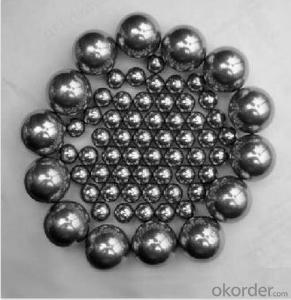

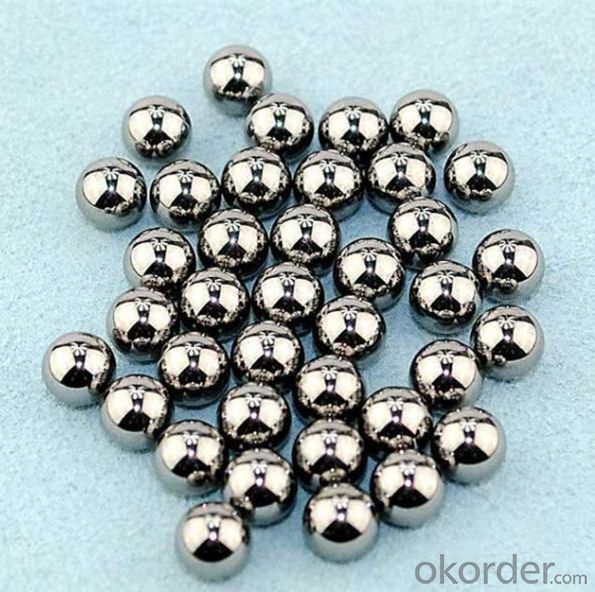

SUS304 Steel Shot 2mm-15mm Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

The detail of AISI304 stianless steel ball

Hereare many kinds of stainless steel balls, AISI 304, AISI 316, AISI 316L, AISI 420, AISI 420C,

AISI 440, AISI 440C.AISI 304 steel ballshave no good hardness but offer good corrosion resistance,

they offer good resistance to atomospheric corrosion, dyes, food processing, valves, sex products and so on.

AISI 304 stainless steel ball in our factory :

Minimum diameter: 2mm

Best precision :G100

Hardness :HRc25-39

| Product | SUS304 Steel Shot 2mm-15mm Chemical Product Stainless Steel Ball |

| Material | stainless steel |

| Brand | SAIGE |

| Percision | G100 |

| Hardness | HRC25-39 |

| Surface | zerodefect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

AISI 304 chemical Composition

| Materials Standard | Chemical Composition (%) | Hardness | ||||||

| JIS SUS304 (AISI304) (Din X5CrNi18-10) | C | Cr | Ni | Si | Mn | P | S | HRC25-39 |

| <0.08< td=""> | 18.00-20.00 | 8.00-10.50 | <1.0< td=""> | <2.0< td=""> | <0.045< td=""> | <0.030< td=""> | ||

PACKAGING

Type 1 : Plastic bag + box + carton + wooden pallet

Type 2 : Plastic bag + carton + wooden pallet

Type 3 : Our package :export cartons, steel drums, wooden pallets

- Q: How do steel products contribute to the construction of dams and reservoirs?

- Steel products play a vital role in the construction of dams and reservoirs due to their durability, strength, and versatility. Steel is used extensively in the structural components of dams, such as gates, spillways, and penstocks, as it can withstand high pressures and heavy loads. Additionally, steel reinforcement bars are incorporated into the concrete to enhance its tensile strength, ensuring the structure's stability. Steel sheets and plates are also employed for lining tunnels and creating watertight barriers. Overall, steel products provide the necessary strength and reliability required for the successful construction and long-term functionality of dams and reservoirs.

- Q: What are the different types of steel coatings and their applications?

- There are several types of steel coatings commonly used in various applications. These include galvanized coatings, which provide corrosion resistance and are commonly used in outdoor structures and automotive parts. Another type is powder coating, which offers durability and aesthetics, often applied to appliances, furniture, and architectural components. Additionally, epoxy coatings provide excellent chemical resistance and are used in industries like food processing and water treatment. Lastly, thermal spray coatings, such as metalizing or ceramic coatings, are applied to enhance wear resistance and thermal insulation in aerospace, automotive, and industrial applications.

- Q: How is steel sheet metal fabricated?

- Steel sheet metal is fabricated through a process called sheet metal forming, which involves cutting, bending, and shaping steel sheets into desired shapes and sizes using various tools and techniques like shearing, punching, welding, and folding.

- Q: What are the properties of stainless steel that make it corrosion-resistant?

- Stainless steel is corrosion-resistant due to its high chromium content, which forms a protective oxide layer on its surface. This oxide layer acts as a barrier, preventing the metal beneath from coming into contact with corrosive elements in the environment. Additionally, stainless steel also contains other alloying elements such as nickel and molybdenum, which enhance its corrosion resistance further.

- Q: How is steel used in the construction of theme parks and recreational facilities?

- Steel is a crucial material in the construction of theme parks and recreational facilities due to its strength, durability, and versatility. It is used for various structural elements such as roller coaster tracks, support beams, and framework for large-scale attractions. Steel's ability to withstand heavy loads and extreme weather conditions ensures the safety and stability of these structures, making it an essential component in creating thrilling and engaging experiences for visitors.

- Q: How do steel products contribute to the aerospace industry?

- Steel products contribute to the aerospace industry in multiple ways. Firstly, steel is used in the construction of aircraft frames and structural components, providing strength, durability, and resistance to high temperatures. Secondly, steel is vital in the manufacturing of jet engines, where it is used for turbine blades, casings, and exhaust systems due to its high heat resistance and excellent mechanical properties. Additionally, steel is utilized in aerospace fasteners, landing gear, and hydraulic systems, ensuring the overall safety and reliability of aircraft. Overall, steel products play a crucial role in enhancing the performance, efficiency, and safety of aerospace vehicles.

- Q: What are the different types of steel fencing and their applications?

- There are several types of steel fencing available in the market, each with its own unique features and applications. Some common types include ornamental steel fencing, chain-link fencing, welded wire fencing, and palisade fencing. Ornamental steel fencing is known for its decorative appearance and is often used to enhance the aesthetics of residential properties or public spaces. It is widely used in gardens, parks, and residential yards. Chain-link fencing, on the other hand, is a popular choice for many applications due to its affordability and durability. It is commonly used in commercial and industrial settings, as well as in residential properties for security purposes. Welded wire fencing is a versatile option that can be used for various applications, including agricultural enclosures, animal pens, and security fencing. It is known for its strength and can withstand harsh weather conditions. Palisade fencing is primarily used for high-security applications. Its design, consisting of vertical steel bars with pointed tops, makes it difficult to climb, providing excellent security for commercial and industrial properties. Overall, the choice of steel fencing depends on the specific needs and requirements of the project, whether it's for decorative purposes, security, or durability.

- Q: How is steel used in the railway industry?

- Steel is used extensively in the railway industry due to its strength and durability. It is used in the construction of railway tracks, bridges, and tunnels, as well as in the manufacturing of train components such as wheels, axles, and frames. Additionally, steel is used in the fabrication of locomotives and rolling stock, ensuring the safety and reliability of the railway system.

- Q: How are steel plates used in the fabrication of storage tanks?

- Steel plates are used in the fabrication of storage tanks as they provide a strong and durable material that can withstand the pressure and weight of the stored contents. The plates are cut and welded together to form the tank's structure, ensuring a secure and leak-proof container for storing various substances such as liquids or gases.

- Q: What are the safety precautions to be taken while using steel products?

- When using steel products, it is important to observe certain safety precautions. Firstly, it is crucial to wear appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. Additionally, one should ensure that the work area is well-ventilated to avoid inhaling harmful fumes or dust particles emitted during the use of steel products. It is also important to handle steel products with care, as they can be heavy and sharp, so proper lifting techniques and caution should be exercised to prevent strains or cuts. Finally, regular maintenance and inspection of steel products should be conducted to identify any potential hazards or signs of wear and tear, ensuring safe usage.

Send your message to us

SUS304 Steel Shot 2mm-15mm Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords