High Quality HDPE Textured and Perforated Geocell with Geomembrana PVC for Slope Protection, Mine Covering, Environment

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

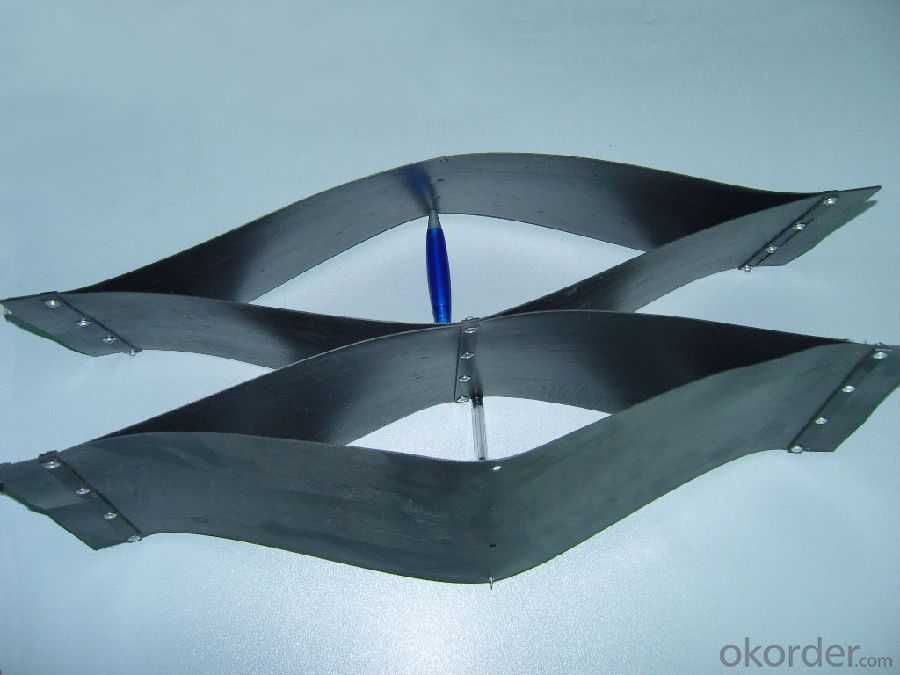

Description Of HDPE Textured and Perfomated GEOCELL for Slope Protection:

We produce and supply high quality of geocell for many years,all our products are exported to many countries and area.Welocme your inquiry to talk more details.

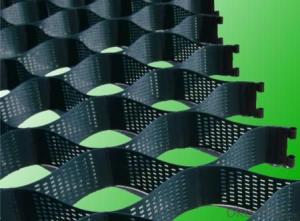

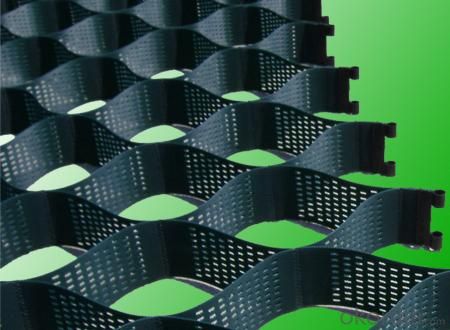

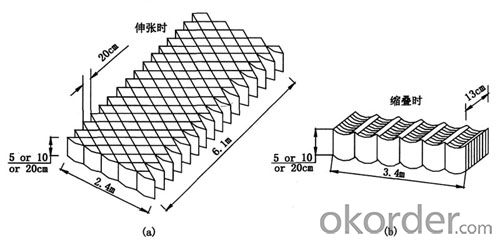

Geocell is a new type of high-strength geosynthetics, which is popular in domestic and abroad. It is a kind of three-dimensional network structure shaped by high-strength HDPE sheets through ultrasonic welding of high strength. Currently, it is being widely used in construction, such as highway, railway, bridge, dyke, etc.

Main Features of HDPE Textured and Perfomated GEOCELL for Slope Protection:

1.To stable the roadbed of railway and highroad.

2. To bear the load of dike or retaining wall.

3. To support the pipeline and sewer.

4. For the prevention of landside by using geocell as a heavy-duty hybrid force retaining wall.

5. For the desert, beaches and the riverbed, the river bank's regulation.

Specifications of HDPE Textured and Perfomated GEOCELL for Slope Protection:

Item | Height(mm) | Welding Distance(mm) | Thickness (mm) | Tensile Strength of Welding Points(N/cm) | Tensile Strength of Connection of Cells(N/cm) | Tensile Strength at Yield of Each Sheet(Mpa) |

Smooth and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Smooth and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Textured and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

Textured and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

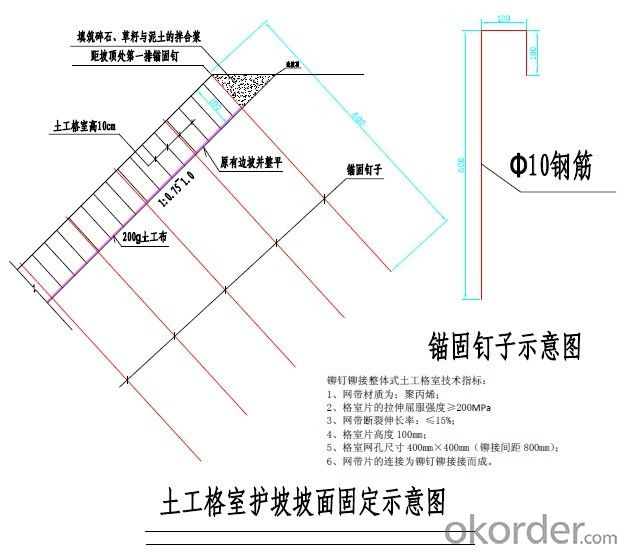

Applications of HDPE Textured and Perfomated GEOCELL for Slope Protection:

*Erosion Control

*Load Support

*Slope Protection

*Channel Protection

*Retaining Wall

*Ground Stabilisation

now most of our products are exported to Chile,Mexico,Brazil, Argentina , Russia, Poland, Turkey, USA, UK, Iran,and etc.

IMages of HDPE Textured and Perfomated GEOCELL for Slope Protection:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Which kind of the mobile phone screen protector is better?

- Films are generally divided into two types of membrane of high grade of transparency and frosted membrane. Membrane of high grade of transparency has high permeability through the natural brightness, it looks bigger brightness, but the drawback is reflection of light in the bright place which will make you harder to clearly see the text on the screen. But the frosted membrane has uneven surface, it is diffuse reflection when the light shines on it, so the screen will not be too harsh but soft with low light transmission.

- Q: Can geomembranes be used for golf course water features?

- Yes, geomembranes can be used for golf course water features. Geomembranes are impermeable liners that are commonly used to prevent water seepage and control water flow. They can be used to line ponds, lakes, and other water features in golf courses to ensure proper water containment and prevent leakage.

- Q: It the plastic wrap breathable?

- If the preservative film is breathable, it will not be good in fresh-keeping. There are strict control indicators in the regulations of the breathability PE preservative film according to the national standard. Here there are problems of breathability and tensile?strength facing us. For example, the oxygen permeability is stipulated within the range of 7000-20000, while the water permeability is required to be as less as possible.

- Q: What is the difference between the matte stick membrane and HD stick membrane?

- HD has a good light transmittance, when looking the video it is more clear, but it is not wear-resistant, easy to have scratches, and some of them are not easy to slide up. Grinding is more wear-resistant, when sliding up it is smoothly, but there is a little bit difference in light transmittance. when watching the video, it may have a little impact on the quality of the picture what film should be use depends on how you usually use.

- Q: What are the considerations for geomembrane installations in high-wind areas?

- When installing geomembranes in high-wind areas, several considerations need to be taken into account. Firstly, the selection of a suitable geomembrane material with a high tensile strength and resistance to tearing is crucial. The installation techniques should also be tailored to withstand strong winds, which may involve using additional anchoring methods, such as ballasting or mechanical fastening, to ensure the geomembrane remains securely in place. Furthermore, the design of the geomembrane system should consider wind load calculations, taking into consideration factors such as wind direction, duration, and gustiness. Regular inspections and maintenance should be conducted to identify and address any potential wind-related damage or stress on the geomembrane. Overall, a comprehensive understanding of the site-specific wind conditions and the appropriate design and installation measures are essential for a successful geomembrane installation in high-wind areas.

- Q: Can the electrothermal?film be used in bathroom?

- The electrothermal?film can be installed in bathrooms, the electrothermal?film heater uses transparent high temperature electrothermal?film as heating material, which is at the advanced level of the world in terms of techniques. It uses hot air duct structure. The traditional mode is enhancing convention, and the warm start speed is fast, and the outlet air temperature can be above 100 degrees in 3 minutes. Advantages: there is no oxidation when the electrothermal?film is heating, the service life can be 100 thousand hours, and it is small in size, beautiful in appearance, and it belongs to update products of electric?heater. Disadvantages: it quickly cools as power off, consumers in newly decorated houses will install a bath heater which is convenient for heating in shower. Bath heater is a newly introduced product in recent years from Australia. The ingenious combination of special waterproof infrared lights and ventilators mixes heating, ventilation and infrared physiotherapy and a variety of functions together. Due to the use of infrared radiation technology, the heat will be bigger, thermal efficiency is higher and more energy efficient. Electrothermal?film heater uses a new high efficiency material, the safety significantly increases, thermal efficiency is relatively high.

- Q: can RO membrane film be used to water purifier?

- Water purifier can use RO membrane because RO film can reverse osmosis membrane and heavy metal and toxic materials. RO reverse osmosis water purifier uses a reverse osmosis membrane filtration technology. Reverse osmosis membranes can filter selectively, its precision can reach 0.0001 micron, which can dissolve in water harmful heavy metals, scale, bacteria, and other contaminants and then become concentrated water to be discharged, the water molecules in the raw water preserved for drinking. After entering the human body, the part that human body can absorb has been preserved, non-absorbable metabolism excreted. Thus, reverse osmosis water purification equipment "kidney" in the world.

- Q: High density polyethylene root-resistant geomembrane

- High density polyvinyl chloride root puncture resistant geomembrane, aslo called high density PVC root resistant membrane, is a kind of geomembrane which has good seepage-proof effect and good resistance to puncture as well. High density PVC root resistant membrane, with good flexibility and puncture resistance, can be used in a variety of complex construction environment. The width of common High density PVC root resistant membrane in current market is 2m. You can use dedicated welding machine when paving a large area of high density PVC root resistant membrane. Besides, the high density polyethylene root puncture resistant geomembrane in market is also called HDPE root resistant membrane which has better anti-seepage effect, anti-puncture ability and longer service life than High density polyvinyl chloride root puncture resistant geomembrane. It is also cheaper than High density polyvinyl chloride root puncture resistant geomembrane so it can completely replace High density polyvinyl chloride root puncture resistant geomembrane. The width of high density polyethylene root acupuncture resistant geomembrane in current market is 8m, which the common width is 6m. Compared with High density polyvinyl chloride root puncture resistant geomembrane, it can reduce welding cost in construction greatly.

- Q: How to measure the loss of geomembrane joints and related specifications?

- In general, the construction of the geotechnical membrane is mainly by welding, and the lap?width is confined to the requirements of the specification. According to the requirements of "the lap width of the sanitary landfill field seepage systems engineering and technical specifications CJJ113-2007 ", lap?width of geomembrane: sweat soldering: 100±20(mm) squeezing welding 75±20(mm). According to our factory's experience, in general, the overlap loss of the geomembrane is between the 5%-8%, that is, for each1000 square meters of geomembrane, the loss is 80 square meters to 50 square meters. Construction site whose environment is relatively simple can calculate the loss according to 5%, complex construction site can calculate the loss according to 8%.

Send your message to us

High Quality HDPE Textured and Perforated Geocell with Geomembrana PVC for Slope Protection, Mine Covering, Environment

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords