ERW Steel Pipe Welded Black ERW Steel Pipe ASTM A53

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Welded Black ERW Steel Pipe ASTM A53 :

Welded Black ERW Steel Pipe ASTM A53 is electric resistance welding, the abbreviation for ERW for transporting oil and natural gas vapor liquid objects, can meet the requirements of high and low pressure, the transport in the world with pipe sector accounted for a pivotal position.With sound reputation and high quality , we will offer clients a wonderful business experience.

2、Main Features of Welded Black ERW Steel Pipe ASTM A53 :

• High manufacturing accuracy

• Good visual effect

• Good view and appearance

• Good shape

• Reasonable price

• Strong heat dissipation ability

3、Welded Black ERW Steel Pipe ASTM A53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 1 - 33 mm |

Section Shape | Round |

Outer Diameter | 21 - 610mm |

Place of Origin | Tianjin, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Welded Black ERW Steel Pipe ASTM A53 :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

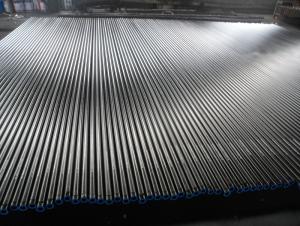

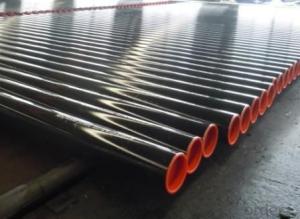

6、 Welded Black ERW Steel Pipe ASTM A53 Images:

- Q: How do steel pipes perform in corrosive environments?

- Steel pipes perform well in corrosive environments due to their natural corrosion resistance. The addition of protective coatings or linings further enhances their performance, making them highly durable and suitable for a wide range of applications in such environments.

- Q: What is the difference between internal and external coating of steel pipes?

- The main difference between internal and external coating of steel pipes lies in the purpose and location of the coatings. The internal coating is applied on the inner surface of the steel pipe to protect it from corrosion and ensure smooth flow of the contents within the pipe. It is commonly used to prevent contamination of the transported liquid or gas and to extend the lifespan of the pipe. On the other hand, the external coating is applied on the outer surface of the steel pipe to protect it from environmental factors such as moisture, chemicals, and physical damage. It helps to prevent corrosion and maintain the structural integrity of the pipe, especially in harsh conditions. Overall, while the internal coating focuses on the functionality and preservation of the transported contents, the external coating primarily aims at safeguarding the pipe itself from external influences.

- Q: How to perform nondestructive inspection of steel tubes

- Including fluorescence, coloring two kinds. Because of its simple equipment and convenient operation, it is an effective method to check the surface defect of magnetic particle inspection. It is mainly used for surface defect inspection of non-magnetic materials.

- Q: What is the maximum temperature and pressure that steel pipes can withstand?

- The maximum temperature and pressure that steel pipes can withstand vary depending on the specific grade and type of steel being used. However, in general, steel pipes can withstand high temperatures and pressures due to their strong and durable nature. For high-temperature applications, such as in steam or heat transfer systems, steel pipes can typically withstand temperatures up to 1000 degrees Celsius (1832 degrees Fahrenheit) or even higher. It is important to note that the specific temperature limit may vary depending on the alloy composition and heat treatment of the steel. Regarding pressure, steel pipes are known for their excellent strength and resistance to internal and external pressure. The maximum pressure that steel pipes can withstand will depend on factors such as the pipe diameter, wall thickness, and material strength. In industrial applications, steel pipes can withstand pressures ranging from a few hundred psi (pounds per square inch) to several thousand psi. To ensure the safe operation of steel pipes under high temperatures and pressures, it is crucial to follow industry standards and guidelines, as well as perform regular inspections and maintenance. Consulting with engineers and professionals experienced in steel pipe systems can provide more specific information regarding the maximum temperature and pressure limits for a particular steel pipe application.

- Q: Can steel pipes be recycled and used for other purposes?

- Yes, steel pipes can be recycled and used for other purposes. Due to their durability and strength, steel pipes can be melted down and repurposed for various applications, including construction, manufacturing, and infrastructure projects. Recycling steel pipes not only saves resources but also contributes to reducing waste and promoting sustainability.

- Q: Can steel pipes be used for natural gas processing plants?

- Yes, steel pipes can be used for natural gas processing plants. Steel pipes are commonly used in the oil and gas industry due to their high strength, durability, and resistance to corrosion. They can safely transport natural gas and are capable of withstanding the high pressure and temperature conditions typically found in processing plants.

- Q: How are steel pipes used in the manufacturing of structural frameworks?

- Steel pipes are commonly used in the manufacturing of structural frameworks due to their strength, durability, and versatility. They provide a reliable means of connecting and supporting various components, allowing for the creation of robust and stable structures. Steel pipes are often used as columns, beams, and braces, providing essential support and stability to buildings, bridges, and other infrastructure projects. Additionally, steel pipes can be easily customized and fabricated to meet specific design requirements, making them a popular choice in the construction industry.

- Q: What are the different standards for steel pipe manufacturing?

- There are several different standards for steel pipe manufacturing, including ASTM (American Society for Testing and Materials), ASME (American Society of Mechanical Engineers), API (American Petroleum Institute), and DIN (Deutsches Institut für Normung). These standards provide specifications for various aspects of steel pipe production, such as dimensions, chemical composition, mechanical properties, and testing procedures. Compliance with these standards ensures the quality and reliability of steel pipes for different applications and industries.

- Q: How are steel pipes used in the manufacturing of solar power systems?

- Steel pipes are commonly used in the manufacturing of solar power systems for various purposes. They are used as structural supports for solar panels, providing stability and durability. Additionally, steel pipes are often utilized for the transportation of fluids such as water or heat transfer fluids, enabling the efficient circulation of these substances within the solar power system.

- Q: What are the different types of steel pipe coatings?

- There are several types of steel pipe coatings, including epoxy coatings, polyethylene coatings, polyurethane coatings, and zinc coatings. These coatings help protect the steel pipes from corrosion, increase their lifespan, and improve their performance in various environments.

Send your message to us

ERW Steel Pipe Welded Black ERW Steel Pipe ASTM A53

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords