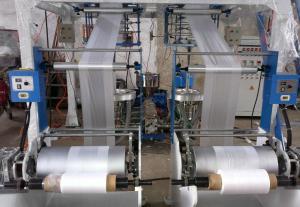

Polyethylene Blown Film Machine/Mini Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 99 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyethylene Blown Film Machine/Mini Film Blowing Machine

1.Specifications

1.HDPE/LDPE/LLDPE

2.bio/oxo degradable material

3.easy operation,big output

2.SJ-60-1000 mini film blowing machine

------------------------------------------------------------------------------------------------------------------------------

Use:

The machine suit for producing PP. It is widely used for packing food, garment, textile,

daily necessaries and industrial product etc.

------------------------------------------------------------------------------------------------------------------------------

Feature:

1. Die head can be turned in 360, it can strengthen the tension and evenness degree of film.

2. Screw stem and cylinder are all made of 38CRMOALA alloy, and has nitriding treatment.

It has an advantage of great thickness, corrosion resistance and endurance etc.

3. Die head has been chromed it's advantage of screw core structure, melting material extruding

evenly, and blowing film smoothly etc. Cooling equipment is labyrinth blow pump, which has

good effect. Especially it adopts the recycling cooling water system to ensure the best

transparent effect.

4. Discharging equipment adopt pressing braking winding equipment & center winding equipment,

and it adopts torque motor to adjust, has the merits of smooth film and convenient operation.

------------------------------------------------------------------------------------------------------------------------------

Model | XT-FB-40 | XT-FB-50 | XT-FB-60 | XT-FB-70 |

Diameter of screw stem | 40mm | 50mm | 60mm | 70mm |

Major diameter ratio of screw stem | 28:1(L/D) | 28:1(L/D) | 28:1(L/D) | 28:1(L/D) |

Rational speed of screw stem | 30-60r/min | 30-60r/min | 30-60r/min | 30-60r/min |

Specification of die head | 70mm | 90mm | 120mm | 150mm |

Thickness of products | 0.015-0.06mm | 0.015-0.06mm | 0.015-0.06mm | 0.015-0.06mm |

Main motor power | 7.5kw | 11kw | 15kw | 18.5kw |

Heating power | 12kw | 13kw | 16kw |

- Q: What's good for lubricating oil dehydrating and oil filters?

- There are three kinds of dehydrating principle of oil filter: vacuum, centrifugal and gathering.

- Q: The working principle of centrifugal oil filter

- Through the high-speed rotation of the centrifugal force of the drum and the dregs of oil to leave, liquid-solid separation. When the rotary drum stops rotating, the net oil is slid out of the drum to achieve the purpose of filtration. The oil quality is pure, and the experiment can be done on the fire at the time, fried fritters, stir frying dishes, no foam, no overflow pot. In the past we have used filtration equipment such as: frame filter, vacuum filter, pressure filter is called filter medium (media refers to the cloth, filter, filter cloth mesh) because the medium level of large dregs filtration process is filtered out, small particles through the mesh flow to the oil. This is the past, the filtration effect is relative to solve the quality issues, in operation, the crude oil inside the oil to plug the glial mesh after repeatedly opening the replacement of the filter cloth, cleaning cloth and post consumption.

- Q: What is the working principle of the oil filter?

- Which creates a driving force for the high-speed rotation of the rotor. Its speed can reach more than 4000-6000r.p.m, the power generated by the gravity of more than 2000 times, the principle of centrifugal force directly drive impurities from the oil in the separation.

- Q: How much is the 90 screw frying machine?

- Oil press related configuration, such as speculation machine, oil filter, peanut sheller, conveyor and so on the specific configuration.The difference between the new and the old, the old models of oil press consumption of TV, slow, relatively cheap price.

- Q: What are the types of oil filters? Oil filter?

- The third generation vacuum oil filter uses filter core filter to remove water and some impurities, and the fourth generation purifier does not use filter core, filter screen, filter cloth and filter paper to completely remove water and impurities.

- Q: Who knows what the vibration of the oil filter is?

- 3, the oil filter bearings damaged or to be lubricated. Solution: replace bearings or Wang oil.4, the foundation of the equipment is not strong enough. Solution: Foundation Reinforcement

- Q: What kind of cooking oil filter is good?

- What kind of oil filter do you choose? Tank pressure filter

- Q: Working principle of vacuum oil filter

- The vacuum oil purifier is designed according to the different boiling points of water and oil. It consists of a vacuum heating tank, a fine filter, a condenser, a primary filter, a water tank, a vacuum pump, an oil drain pump and an electric cabinet

- Q: What can I do to make the oil filtered by the centrifugal oil filter very bright?

- What you are using, general centrifugal filter is available, the filter effect is to see what you use the filter, and see you want to filter to what extent, generally need to consult with suppliers ah

- Q: What is the difference or connection between the oil filter and the oil filter?

- Second, the oil filter is usually fixed to a part of the system, and the oil filter is usually a mobile filter unit, without the need for fixed installation,

1. Manufacturer Overview

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyethylene Blown Film Machine/Mini Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 99 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords