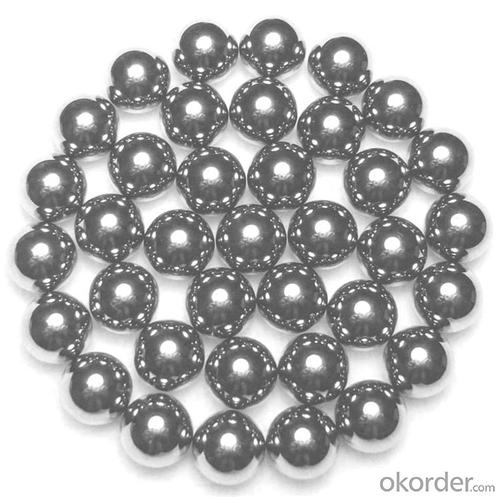

SUS304 Steel Shot Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

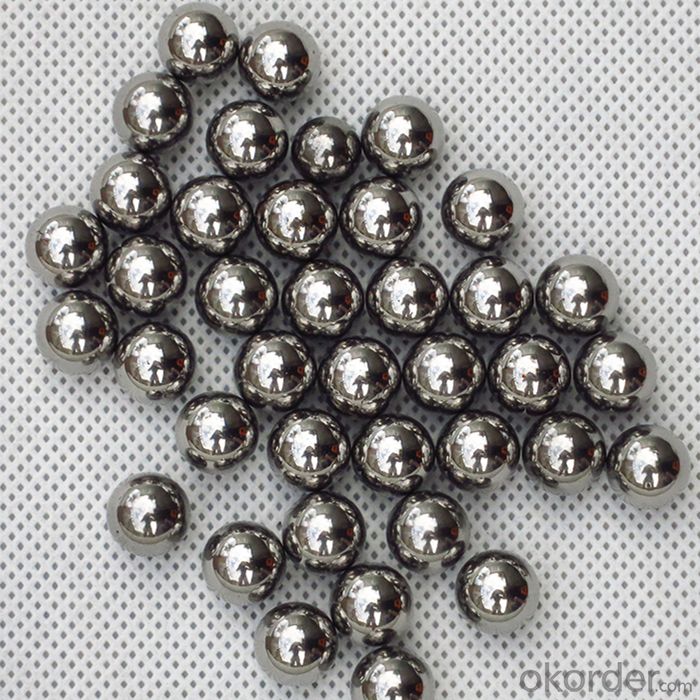

1, Chemical composition

304 Austenite Type (C)less than 0.25%, (Cr) 16-18%, (Ni) 6-10%, (Si)less than1%, (Mn)less than2%

430 Ferrite Type (C)less than0.25%, (Cr) 16-18%, (Si)less than1%, (Mn) less than1%

410 Martensite Type (C)less than 0.25%, (Cr)11-13%, (Si)less than1%, (Mn) less than 1%

2, Hardness1.0mm 51-53HRC 1.5mm 41-45HRC

Durability 6500 times

Microstructure:

304 Austenite Type Deformed Austenite

430 Ferrite Type Deformed Ferrite

410 Martensite Type Deformed Martensite

Density 7.8g/cm3

Bulk dendity 4.7g/cm3

Stainless steel shot production standards:

We strictly according to Japan JIS standard production stainless steel wire ingredients to production of sandblasting, peen-forming cleaning with stainless steel pill.

Application:

Stainless steel shot removing rust: Shot blasting rust-removal, shot peening rust-removal casting parts rust-removal, forged parts and steel plate rust-removal, H-beam steel rust-removal, steel structure rust-removal.

Stainless steel shot intensifying: Shot blasting intensifying of stainless steel parts and heat treatment parts.

Stainless steel shot shot peening: Shot peening of Coloured aluminum, copper, magnesium die-casting and stainless steel.

Application Devices:

Stainless steel shot is kind of abrasive used for shot blasting machine, shot blasting equipment, shot peening machine, shot peening equipment, sandblasting machine, sandblasting equipments, steel material pretreatment production line, steel plate pretreatment production line, steel structure pretreatment production line.

Packing Types:

Braided bag packing, flexible container packing, stock packing, paper bag packing, barrel packing.

- Q: What are the different types of steel products used in the manufacturing of jewelry and accessories?

- There are several types of steel products commonly used in the manufacturing of jewelry and accessories. These include stainless steel, surgical steel, and carbon steel. Stainless steel is a popular choice due to its durability, corrosion resistance, and affordability. Surgical steel, often used in body jewelry, is hypoallergenic and resistant to tarnish. Carbon steel, though less common, is sometimes used for its strength and unique aesthetic appeal.

- Q: How is steel wire rope manufactured?

- Steel wire rope is manufactured through a process called wire drawing, where steel rods are drawn through a series of dies to reduce their diameter. These drawn wires are then laid into strands and twisted together to form a rope. The strands are usually twisted around a central core to provide additional strength and stability. The finished steel wire rope is then subjected to various heat treatments and coatings to enhance its durability and resistance to corrosion.

- Q: What are the common types of steel products used in the fitness and sports industry?

- The common types of steel products used in the fitness and sports industry include dumbbells, barbells, weight plates, weightlifting racks, exercise machines, and sports equipment such as goal posts and basketball hoops.

- Q: How is steel rebar reinforced in concrete structures?

- Steel rebar is reinforced in concrete structures by placing it in strategic locations within the concrete. The rebar is typically shaped into bars or grids and is then placed in the formwork before the concrete is poured. This allows the rebar to provide additional strength and support to the concrete, making the structure more resistant to tension and bending forces.

- Q: How is steel sheet metal stamped for automotive parts?

- Steel sheet metal is typically stamped for automotive parts using a process called metal stamping. This involves placing a sheet of steel between two dies and applying immense pressure to form the desired shape. The dies have the desired shape of the automotive part, and the pressure from hydraulic or mechanical presses forces the steel sheet to conform to the shape of the dies, resulting in the stamped automotive part.

- Q: How is steel used in the construction of sports facilities?

- Steel is commonly used in the construction of sports facilities due to its strength and durability. It is used to create the framework of the structures, such as the supports for roofs and walls. Steel is also used in the construction of bleachers, seating areas, and staircases. Its versatility allows for the creation of large, open spaces, ensuring the safety and comfort of spectators. Additionally, steel's resistance to corrosion makes it suitable for outdoor sports facilities, as it can withstand harsh weather conditions.

- Q: How are steel products used in the oil and gas industry?

- Steel products are extensively used in the oil and gas industry due to their durability and strength. They are utilized in various applications such as pipelines, drilling equipment, storage tanks, and offshore structures. Steel pipes are used to transport oil and gas over long distances, while steel tanks provide storage for these resources. Additionally, steel is used in the construction of drilling rigs, platforms, and other offshore facilities, as it can withstand harsh environmental conditions. Overall, steel products play a crucial role in ensuring the safe and efficient extraction, transportation, and storage of oil and gas.

- Q: How is steel used in the production of construction machinery?

- Steel is commonly used in the production of construction machinery due to its high strength and durability. It is used to manufacture various components, such as frames, buckets, blades, and tracks, which require the ability to withstand heavy loads and harsh working conditions. Additionally, steel's malleability allows for easy shaping and forming of complex parts, enhancing the overall performance and reliability of construction machinery.

- Q: What are the challenges faced in the welding of steel products?

- Some of the challenges faced in the welding of steel products include achieving proper weld penetration, ensuring proper heat distribution, managing distortion and warping, dealing with welding fumes and safety hazards, and maintaining weld quality and integrity.

- Q: What are the different types of steel forgings and castings available?

- There are several different types of steel forgings and castings available, including open die forgings, closed die forgings, rolled ring forgings, investment castings, sand castings, and shell mold castings. These different processes result in steel components with varying shapes, sizes, strengths, and surface finishes, allowing for a wide range of applications in industries such as automotive, aerospace, construction, and manufacturing.

Send your message to us

SUS304 Steel Shot Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords