Textured and Perforated HDPE/PP Plastic Geocell with Geotextile Fabric for Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Textured and Perforated HDPE / PP plastic Geocell:

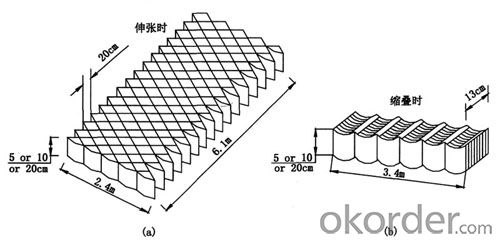

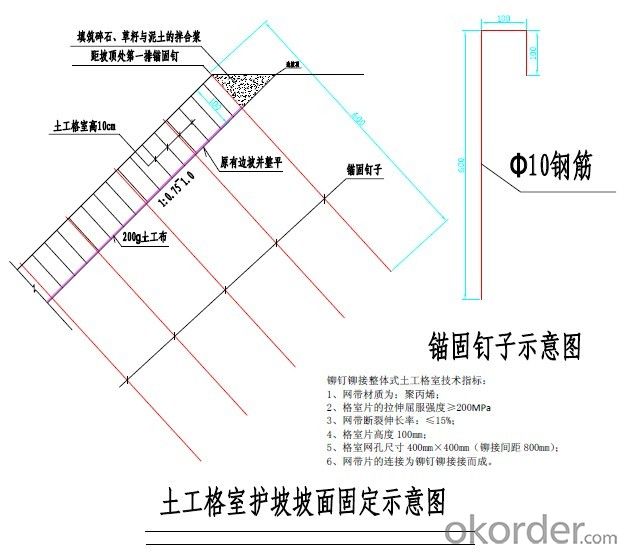

Geocell shaped like honeycomb,with High density PE,widely use for fasten slope and river,keep the project long time ensurance.We can product various kinds of Geocell for different requirement of project.

Main Features of Textured and Perforated HDPE / PP plastic Geocell:

1.Light weight , wear resistant, chemical stability, light oxidation and aging resistant

2.Wide temperature range, hihgtensile strength, good rigidity and toughness,good load capacity and erosion-resistance ability.

3.Size can be various and change the dimension to meet the needs of different projects.

4.Retractile and easy to transport and use,can use local materials and achieve rapid contruction,reduce construction costs.

Specifications of Textured and Perforated HDPE / PP plastic Geocell:

Geocell now widely use for projects like Roads Railways Aquaculture Effluent traetment Plants Reservoirs and Canals.

Specification | height | Reverting | Open length | Open width | Plate tensile strength | Elongation | Reverting strength |

YT50-500 | 50 | 500 | 12500 | 4000 | 150 | 15 | 15 |

YT100-500 | 100 | 500 | 12500 | 4000 | 150 | 15 | 15 |

YT150-500 | 150 | 500 | 12500 | 4000 | 150 | 15 | 15 |

YT200-500 | 200 | 500 | 12500 | 4000 | 150 | 15 | 15 |

YT80-500 | 80 | 500 | 12500 | 4000 | 150 | 15 | 15 |

Applications of Textured and Perforated HDPE / PP plastic Geocell:

Weldding: Ultrasonic

Height: 100MM-200MM

Weldding distance: 300mm-500mm

Surface treatment: With texture,smooth,or perforated as per requirement

Width: 1M-5M or as per required

IMages of Textured and Perforated HDPE / PP plastic Geocell:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What are geotextiles?

- Geotextiles are synthetic fabrics made from polypropylene or polyester that are used in civil engineering and construction to improve soil stability, drainage, and erosion control. They are permeable and provide strength and reinforcement to various applications such as roadways, retaining walls, and landfills.

- Q: Can geotextiles be used in land reclamation projects?

- Yes, geotextiles can be used in land reclamation projects. Geotextiles are commonly used in these projects to stabilize and reinforce soil, control erosion, and promote vegetation growth, ultimately enhancing the overall success and durability of the reclaimed land.

- Q: Geotextile with the welding tool where to buy

- Local Hardware & Electrical City, about 5000 or so

- Q: What are the factors to consider when designing with geotextiles?

- When designing with geotextiles, there are several factors that need to be considered. These include the specific application or purpose of the geotextile, the physical and mechanical properties of the geotextile, the site conditions and environmental factors, the installation methods and techniques, and the long-term performance and durability requirements. Additionally, factors like cost, availability, and compatibility with other materials should also be taken into account during the design process.

- Q: Can geotextiles be used for reinforcement of canal banks?

- Yes, geotextiles can be used for the reinforcement of canal banks. Geotextiles are permeable fabric materials that are commonly used in civil engineering applications for soil stabilization and erosion control. When used in canal banks, geotextiles can provide additional strength and stability to the soil, preventing erosion and protecting the banks from damage caused by water flow.

- Q: What are the different geotextile tensile strength test methods?

- There are several different geotextile tensile strength test methods, including the grab test, strip test, wide-width strip test, and trapezoidal tear test. These methods involve applying a force to the geotextile specimen and measuring the resulting tensile strength or resistance to tearing.

- Q: How do geotextiles aid in the reduction of soil settlement?

- Geotextiles aid in the reduction of soil settlement by providing reinforcement and stabilization to the soil. These synthetic materials are woven or non-woven fabrics that are placed between soil layers to distribute loads and improve the overall strength of the soil. By preventing the movement of soil particles, geotextiles help to mitigate settlement, which can occur due to factors such as poor soil quality, moisture changes, or heavy loads.

- Q: What is the length of the lap in the geotextile in the tunnel?

- General 20cm can be, I produce geotextile materials

- Q: Do you have to have a mattress on the geotextile?

- 1, geotextile must be washed back to fill or sand protective layer and light compaction to prevent the subsequent construction of the destruction of geotextile, punctured and so on. But also a transition zone, to ease the upper load on the geotextile extrusion, tensile force and so on. 2, "Geotextile Construction Code QB / SNGSG-2004" and "Geosynthetics Application Technical Specifications GB / T-2017" backfill requirements: 1) timely backfill materials, backfill stone maximum drop of not more than 300mm, Heavy earth stones should not roll on the slope of the rolling; 2) fill the compaction should meet the design requirements, backfill 300mm loose layer, light compaction. 3, geotextile introduction: 1), geotextile by synthetic fiber through acupuncture or weaving made of permeable geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Advantages: geotextile with excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with a light weight, high tensile strength, good permeability, high temperature, resistance to Freezing, anti-aging, corrosion-resistant advantages. 2), Disadvantages: in the rigid base waterproof requirements are not applicable (tensile rate does not meet the requirements), easy to break, scratches and so on.

- Q: What are the different testing methods for geotextiles?

- There are several testing methods for geotextiles, including tensile strength testing, puncture resistance testing, tear resistance testing, elongation testing, and permeability testing. These methods help assess the performance and quality of geotextiles in various applications, such as soil stabilization, erosion control, and drainage systems.

Send your message to us

Textured and Perforated HDPE/PP Plastic Geocell with Geotextile Fabric for Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords