Automatic Extrusion Blowing Machine for LED Light PC Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Extrusion Blowing Machine for LED Light PC Cap

LED Light PC Cap Automatic Extrusion Blowing Machine Production Line Feature:

Reasonable equipment design, compact construction, simple operation

Equipment with high degree automatic, cost less expenses

Electrical equipment, Hydraulic system, Seal parts and Lubrication system adopt the components of famous factory in the world, with low failure rate.

To achieve the best quality guarantee, no matter the appearance and internal, automatic extrusion blowing machine rate of quality goods is above 99%.

LED Light PC Cap Automatic Extrusion Blowing Machine Technical Characteristic:

LED Light PC Cap Automatic Extrusion Blowing Machine adopt European technology, control the hydraulic system with pressure and flow double proportion. The speed of pressure can adjust nonpolarly, high stability, exchange control the electrical system with man-machine interface. Operating surface has a machinery safety configuration, two electrical safety configuration to ensure the safety of operators.

PLC+touch screen, making the operation easy. Automatic malfunction alarm with selfdiagnosis, making the malfunction clear at a glance.

Center input die head, eliminating the knit line completely and making it easy to change the material and color.

Double linear rolling motion guider in moving, opening and closing mold, making the clamping force equally distributed, so the cut is smoother.

Control the hydraulic system with imported proportional valve, ensuring the action steady, accurate and energy saving.

High speed and efficient plasticizing system, mixing well and ensuring the produce purity.

LED Light PC Cap Automatic Extrusion Blowing Machine Parameter:

Specifications | Unit | Parameters |

Max container capacity | L | 20 |

Extruder System |

|

|

Screw Diameter | mm | 82 |

Screw L/D ratio | L/D | 30:1 |

Screw Speed | rev. / min. | 10~50 |

Plasticizing Capacity | Seconds/die. | 60 |

Number of heating zone barrel | zone | 5 |

Extruder driving Power of barrel | KW | 34 |

Max Injection quantity | L | 1.5 |

Die Head |

|

|

Max die diameter | mm | 130 |

Number of heating zone | zone | 4 |

Extruder driving power | KW | 8.7 |

Clamping Device |

|

|

Platen Size(WxH) | mm | 440 x 600 |

Platen opening stroke | mm | 330~780 |

Clamping force | KN | 210 |

Next blowing Device |

|

|

Blowing the head off and landing trip | mm | 120 |

Manual control Blowing the head off and landing trip | mm | 80 |

Manipulator |

|

|

Take pieces of travel | mm | 1000 |

Framework |

|

|

Lift travel | mm | 250 |

Hydraulic System |

|

|

Rated pressure of big pump | Mpa | 14 |

Rated flow of big pump | L/min | 180 |

Motor power of Hydraulic pumps | KW | 45 |

Parison Controlling Of Hydraulic Servo System |

|

|

Rated pressure | Mpa | 6 |

Rated Flow | L/min | 22 |

Motor power of Hydraulic pumps | KW | 4 |

Pneumatical System |

|

|

Air source pressure | Mpa | 1 |

Working pressure | Mpa | 0.8 |

Air consumption | M3 / min. | 0.6 |

Electrical Control System |

|

|

Water Supply |

|

|

Water supply pressure | Mpa | 0.3 |

Power Supply | ||

Voltage | V | AC380V±10% |

Frequency | HZ | 50 |

Wire |

| 3Phase |

Total of rated power | KW | 91.7 |

Average power consumption | KW.h | 45 |

Total weight | Ton | 11 |

Dimension of machine (Lx W x H) | m | 5.3×2.7×4.5 |

LED Light PC Cap Automatic Extrusion Blowing Machine Parts Picture:

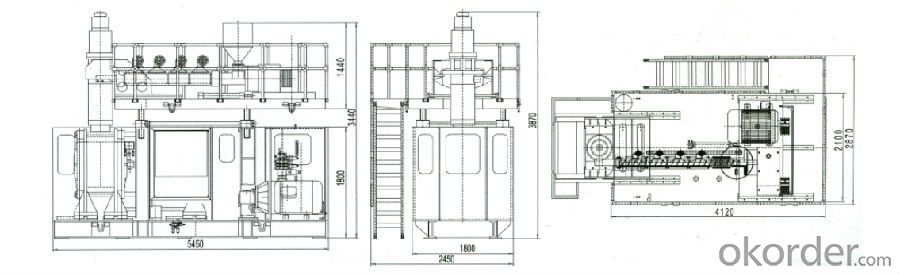

LED Light PC Cap Automatic Extrusion Blowing Machine Drawing Picture:

LED Light PC Cap Automatic Extrusion Blowing Machine Electrical Parts Photo:

LED Light PC Cap Automatic Extrusion Blowing Machine Products Photo:

- Q: What is the working principle of the vacuum oil filter?It's easy to understand

- In the filter to filter out large particles of impurities in oil, but can not filter out the compound emulsion regeneration and oxide molecular structure, often need to pay attention to clean the filter in the process of using, easily broken or blocked.

- Q: How does the oil filter usually be repaired and maintained?

- Then place it where it is not easy to damp and dry. As for the maintenance of oil filters, specific conditions should be analyzed and treated.

- Q: Peanut oil centrifugal filter and vacuum oil filter which is good?

- Research from the user perspective, centrifugal oil production machine is through the drum of high-speed rotation of the centrifugal force generated by the oil fine filter, need water treatment in oil dregs to absorb water becomes heavier, water quality after the diesel oil, the lightest, slag, water, oil natural three layer is formed on the inner wall of the drum rotating at high speed the. When to stop spinning oil bean out of the drum in the micro water surface, to attain the purpose of filtering, the filtered oil pure and clear, can be directly sold in cans or food. The centrifugal oil filter oil machine is the use of the high speed rotating from heart, the degree of pollution of lubricating oil of different oil, water and impurities by the effect of different centrifugal force and rapid separation. Production can be filtered 60-80 Jin each different

- Q: Use vacuum oil filters to filter transformer oil in summer and winter temperature should be in the degree of the northern region

- The relationship between summer and winter temperature filtration is the northern winter temperature, processing filter with manual heating, starting on the line, at the same time on the flow rate, flow velocity and heating speed, the relationship between area, and the filtering area, and the relationship between the impurity and the vacuum tank area, evaporation area, pumping speed, pumping the relationship between the speed and the cooling system of the relationship, and the relationship between the oil pump and so on can't say more, about the product design problem, please forgive!

- Q: What are the 3 basic requirements of hydraulic system for hydraulic oil filters?

- The two is to look at the oil situation, to choose whether to filter impurities, or choose to filter water, but also to filter impurities

- Q: What is the advantage of a centrifugal oil filter?

- Centrifugal oil filter is the use of its high-speed rotation from the heart, so that different levels of contamination of lubricating oil, water, water and impurities by different centrifugal force and the rapid separation. Centrifugal oil filter for power plants, ships, large machinery and equipment lubricating oil, heavy diesel oil and Edible Rapeseed oil, tea oil, peanut oil purification.

- Q: What's the difference between a heated plate and frame oil filter and an ordinary plate and frame oil filter?

- Ordinary plate oil filter is composed of filter bed, pump motor and coarse filter element, filter bed is composed of multi level filter plate and the filter frame, filter paper or cloth lining the filter plate and the filter frame, with pressure filter pressing device, the filter chamber is fixed independently formed between the plate and the filter frame is pressed in between the filter plate and the filter frame of the paper or cloth to play the role of filtering. The heating plate oil filter is independent heating device based on general frame increase oil filter, to filter high viscosity oil, oil filter plate ordinary machine is not filtered for high viscosity oil.

- Q: My vacuum oil filter doesn't filter. Consult an expert

- Vacuum oil filter can not work properly, you should first think of is the direct dial phone manufacturers, the company let oil filter arranged professional and technical personnel on-site to solve, which is the least of the customer service service, but at least you as a consumer rights.

- Q: Which is more advantageous than a centrifugal oil filter and a vacuum oil filter?

- The accuracy of the filter is improved to a certain extent, and the new type of centrifuge has better rotation mode and transmission speed and higher centrifugal rate, so the filtering effect is also improved, and the filtering effect is improved in general.

- Q: Which is the best vacuum oil filter?

- Vacuum oil filter machine imported brands and domestic brands of domestic brands, but also imported and domestic configuration configuration; imported oil filter oil filter better than domestic, domestic and imported configuration than the domestic configuration, the price must be configured expensive. In addition, the vacuum oil purifier has to distinguish the two-stage vacuum oil filter and the single-stage vacuum oil filter, and the vacuum effect of bipolar vacuum is better than that of the single stage vacuum, but the price must be higher.

Send your message to us

Automatic Extrusion Blowing Machine for LED Light PC Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords