filter within 24 hours will alarm, indicating that the filter will filter scraps of paper jam, the actual collapse filters also illustrate this point, now the oil filter machine in our system has no.

- Q: The vane filter and the centrifugal oil filter are good

- Choose which specific, you need to see what materials you deal with, what you want to achieve

- Q: I am pressed sunflower oil, vacuum phase electric heating oil filter, oil filter to the end why there is a place

- After falling down, when the impact force is reached, the oil and air mix to produce bubbles.The oil is relatively viscous, falling down, blocked by oil drums and oil, and mixing with the air to produce bubbles.

- Q: The difference between plate type oil filter and automatic slag filter

- Plate type oil filter investment is relatively small, but the latter supplies high cost, the scene is dirty, oil consumption is higher, labor costs relative to more than one person's expenses.

Send your message to us

HDPE LDPE Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords