Three And Five Layers Co-Extrusion Film Blowing Machine /Plastic Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | nude packing or wooden case packing as your request |

| Delivery Detail: | 30 days after receipt 30%T/T as deposite |

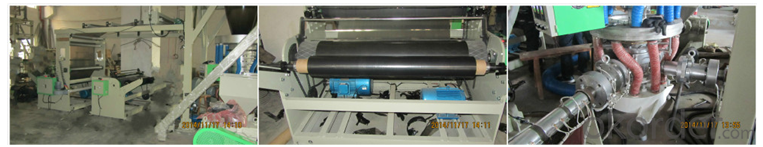

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

This machine set is to satisfy the customer’s requirements of high quality, high output film blowing equipment.

It adopts the extruder with force feeding function, precision type ceramic heater, precision type double vents air ring, horizontal type rotary traction system, fully automatic surface friction type double cut double winders, computer concentrate control system.

Advanced technique and equipments, compare with kindred equipment, it has the advantages such as more compact structure, high output, better produce quality, less energy consume, easier operation.

It can be widely used into various kind of high transparence packing film manufacture and create the considerable economic benefit for you.

Fully automatic double cut double winders

Optional parts:

Auto loaderX3pcs

Chiller

Corona

Full automatic winder

Embossing roller

collecting material drop

Technical data:

Model | MD-3L50 | MD-3L55 | MD-3L65 |

Suitable Material | LDPE LLDPE EVA HDPE | ||

Max Film Width(mm) | 1200 | 1500 | 2000 |

Film Thickness(mm) | LD:0.015-0.15 | ||

Max Extrusion Output LD | 140kg/hr | 200kg/hr | 280kg/hr |

Extrusion unit | |||

Gear Box | 146/173/146 | 173/200/173 | 200×3 |

Screw Diameter(mm) | φ50/55/50 | φ55/65/55 | φ65/65/65 |

Screw L/D Ratio | 28:1 | ||

Screw’s Material | 38 CRMOALA | ||

Barrel’s Material | 38 CRMOALA | ||

Barrel’s Cooling Fan | 370W×2×3 | 370W×2×3 | 370×3×3 |

Thermo Control (zone) | 3×3 | 3×3 | 4×3 |

Driving Motor (kw) | 15/22/15 | 22/30/22 | 30/30/30 |

Extrusion Die | |||

Die Size (mm) | LD:φ250/300 | LD:φ350/400 | LD:φ500 |

Rotary Die Head (mm) | 360°Continue Rotary | ||

Screen Changer | Manual Mechanics Screen Changer | ||

Thermo Control (zone) | 3 | 4 | 4 |

Air Ring | 1 PCS | ||

Cooling Blower (kw) | 5.5 | 7.5 | 11 |

Take-UP Unit | |||

Roller Width (mm) | φ165×1300 | φ165×1600 | φ190×2100 |

Take-UP Motor (kw) | 1.5 | 1.5 | 2.2 |

Take-UP Speed(M/min) | 5-60 | 5-60 | 5-60 |

Winding Unit | |||

Type OF Winder | Surface Friction Double Winder | ||

Roller Width (mm) | 1300 | 1600 | 2100 |

Winding Motor | 16N.M | 1.5kw | 1.5kw |

Winding Speed(M/min) | 5-60 | 5-60 | 5-60 |

Voltage | 380V, 50HZ, 3PHASE | ||

Cover Dimensions (m) | 6.8×2.6×6.5 | 7.5×3.2×7.5 | 9×4.2×9 |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

Machine at factory,double winder,simple type

Our other hot-sale machine(click the picture to know more information)

Company show

- Q: What is the difference in the filtration accuracy between the electrostatic oil purifier and the filter cartridge filter?

- The electrostatic oil purifier can effectively absorb impurities from 0.02 M to 100 mu m, with high accuracy. Filter is mainly used to filter method, the accuracy of high and low, and the filter clogging. However, electrostatic adsorption is not easy to plug, and most of the adsorbed impurities are discharged from the machine

- Q: How to assemble and disassemble the vacuum pump for power generation oil filter?

- In fact, if you understand the machine, it is easy to assemble and disassemble, but in order to avoid unnecessary trouble,

- Q: Centrifugal oil filter speed is not fast before, what is the matter?

- The pressure doesn't work. The higher the pressure, the faster the speed. Ah, you can try the hub instead

- Q: When peanut oil filter oil filter oil dregs particularly what is going on

- Oil filters are divided into a variety of centrifugal oil filters, vacuum, plate and frame, air pressure machine, here, under the centrifugal oil filter

- Q: Vacuum dewatering oil filter and coalescence separation dehydration, which dehydration effect is strong?

- Vacuum dehydration oil filters are in fact a general term for negative pressure power supply. What you should know is what method of dehydration is used If it is the coalescing filter, then it is the poly series dehydration product, but the direction of the power is different.At present, poly dehydration is king. As we all know, industrial petroleum products have a certain proportion of additives, whether centrifugal, heating or sedimentation methods will cause loss of additives.

- Q: Classification of oil filters According to the principle of the oil filter

- Viscosity of oilHigh viscosity oil can not pass through fine screen, so it is necessary to reduce the accuracy. Because: (1) filter often plug, need frequent cleaning, or even replace the filter.(2) the increase of the axial pressure, the oil can quickly pass filter, but tend to crush the filter.(3) adding preheated fuel tank to increase temperature and reduce viscosity.Generally speaking, the filtration precision of the fine filtration stage is chosen as:(1) insulating oil, choose 1~5 mu m.(2) lube oil and turbine oil under 46, select 10~20 mu m.(3) internal combustion engine oil and gear oil are chosen 20~50 mu m.

- Q: Transformer oil vacuum filter oil function, get rid of the smell of transformer oil?

- Transformer oil, heating, pumping, dehydration, degassing. The principle is to pump the oil tank into the vacuum, and to heat the transformer oil to form an oil mist with spraying method, so that the gas and water in the oil will escape.

- Q: Fig. 1 electrical control diagram of lubricating oil vacuum oil filter lv_80

- Each oil filter manufacturer's electrical control diagram has some differences, because the electrical control chart and vacuum oil filter structure and function are closely related, different manufacturers structure and control system there are some differences

- Q: How often does the oil filter in the turbine run oil filter change? Thank you for

- The oil pump pressure is also the object of surveillance. If you want to know how long it takes to change it, no one can say for sure.

- Q: How to choose the proper plate and frame pressure filter

- The frame pressure type oil filter is the simplest filter oil filter specially designed to filter impurities. It is simple in structure, simple in function, small in volume, and can be chosen as a suitable brand in comparison with several others

Send your message to us

Three And Five Layers Co-Extrusion Film Blowing Machine /Plastic Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords