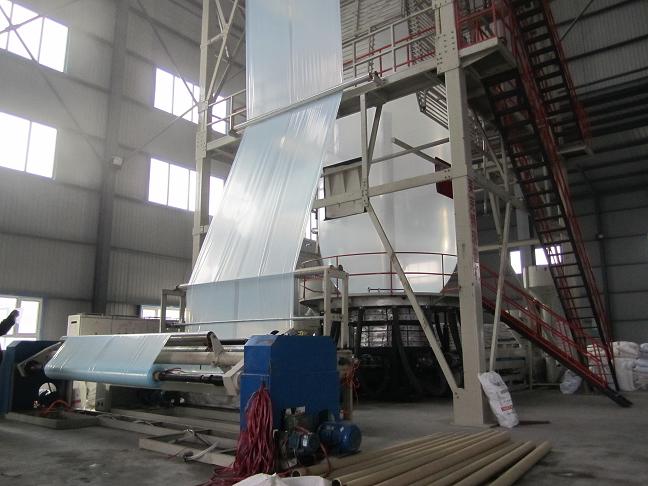

China Three-Layer Co-Extrusion Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Multi-layer Co-extrusion Greenhouse Film Blowing Machine

The lines is researched and designed on the basis of introducing and learning and assimilating the advanced key technology of Europe and America. It can be used for precess LDPE, LLDPE, MLLDPE, EVA, HDPE, etc. The line has various advantages such as Proper structure, stable function, nice plasticization, high output, low energy consumption and clear layers. It is the perfect device produce wide greenhouse film and geomembrane which have various function such as high strength, aging-resisting, non-fogdrop, light filtering and heat insulating.

Three-layer Coextrusion Film Blowing Machine (4-10m)

Main technical details:

1. Film Thickness: 0.05-0.2mm

Film Open Width: 4000-10000mm

Material: MLLDPE, LDPE, LLDPE, EVA

2. Material Mi range

1) LDPE: Mi=0.3-2.0

2) LDPE: Mi=0.3-2.0 EVA(5%~14%)

3) Mixed material (LLDPE and LDPE)

3. Single screw extruder:SJ120/30 (3 sets)

1) Capacity: 750kg/h

2) Screw Type: Wave type and mixed smelted head, used for processing of many material.

3) Screw Diameter: Φ 120mm (3 sets)

4) Screw L/D: 30: 1

5) Screw Material: 38CrMoALA\Nitrogen treated

6) Nitrogen treatment depth: 0.4-0.7mm, Surface hardness≥ HV950

7) Barrel Material: 38CrMoALA\Nitrogen treated

8) Processing Technics: Forging, Nitrogen HV≥ 750

9) Nitroged thickness: 0.4-0.7mm

10) Barrel temeperature controll: Constant temperature auto-controll

11) Barrel heating method: Cast aluminum heating

Barrel cooling method: Air-cooling

4. Gearbox: (Special for Plastic Machinery)

1) Gear Type: Standard hard gear

2) Gear Material: 20CrMoTi

3) Gear case lubricating method: Forcing oil lubricating

4) Main motor power: SJ120/30 with 132kw,

Three-phase asynchronism motor,

Frequency conversion

5) Equipped with long-acting screen changer equipment, to prolong screen changer

6) 120 Long-acting screen changer 3sets

5. Diehead

1) Sepecification: 1200× 2.0 (1 set)

2) Type: Three-layer coextrusion inner composite spiral die

3) Installation Method: Railway type diehead dolly

4) Heating Method: Casting aluminum heater

5) Temperature Controll: Auto-controll

6. Air Ring Equipment

1) Out Air Ring: 1 set

2) Air Ring Type: Double wind-nozzles structure

3) Cooling winder power: 22kw

4) Rotate Speed: 2900 rpm

5) Air pressure: 8000Mpa

6) Air capacity: > 3297m3/h

7. Inner Cooling Air Ring

Inner cooling controll system with PLC, It can improve the transparency and quality of film.

1) Controll system: PLC controll system, LCD Screen

2) Inner cooling blower: 2 sets, Frequency conversion timing

3) Intowinder: 15kw

4) Outwinder: 15kw

5) Imported ultrasonic sensor: 2 PCS

8. Haul off equipment

1) Upper haul off height: 21m

2) Die operation plat: 1 set

3) Triangle type frame: Steel frame rolling type 1 set

4) Flash board: Rolling type 1 set

5) Steady foam equipment: Rolling type 1 set

6) Upper haul off equipment: 1PC/set

7) Haul off roller sepecification: 340× 3200mm Speed: 0.5-15m/min

8) Motor power: 5.5kw

9. Tightening equipment and winding equipment: 1 set

1) Haul off roller sepecification: 200× 3200mm

2) Haul off Speed: 0.5-20m/min

3) Winding Method: Surface friction furl

4) Winding Speed: 0.5-20m/min

5) Winding motor type: YLJ132-40/6

10. The standard of checking machines

The machines will be fit for the standard as follows,

1) JB/T8061-96 Single screw plastic extruder

2) JB/78538-1997 Screw and Barrel equipped plastic machinery

3) JB/T8703-98 Plastic film blowing down-equippment

4) GB4340-84 The test method of metal hardness

5) GB11354-89 The standard of steel parts

6) GB11379-89 The standard of plating chrome

7) GB985-88 The type and size of welding

8) ZBG950/0-88 The condition and standard of painting

- Q: I would like to ask the following prawns, oil filters to do the sale, which customers should be running or units?

- First of all you need to know how much of this new technology on the market, the high precision is high precision, dehydration is dehydrated, sometimes people don't run with high energy consumption, what factory to see what people with oil, if the vacuum oil filter, I think the power plant is to run, because the power plant to remove water, vacuum the oil filter is dehydration,

- Q: What is the working vacuum in the oil filter?

- Therefore, the so-called "working vacuum" is the vacuum filter oil function, the completion of gas-liquid separation and oil-water separation function vacuum control range.

- Q: What is the difference in the filtration accuracy between the electrostatic oil purifier and the filter cartridge filter?

- The filter method is different, the filter oil filter is limited by the filter material,Electrostatic filtration is said to be free of impurities of any diameter.But I still don't know the principle of electrostatic filtration. Ha-ha

- Q: Which filter is the best for peanut oil filter?

- The peanut oil filter is divided into centrifugal oil filter, plate and frame oil filter and vacuum oil filter

- Q: What's good for lubricating oil dehydrating and oil filters?

- There are three kinds of dehydrating principle of oil filter: vacuum, centrifugal and gathering.

- Q: What are the oil filters for? What are they used for?

- The oil filter is generally used for on-line lubrication system of large equipment, that is, when large equipment is in normal operation

- Q: Application of vacuum oil filter

- Removal of impurity by net filtration combined with polymer adsorption

- Q: How to separate the rapeseed oil with centrifugal oil filter, how to use in the separation, how to use the water.

- The utility model relates to a high precision centrifugal filtering device for oil filters, which utilizes the high-speed rotation of the centrifugal body to rapidly separate the oil, water and impurities from different lubricating oils with different degree of pollution by different centrifugal forces

- Q: Which is more advantageous than a centrifugal oil filter and a vacuum oil filter?

- The first is to optimize the structure, centrifugal oil filter machine adopts the new centrifuge system is small, and thus the structural shape optimization of equipment can do better, smaller, less noise, the unit energy consumption decreased.

- Q: Which is the best vacuum oil filter?

- Imported oil filter prices are expensive, after-sales service is not convenient, accessories are expensive, therefore, the current domestic oil filter to buy the highest ratio of sexual intercourse, the current low-end markets are mainly domestic brands. High end oil filter, also has a few oil filter brand involved. Choose a good one. This depends on what oil you're filtering and the budget you want to buy. To protect the quality of customer service, security, oil filter machine accessories manufacturers certainly cheap machines are more expensive, after all, a penny goods, no company is willing to do business at a loss, the oil filter is not what a huge industry, now the price is substantially transparent.

Send your message to us

China Three-Layer Co-Extrusion Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords