4mm Steel Shot SUS304 Used Nail Polish Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

304

Certification:

ISO

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

Product Description

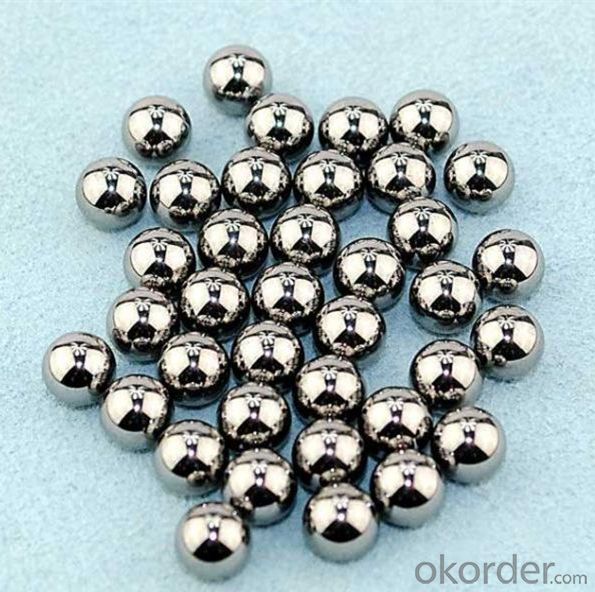

The detail of AISI304 stianless steel ballHereare many kinds of stainless steel balls, AISI 304, AISI 316, AISI 316L, AISI 420, AISI 420C,

AISI 440, AISI 440C.AISI 304 steel ballshave no good hardness but offer good corrosion resistance,

they offer good resistance to atomospheric corrosion, dyes, food processing, valves, sex products and so on.

AISI 304 stainless steel ball in our factory :

Minimum diameter: 2mm

Best precision :G100

Hardness :HRc25-39

| Product | 4mm Steel Shot SUS304 Used Nail Polish stainless Steel Ball |

| Material | stainless steel |

| Brand | SAIGE |

| Percision | G100 |

| Hardness | HRC25-39 |

| Surface | zerodefect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

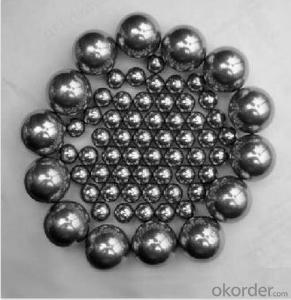

Products Picture

| Materials Standard | Chemical Composition (%) | Hardness | ||||||

| JIS SUS304 (AISI304) (Din X5CrNi18-10) | C | Cr | Ni | Si | Mn | P | S | HRC25-39 |

| <0.08 | 18.00-20.00 | 8.00-10.50 | <1.0 | <2.0 | <0.045 | <0.030 | ||

- Q: What are the common types of steel products used in the marine industry?

- The common types of steel products used in the marine industry include structural steel, marine grade stainless steel, and steel plates for shipbuilding.

- Q: What are the applications of steel in the chemical industry?

- Steel is widely used in the chemical industry due to its excellent properties such as corrosion resistance, high strength, and durability. It is used for various applications including storage tanks, pipelines, reactors, and equipment used in the production and transportation of chemicals. Steel's ability to withstand harsh chemical environments and high temperatures makes it an ideal material for these applications, ensuring the safety and efficiency of chemical processes.

- Q: How do steel products contribute to the construction of theme-based adventure parks?

- Steel products play a crucial role in the construction of theme-based adventure parks due to their strength, durability, and versatility. Steel is used in the framework and support structures of roller coasters, water slides, and other thrill rides, ensuring the safety and stability of these attractions. Additionally, steel is used in the fabrication of various park fixtures, such as entrance arches, railings, and signage, adding to the theme and aesthetics of the park. Overall, steel products provide the necessary infrastructure and creative elements that make theme-based adventure parks exciting and visually appealing.

- Q: What are the different types of steel rods and their applications?

- There are several types of steel rods commonly used in construction and manufacturing. Some common types include mild steel rods, stainless steel rods, carbon steel rods, and alloy steel rods. Mild steel rods are widely used due to their affordability and versatility. They are commonly used in general construction, reinforcement of concrete structures, and fabrication of fences and gates. Stainless steel rods offer excellent corrosion resistance and are used in applications where hygiene and aesthetic appeal are important, such as in food processing, pharmaceuticals, and marine environments. Carbon steel rods are known for their high strength and durability. They are commonly used in heavy-duty construction projects, such as bridges, high-rise buildings, and infrastructure. Alloy steel rods are made from a combination of different metals, offering specific properties such as increased strength, hardness, and resistance to wear and tear. They are often used in applications that require high performance, such as automotive parts, machinery, and tooling. Overall, the choice of steel rod depends on the specific requirements of the application, considering factors such as strength, corrosion resistance, cost, and environmental conditions.

- Q: How is steel used in the production of electrical equipment?

- Steel is used in the production of electrical equipment for various purposes such as housing, structural support, and protection. It is commonly used to manufacture enclosures, cabinets, and mounting brackets that provide a sturdy and secure housing for electrical components. Steel is also used to create structural frames for large electrical equipment like transformers and generators, ensuring stability and durability. Additionally, steel is utilized in the production of electrical equipment due to its ability to shield electromagnetic interference, protecting sensitive electronic components from external disturbances.

- Q: What are the common types of steel products used in the pet care and veterinary industry?

- Some common types of steel products used in the pet care and veterinary industry include stainless steel cages, surgical instruments, examination tables, and equipment such as scales and kennels.

- Q: What are the different types of steel reinforcement used in construction?

- The different types of steel reinforcement used in construction include steel bars (also known as rebars), welded wire mesh, and steel fibers.

- Q: What are the environmental impacts of producing steel products?

- The environmental impacts of producing steel products include emissions of greenhouse gases during the production process, such as carbon dioxide and methane. Steel production also contributes to air pollution through the release of particulate matter, sulfur dioxide, and nitrogen oxides. The extraction of raw materials for steel production, such as iron ore and coal, can result in habitat destruction and deforestation. Additionally, the energy-intensive nature of steel manufacturing leads to significant consumption of natural resources, including water and energy. Proper management and implementation of sustainable practices are crucial to minimize these environmental impacts.

- Q: How is steel used in the production of defense equipment?

- Steel is used in the production of defense equipment due to its strength, durability, and ability to withstand high temperatures and impact. It is commonly used in the manufacturing of armored vehicles, tanks, submarines, and various weapons, providing the necessary protection and structural integrity required for military applications.

- Q: How are steel tubes used in the fabrication of bicycle frames?

- Steel tubes are commonly used in the fabrication of bicycle frames because they provide strength, durability, and flexibility. These tubes are cut and shaped into various lengths and sizes, and then joined together using welding or brazing techniques to form the frame structure. The steel tubes allow for the creation of lightweight yet robust frames that offer excellent stability and performance while cycling.

Send your message to us

4mm Steel Shot SUS304 Used Nail Polish Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords