Large diameter longitudinal submerged arc welded pipe API

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. Specification of large diameter longitudinal submerged arc welded pipe:

1)Application: It is widely applied to line pipe in oil and sewage transportation , and it is used in Low pressure liquid and gassy transportation and it is also good Structure pipe in building and bridge field.

2)Grade:API 5L GR.B, X40, X42, X52, X56, X60, X65, X70.ST37/37-2,ST33,ST35.8,ST35.4.GB 9711.1/SY5037/GB3092

3)Standard:ASTM A53,ASTM A671 ,ASTM A672 .ASTM A252 API 5L (PSL-1,PSL-2) ,API 5L 2B ,2H,2W.DIN1626,DIN17175,DIN1629.JISG 3452,JISG3457/3456,JISG3461.GB 9711.1/SY5037/GB3092

2.Size of large diameter longitudinal submerged arc welded pipe:

OD: 406.4MM-1422MM (16”-56”)

Thickness: 8MM-50.8MM depends on OD

3.Data Sheet for large diameter longitudinal submerged arc welded pipe:

Standard: APISPEC 5L

Mechanical Properties

Standard | Grade | (MPa) | (MPa) | ||

Yield strength | Tensile Strength | ||||

API SPEC 5L | PSL1 | ||||

B | ≥241 | ≥414 | |||

×42 | ≥290 | ≥414 | |||

×46 | ≥317 | ≥434 | |||

×52 | ≥359 | ≥455 | |||

×56 | ≥386 | ≥490 | |||

×60 | ≥414 | ≥517 | |||

×65 | ≥448 | ≥531 | |||

×70 | ≥483 | ≥565 | |||

PSL2 | |||||

| Min | Max | Min | Max | |

B | 241 | 448 | 441 | 758 | |

×42 | 290 | 496 | 414 | 758 | |

×46 | 317 | 524 | 434 | 758 | |

×52 | 359 | 531 | 455 | 758 | |

×56 | 386 | 544 | 490 | 758 | |

×60 | 414 | 565 | 517 | 758 | |

×65 | 448 | 600 | 531 | 758 | |

×70 | 483 | 621 | 565 | 758 | |

Chemical Composition(%)

Standard | Grade | C | Mn | P | S | CEV |

Max | Max | Max | Max | Max | ||

PSL1 |

- | |||||

B | 0.26 | 1.2 | 0.030 | 0.030 | ||

×42 | 0.26 | 1.3 | 0.030 | 0.030 | ||

×46,×52,×56,X60 | 0.26 | 1.4 | 0.030 | 0.030 | ||

X65 | 0.26 | 1.45 | 0.030 | 0.030 | ||

X70 | 0.26 | 1.65 | 0.030 | 0.030 | ||

PSL2 |

0.43 | |||||

B | 0.22 | 1.20 | 0.025 | 0.015 | ||

×42 | 0.22 | 1.30 | 0.025 | 0.015 | ||

×46,×52,×56, X60 | 0.22 | 1.40 | 0.025 | 0.015 | ||

X65 | 0.22 | 1.45 | 0.025 | 0.015 | ||

X70 | 0.22 | 1.65 | 0.025 | 0.015 | ||

4. Packing & Delivery

Packing Detail: bundles with anti-rust painting and with plastic caps

Delivery Term: 30 days after receving payment or L/C

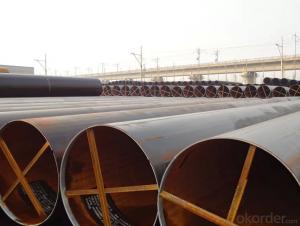

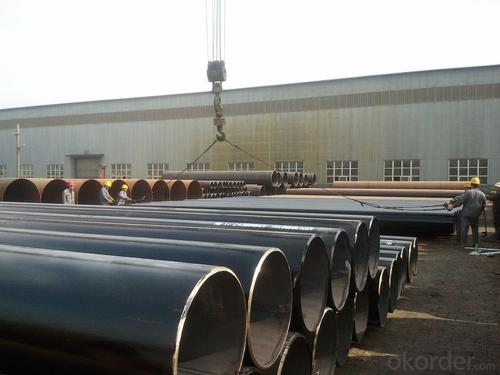

5. Products picture for large diameter longitudinal submerged arc welded pipe:

6. FAQ of large diameter longitudinal submerged arc welded pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

- Q: Does the seamless steel pipe need rust removal?

- Chemical and electrolytic methods are generally used for pickling treatment. The pipeline corrosion only uses chemical pickling, which can remove oxide, rust and old coating. Sometimes, it can be treated as sand blasting after rust removing. Two. Although chemical cleaning can make the surface reach a certain degree of cleanliness and roughness, but its anchor grain is shallow, and easy to pollute the environment.

- Q: How do steel pipes compare to other materials like PVC or copper pipes?

- Steel pipes have numerous advantages over materials such as PVC or copper pipes. Firstly, their strength and durability make them ideal for high-pressure applications. They can withstand extreme temperatures and resist corrosion, making them suitable for both indoor and outdoor use. In contrast, PVC pipes are weaker and more prone to cracking and breaking under pressure or in extreme temperatures. Although copper pipes are durable, they can be susceptible to corrosion and may require additional protective coatings. Secondly, steel pipes have a longer lifespan compared to PVC or copper pipes. They are renowned for their longevity and can last for several decades without needing replacement. PVC pipes, although relatively inexpensive, have a shorter lifespan and may require more frequent replacement. Similarly, copper pipes can corrode over time and may need maintenance or replacement. Another advantage of steel pipes is their ability to handle a wide range of fluids and substances. They are commonly used in industrial applications where chemicals or corrosive materials may be present. PVC pipes, on the other hand, may not be suitable for handling certain chemicals or substances as they can react and cause damage to the pipe. Copper pipes, while generally safe for carrying water, may not be ideal for conveying certain chemicals or fluids. Additionally, steel pipes possess excellent fire resistance properties. In the event of a fire, they can withstand high temperatures and maintain their structural integrity, ensuring the safety and protection of the surrounding area. PVC pipes, however, can melt or deform under high heat, potentially causing structural damage. Although copper pipes are less prone to melting, they can still be affected by extreme heat and lose their strength. Nevertheless, steel pipes do have a few drawbacks. They tend to be heavier and more challenging to install compared to PVC or copper pipes. Additionally, they can be more expensive upfront, especially when compared to PVC pipes. However, considering their durability and longevity, steel pipes may offer better value in the long run. In conclusion, steel pipes provide numerous advantages over materials like PVC or copper pipes. They are strong, durable, resistant to corrosion, and have a longer lifespan. They can handle high-pressure applications and a wide range of fluids, making them suitable for various industrial and commercial uses. Although they may be more expensive and difficult to install, the benefits of steel pipes make them a reliable and cost-effective choice for many applications.

- Q: What are the common methods of joining steel pipes?

- The common methods of joining steel pipes include welding, threading, and using mechanical couplings. Welding involves fusing the pipes together using heat, while threading involves screwing the pipes together using threads on the ends. Mechanical couplings are devices that connect the pipes together using compression or other means.

- Q: Can steel pipes be used for both high-pressure and low-pressure systems?

- Yes, steel pipes can be used for both high-pressure and low-pressure systems. Steel is known for its durability, strength, and resistance to extreme conditions, making it suitable for various applications. Whether it is transporting liquids or gases in high-pressure systems or low-pressure systems, steel pipes can efficiently handle the demands of both.

- Q: Are steel pipes suitable for structural applications?

- Yes, steel pipes are suitable for structural applications due to their high strength, durability, and versatility. They are commonly used in various construction projects such as buildings, bridges, and infrastructure due to their ability to bear heavy loads, resist corrosion, and withstand extreme weather conditions.

- Q: What are the different manufacturing standards for steel pipes?

- There are several manufacturing standards for steel pipes that are widely recognized and implemented in the industry. These standards ensure that the steel pipes are produced to meet specific requirements and quality standards. Some of the most common manufacturing standards for steel pipes include: 1. American Society for Testing and Materials (ASTM): ASTM standards are widely used in the United States and cover a wide range of steel pipe specifications. These standards include specifications for seamless and welded steel pipes, as well as various grades and dimensions. 2. International Organization for Standardization (ISO): ISO standards are globally recognized and provide guidelines for the production of steel pipes. ISO standards cover areas such as dimensions, materials, testing, and quality control. 3. European Norm (EN): EN standards are applicable in Europe and provide specifications for various types of steel pipes. These standards cover aspects such as dimensions, materials, manufacturing processes, and testing. 4. Japanese Industrial Standards (JIS): JIS standards are widely used in Japan and have gained international recognition. These standards cover dimensions, materials, and testing methods for steel pipes. 5. British Standards (BS): BS standards are commonly used in the United Kingdom and cover a range of steel pipe specifications. These standards include requirements for dimensions, materials, and testing procedures. 6. American Petroleum Institute (API): API standards are specifically developed for the oil and gas industry and cover various aspects of steel pipe manufacturing. These standards include specifications for seamless and welded pipes used in oil and gas exploration, production, and transportation. It is important for manufacturers, buyers, and users of steel pipes to be aware of these standards to ensure the quality, compatibility, and reliability of the pipes. Compliance with these standards helps to ensure that the steel pipes meet the necessary requirements and are suitable for their intended applications.

- Q: What are the factors to consider when selecting pipe materials for high-temperature applications?

- When choosing pipe materials for high-temperature applications, several factors must be taken into account. First and foremost, the thermal conductivity of the material is crucial. Efficient heat transfer and prevention of heat buildup are necessary in high-temperature applications, therefore materials with high thermal conductivity, like copper and stainless steel, are commonly used in these installations. Secondly, it is important to consider the material's resistance to thermal expansion. Pipes tend to expand when exposed to high temperatures, so selecting materials with low thermal expansion coefficients is vital to avoid deformation and potential pipe failure. Carbon steel and stainless steel are suitable options as they exhibit relatively low thermal expansion. The material's mechanical strength and resistance to corrosion should also be considered. High temperatures can weaken or corrode certain materials, leading to structural failures. Therefore, it is essential to choose materials, such as alloy steel and nickel-based alloys, that can withstand high temperatures without compromising their mechanical strength or corroding easily. Additionally, the cost and availability of the materials should be taken into account. Some high-temperature pipe materials may be expensive or hard to obtain, which can impact the project's budget and timeline. It is important to find a balance between the desired material properties and the project's financial and logistical constraints. Lastly, it is crucial to consider the specific application requirements and industry standards. Different industries may have guidelines or regulations regarding pipe materials for high-temperature applications. Ensuring that the selected materials comply with these standards is essential for safety, reliability, and adherence to industry regulations. To conclude, the factors to consider when choosing pipe materials for high-temperature applications include thermal conductivity, resistance to thermal expansion, mechanical strength, resistance to corrosion, cost and availability, and compliance with industry standards. By carefully evaluating these factors, one can select the most suitable pipe material to ensure efficient and reliable operation in high-temperature environments.

- Q: How are steel pipes used in the renewable energy industry?

- Steel pipes are commonly used in the renewable energy industry for various applications. They are used to transport fluids, such as water or steam, in geothermal power plants. Steel pipes are also used in solar thermal power plants for transferring heat transfer fluids. Additionally, steel pipes are utilized in the construction of wind turbine towers, providing structural support for the turbines. Overall, steel pipes play a vital role in the renewable energy industry by facilitating the efficient and reliable operation of different renewable energy technologies.

- Q: Are steel pipes suitable for potable water systems?

- Yes, steel pipes are suitable for potable water systems. They are known for their durability, strength, and resistance to corrosion, making them an excellent choice for transporting and distributing clean drinking water. However, it is important to ensure proper coating and maintenance to prevent any potential contamination or degradation of water quality.

- Q: Is it good to buy a simple wardrobe or a steel pipe?

- Natural nobility, if the quality and the degree of firmness, is the simple steel cloth cabinet is the best. However, because the texture of wood wardrobe, solid wood wood may be used after deformation.

Send your message to us

Large diameter longitudinal submerged arc welded pipe API

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords