Three to five layers co-extrusion film blowing machine set (IBC), extruder,Plastic blowing machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | nude packing or wooden case packing as your request |

| Delivery Detail: | 30 days after receipt 30%T/T as deposite |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

This machine set is to satisfy the customer’s requirements of high quality, high output film blowing equipment.

It adopts the extruder with force feeding function, precision type ceramic heater, precision type double vents air ring, horizontal type rotary traction system, fully automatic surface friction type double cut double winders, computer concentrate control system.

Advanced technique and equipments, compare with kindred equipment, it has the advantages such as more compact structure, high output, better produce quality, less energy consume, easier operation.

It can be widely used into various kind of high transparence packing film manufacture and create the considerable economic benefit for you.

Fully automatic double cut double winders

Optional parts:

Auto loaderX3pcs

Chiller

Corona

Full automatic winder

Embossing roller

collecting material drop

Technical data:

Model | MD-3L50 | MD-3L55 | MD-3L65 |

Suitable Material | LDPE LLDPE EVA HDPE | ||

Max Film Width(mm) | 1200 | 1500 | 2000 |

Film Thickness(mm) | LD:0.015-0.15 | ||

Max Extrusion Output LD | 140kg/hr | 200kg/hr | 280kg/hr |

Extrusion unit | |||

Gear Box | 146/173/146 | 173/200/173 | 200×3 |

Screw Diameter(mm) | φ50/55/50 | φ55/65/55 | φ65/65/65 |

Screw L/D Ratio | 28:1 | ||

Screw’s Material | 38 CRMOALA | ||

Barrel’s Material | 38 CRMOALA | ||

Barrel’s Cooling Fan | 370W×2×3 | 370W×2×3 | 370×3×3 |

Thermo Control (zone) | 3×3 | 3×3 | 4×3 |

Driving Motor (kw) | 15/22/15 | 22/30/22 | 30/30/30 |

Extrusion Die | |||

Die Size (mm) | LD:φ250/300 | LD:φ350/400 | LD:φ500 |

Rotary Die Head (mm) | 360°Continue Rotary | ||

Screen Changer | Manual Mechanics Screen Changer | ||

Thermo Control (zone) | 3 | 4 | 4 |

Air Ring | 1 PCS | ||

Cooling Blower (kw) | 5.5 | 7.5 | 11 |

Take-UP Unit | |||

Roller Width (mm) | φ165×1300 | φ165×1600 | φ190×2100 |

Take-UP Motor (kw) | 1.5 | 1.5 | 2.2 |

Take-UP Speed(M/min) | 5-60 | 5-60 | 5-60 |

Winding Unit | |||

Type OF Winder | Surface Friction Double Winder | ||

Roller Width (mm) | 1300 | 1600 | 2100 |

Winding Motor | 16N.M | 1.5kw | 1.5kw |

Winding Speed(M/min) | 5-60 | 5-60 | 5-60 |

Voltage | 380V, 50HZ, 3PHASE | ||

Cover Dimensions (m) | 6.8×2.6×6.5 | 7.5×3.2×7.5 | 9×4.2×9 |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

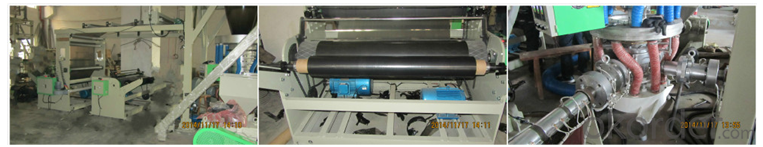

Machine at factory,double winder,simple type

Our other hot-sale machine(click the picture to know more information)

Company show

- Q: Dr. oil mill, bag filter, instructions for use

- Working principleThe vacuum oil filter is designed according to the different boiling points of water and oil. It consists of a vacuum heating tank, a fine filter, a condenser, a primary filter, a water tank, a vacuum pump, an oil drain pump and an electric cabinet.

- Q: Which is more practical, plate pressure type oil filter and multi-function oil purifier? What are their advantages and disadvantages?

- Therefore, the plate and frame oil filter basically can only filter impurities, moisture and gas impurities, plate and frame oil filter is powerless. Multifunctional oil purifier belongs to the vacuum oil filter, vacuum oil purifier is designed according to the boiling point of water and oil in different principle, it is composed of vacuum heating tank filter, a condenser, a primary filter, water tank, vacuum pump, drainage pump and electric cabinet. Vacuum pump to vacuum tank air to form a vacuum, outside the oil under the influence of the atmospheric pressure through the entrance pipe into the primary filter, remove larger particles, and then into the heating tank, after heating the 40~75 C oil through the automatic oil float valve, the valve is automatically controlled in a vacuum tank the amount of oil import balance. The heated oil is rapidly rotated through the jet wings to separate the oil into a half mist. The water in the oil evaporates rapidly into steam and is pumped into the condenser continuously by vacuum pumps. The steam enters the condenser after cooling back into the water discharge, oil heating in vacuum tank, pump are arranged into the filter through the filter or filter will filter out particulate impurities, thus completing the vacuum oil filter quickly remove impurities, the whole process of water and gas in oil, clean the oil from the oil discharge machine.

- Q: Vacuum oil filter which good problem description, we are in foreign countries have a project, is a hydropower plant with turbine oil, please professional recommend

- According to your description, if the filter of turbine oil (now known as turbine oil), then select TYAXD series special vacuum zjc can, if the impurity content, in order to guarantee the effect and save filter supplies, then you can also add a AXDLY frame oil filter machine is filtered through filter impurities. Then the turbine oil vacuum oil filter, the effect is better, the filter is not easy to be blocked, the cost of the book worth.The domestic production of vacuum oil filter to many companies, the effect is good, see you with domestic or imported configuration configuration, general configuration imports more expensive, imported configuration means oil pump, vacuum pump, control system, liquid level system adopts imported brands of accessories, the overall quality of life and certainly better, the price is expensive some. At present, the company here in Chongqing vacuum oil filter production of the most, high and low, have to see what grade you need. The cheapest sure, just cheap, regardless of quality and after-sale, the quality of mid-range points better, and after-sale guarantee, high-grade quality stability, small problems, and later services, after-sales service is certainly very thoughtful.Vacuum oil filter which is good, this need your purchasing department actual contrast investigation, can decide. You Words alone are no proof. oil filter manufacturers, search rankings, find a few companies compared with technical strength, quality, technology, oil filter configuration, price, customer service and so on, considering the ultimate choice of a good quality, good customer service, your satisfaction is the price.

- Q: Where can I get a good oil filter?

- There are many kinds of oil filters and they are widely used. First, you should know your specific requirements first. What is the filter medium?. Second, the oil filter will change the filter in the later stage, it is recommended that you buy oil filter manufacturers can also provide the filter, so that later replacement of the filter will be more labor-saving. Third, oil filter market price difference is relatively large, when buying as much as possible contrast. The major production bases in the country, in Chongqing, Xinxiang, Langfang and other places, the enterprises here to do a long time

- Q: The characteristics of plate and frame pressure oil filters? How often is the filter changed?

- The filter bed consists of multilayer filter plate and the filter frame, the filter media as paper or cloth lining the filter plate and the filter frame, with the pressure of the pressing device to filter plate and the filter frame to form a fixed filter chamber alone, tightly pressed between the filter plate and the filter frame of the paper or cloth filtration effect.

- Q: Oil filter HNP021-380-50-K-Z what does that mean?

- Just like you buy air conditioners, you don't stare at models, they only focus on function, quality, price, and after sale, and GREE and America don't have the same model. Buy the oil filter without looking at the model. Specifically, this model is explained as follows: HN is usually a brand or company initials

- Q: What's the difference between a purifier and an oil purifier? Or the purifier is the oil filter

- There is a difference between the oil purifier and the oil purifier,

- Q: The vane filter and the centrifugal oil filter are good

- The principle is not the same, the centrifuge is filtered by centrifugal force, and the relative processing capacity of the same model may be better

- Q: Operation description of turbine oil vacuum oil filter?

- Because it is located in a position similar to that of the steam seal, it is easy to enter steam (steam condenses into water in the oil). Cause there is middle water cut,

- Q: How much is the equipment for the oil press?

- Oil press complete sets of equipment, in general, the price of 20 thousand yuan -3 yuan.In general, the oil mill complete equipment configuration includes: fried material machine, oil press, oil filter.In addition, the workload is different, processing materials are different, hot and cold pressing method is different, the corresponding configuration is also different.

Send your message to us

Three to five layers co-extrusion film blowing machine set (IBC), extruder,Plastic blowing machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords