SUS304 Steel Shot 2mm Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

304

Certification:

ISO

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

Product Description

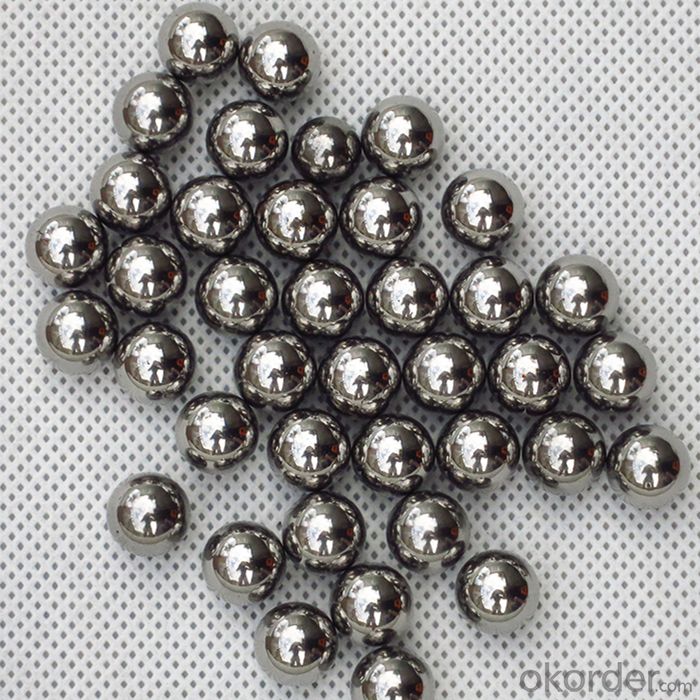

Stainless Steel Ball

1. Used in where good corrosion resistance is important, but hardness is not.

2. Offer good resistance to atmospheric corrosion, dyes, food environments, sterilizing solutions and many organic and inorganic materials.

| Stainless steel ball AISI 304 | ||||||||

| 1. Material | AISI 304/ SUS 304/ Wks 1.4301 | |||||||

| 2. Size Range | 1mm-180mm | |||||||

| 3. Grade | G40-1000 | |||||||

| 4. Hardness | 25-39 HRC | |||||||

| 5. Characteristic | (a)Good resistance to corrosion (b)Apply in where material toughness and resistance to corrosion are more important than hardness (c)Good corrosion resistance in the food environment, oxidizing solutions and most organic chemicals | |||||||

| 6. Magnetic | Much little | |||||||

| 7. Application | Valves, finger pumps, Aggressive applications without mechanical efforts | |||||||

| 8. Chemical composition | ||||||||

| C% | Si% | Mn% | Cr% | Ni% | P% | S% | N% | |

| min. | --- | --- | --- | 17.0 | 8.0 | --- | --- | --- |

| max. | 0.07 | 1.00 | 2.00 | 19.5 | 10.5 | 0.045 | 0.015 | 0.11 |

| 9.Packing | Standard: 10kg or 20kg per carton, 1 ton per pallet or as customer required | |||||||

| 10.Conditioning | dry or oiled | |||||||

| 11.Delivery time | Stock within a short time or 20 days. | |||||||

- Q: What are the different types of steel sheets and their uses in the packaging industry?

- There are several types of steel sheets used in the packaging industry, including tinplate, galvanized steel, and stainless steel. Tinplate is a thin steel sheet coated with a layer of tin, making it highly resistant to corrosion. It is commonly used for making food cans and beverage containers due to its ability to preserve the contents' freshness. Galvanized steel sheets are coated with a layer of zinc, which provides excellent rust resistance. They are often utilized for packaging materials that require durability and strength, such as metal drums and pails. Stainless steel sheets, known for their corrosion resistance and hygienic properties, are used in the packaging industry for applications like pharmaceutical packaging, cosmetic containers, and high-end food packaging.

- Q: What are the different types of steel forgings and their applications in the oil and gas industry?

- There are several types of steel forgings used in the oil and gas industry. Some common types include carbon steel forgings, stainless steel forgings, and alloy steel forgings. Carbon steel forgings are widely used due to their high strength and durability. They are commonly used in various applications such as valves, fittings, flanges, and pipelines. Stainless steel forgings are preferred for their corrosion resistance properties. They are commonly used in equipment and components that come in contact with corrosive substances, such as pumps, valves, and heat exchangers. Alloy steel forgings are known for their enhanced mechanical properties, including high strength, toughness, and resistance to wear and corrosion. They are commonly used in critical components such as drill bits, wellheads, and downhole tools. Overall, steel forgings play a crucial role in the oil and gas industry, providing reliable and efficient solutions for various applications, ensuring safe and efficient operations in this demanding sector.

- Q: How are steel products used in the chemical industry?

- Steel products are widely used in the chemical industry due to their durability, resistance to corrosion, and ability to withstand high temperatures and pressures. They are commonly used in the construction of chemical processing equipment such as tanks, pipelines, reactors, and storage vessels. Steel products also play a vital role in supporting and securing various chemical processes, ensuring the safe and efficient production of chemicals.

- Q: How is steel used in the manufacturing of elevators and escalators?

- Steel is used extensively in the manufacturing of elevators and escalators due to its strength, durability, and load-bearing capabilities. It is utilized in various components such as the elevator car, support structures, guide rails, and escalator steps. The steel framework provides the necessary stability, while its corrosion resistance ensures a long lifespan for these transportation systems.

- Q: How are steel bars used in the reinforcement of dams and reservoirs?

- Steel bars, also known as reinforcing bars or rebars, are commonly used in the reinforcement of dams and reservoirs. These bars are strategically placed and embedded within the concrete structure to enhance its strength and durability. By providing tensile strength, steel bars help prevent cracking and structural failure caused by extreme pressure or environmental factors such as water pressure and seismic activity. The steel bars also help to distribute and transfer loads evenly throughout the structure, ensuring its stability and longevity in the face of various external forces.

- Q: What are the uses of steel wire mesh?

- Steel wire mesh has a wide range of uses, including reinforcing concrete structures, providing security fencing, supporting plants in gardens, separating materials in industrial processes, and creating barriers for animal enclosures.

- Q: What are the properties of galvanized steel for outdoor applications?

- Galvanized steel is highly suitable for outdoor applications due to its exceptional properties. It possesses a protective zinc coating that prevents corrosion and rusting, ensuring durability and longevity even in harsh weather conditions. Additionally, galvanized steel exhibits excellent resistance against damage from UV rays, moisture, and various environmental factors, making it ideal for outdoor structures, fences, roofing, and other applications requiring reliable and long-lasting performance.

- Q: What are the common types of steel products used in the cosmetics and beauty industry?

- Common types of steel products used in the cosmetics and beauty industry include stainless steel tweezers, scissors, makeup brushes, and spatulas.

- Q: What are the different types of steel structural shapes?

- Some of the different types of steel structural shapes include I-beams, H-beams, channels, angles, and tubes. These shapes are commonly used in construction and engineering projects to provide structural support and stability.

- Q: How is steel tubing used in the production of furniture?

- Steel tubing is commonly used in the production of furniture as a structural component to provide strength and stability. It is often used in the construction of chair and table frames, as well as for making legs, supports, and other parts. Steel tubing offers durability and versatility, allowing for various design options and the ability to create sleek and modern furniture pieces.

Send your message to us

SUS304 Steel Shot 2mm Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords