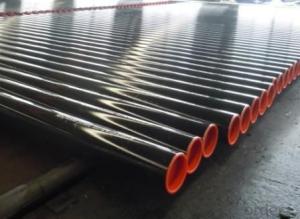

Thin Wall welded Stainless Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Outer diamete :6-90

Wall thickness:0.16-2.5

Material:201,304,201L,304L

Surface:Polih/hairline

Technics:Cold rolled

Product Description

| type | Thin Wall Thicknes Welded stainless steel tube |

| Materil | 201,304 |

| Application | Decoration,Bathroom… |

| specification | Outer diamete : 19*19-50*50 Wall thickness:0.16-2.5 |

| Length | 6m(as required) |

| surface | Polish/hairline(as required) |

| technics | Cold rolled |

- Q: Can stainless steel pipes be polished?

- Yes, stainless steel pipes can be polished.

- Q: Can stainless steel pipes be used for underground sewer lines?

- Certainly! Stainless steel pipes are suitable for underground sewer lines. Due to its remarkable durability and resistance to corrosion, stainless steel is an optimal material selection for harsh environments, including underground sewer systems. It offers exceptional protection against chemicals, moisture, and other corrosive elements frequently encountered in sewer lines. Moreover, stainless steel pipes boast an extended lifespan and necessitate minimal upkeep, proving to be an economical choice over time. Nevertheless, it is crucial to account for the particular specifications and regulations of the local sewer system before opting for stainless steel pipes in underground applications.

- Q: Can stainless steel pipes be used for construction purposes?

- Indeed, construction purposes can certainly make use of stainless steel pipes. This material, known for its exceptional durability and resistance to corrosion, proves itself suitable for a wide range of construction applications. It finds common employment in structural projects, providing dependable support for building frameworks, handrails, and support structures. Moreover, stainless steel pipes serve vital roles in plumbing systems, drainage systems, and HVAC systems. Notably, they often take precedence in construction endeavors that prioritize hygiene and cleanliness, such as hospitals, food processing plants, and laboratories. In summary, stainless steel pipes deliver exceptional strength, longevity, and resistance to rust and corrosion, rendering them an unwavering choice for construction endeavors.

- Q: How do you calculate the pipe length required for a specific application?

- To calculate the pipe length required for a specific application, there are several factors that need to be considered. 1. Flow Rate: Determine the desired flow rate or the amount of fluid to be transported through the pipe per unit of time. This can be measured in gallons per minute (GPM), liters per second (L/s), or any other appropriate unit. 2. Pipe Material: Identify the material of the pipe that will be used for the application. Different materials have different friction coefficients, which will affect the overall length required. 3. Friction Loss: Calculate the friction loss in the pipe based on the flow rate and the material properties. This involves determining the friction factor for the specific pipe material and using the appropriate equation (such as Darcy-Weisbach equation or Hazen-Williams equation) to calculate the friction loss. 4. Pressure Drop: Consider the desired pressure drop across the pipe. This is typically specified by the application requirements or system design. The pressure drop can be calculated using the Bernoulli's equation or other relevant equations. 5. Pipe Diameter: Determine the appropriate pipe diameter based on the desired flow rate and the allowable pressure drop. This can be done by using pipe sizing charts or equations specific to the pipe material and the flow characteristics. 6. Pipe Length Calculation: Once the pipe diameter is known, calculate the length required based on the desired flow rate, pressure drop, and the friction loss. This can be done using various pipe sizing equations or software tools available for the specific pipe material. 7. Additional Factors: Consider any additional factors that may affect the pipe length calculation, such as elevation changes, fittings, valves, or other components in the system. These factors may introduce additional friction losses or pressure drops that need to be accounted for. It is important to note that pipe length calculations are typically performed by engineers or professionals with expertise in fluid mechanics and pipe system design. Consulting relevant codes, standards, and guidelines specific to the application is also recommended to ensure compliance with safety and performance requirements.

- Q: Is galvanized steel pipe stainless steel pipe?

- Galvanized steel pipe is a kind of welded steel pipe, and its essence is hot-dip galvanized coating on the inner and outer surface of welded steel pipe. Hope to be of help to you.

- Q: Can stainless steel pipes be used for natural gas systems?

- Yes, stainless steel pipes can be used for natural gas systems. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for transporting natural gas safely and effectively.

- Q: Are stainless steel pipes suitable for architectural applications?

- Yes, stainless steel pipes are highly suitable for architectural applications. They offer excellent durability, corrosion resistance, and aesthetic appeal, making them an ideal choice for various architectural structures such as handrails, facades, and interior designs. Additionally, stainless steel pipes can withstand harsh weather conditions, maintain their appearance over time, and require minimal maintenance, further enhancing their suitability for architectural use.

- Q: Can stainless steel pipes be used for nuclear power plants?

- Yes, stainless steel pipes can be used for nuclear power plants. Stainless steel is a commonly used material in the construction of nuclear power plants due to its excellent corrosion resistance and high-temperature strength. These properties are essential for withstanding harsh operating conditions, such as high temperatures and corrosive environments, that are typically present in nuclear power plants. Additionally, stainless steel is known for its durability and long service life, making it a reliable choice for critical applications in the nuclear industry.

- Q: Can stainless steel pipes be used for pharmaceutical applications?

- Yes, stainless steel pipes can be used for pharmaceutical applications. Stainless steel is a common material of choice in the pharmaceutical industry due to its excellent corrosion resistance, durability, and hygienic properties. It is resistant to chemicals and can withstand high temperatures and pressure, making it suitable for various pharmaceutical processes such as fluid transportation, product transfer, and storage. Stainless steel pipes are easy to clean and maintain, which is essential in pharmaceutical applications where cleanliness and sterility are crucial. They have a smooth surface that prevents the accumulation of bacteria, ensuring the integrity of the pharmaceutical products. Additionally, stainless steel is non-reactive, meaning it will not contaminate the pharmaceutical products being transported through the pipes. Furthermore, stainless steel pipes can be manufactured to meet specific requirements, such as precise dimensions, high purity, and various finishes. This versatility allows for customization and adaptation to specific pharmaceutical processes and regulations. In summary, stainless steel pipes are suitable for pharmaceutical applications due to their corrosion resistance, durability, hygienic properties, ease of cleaning, and ability to meet specific requirements. They contribute to maintaining the quality and integrity of pharmaceutical products throughout the manufacturing process.

- Q: Can stainless steel pipes be used for sewage disposal?

- Yes, stainless steel pipes can be used for sewage disposal. Stainless steel is highly resistant to corrosion, making it a suitable material for sewage pipes that are exposed to various chemicals and moisture. Additionally, stainless steel pipes have smooth surfaces, which helps prevent the buildup of debris and facilitates the flow of sewage.

Send your message to us

Thin Wall welded Stainless Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords