2mm-15mm SUS304 Steel Shot Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

304

Certification:

ISO

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

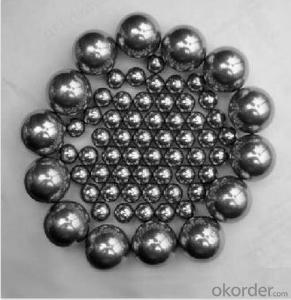

2mm-15mm SUS304 Steel Shot Stainless Steel Ball

The detail of 2mm-15mm SUS304 Steel Shot Stainless Steel Ball

Hereare many kinds of stainless steel balls, AISI 304, AISI 316, AISI 316L, AISI 420, AISI 420C,

AISI 440, AISI 440C.AISI 304 steel ballshave no good hardness but offer good corrosion resistance,

they offer good resistance to atomospheric corrosion, dyes, food processing, valves, sex products and so on.

AISI 304 stainless steel ball in our factory :

Minimum diameter: 2mm

Best precision :G100

Hardness :HRc25-39

| Product | 2mm-15mm SUS304 Steel Shot Stainless Steel Ball |

| Material | stainless steel |

| Brand | SAIGE |

| Percision | G100 |

| Hardness | HRC25-39 |

| Surface | zerodefect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

AISI 304 chemical Composition

| Materials Standard | Chemical Composition (%) | Hardness | ||||||

| JIS SUS304 (AISI304) (Din X5CrNi18-10) | C | Cr | Ni | Si | Mn | P | S | HRC25-39 |

| <0.08 | 18.00-20.00 | 8.00-10.50 | <1.0 | <2.0 | <0.045 | <0.030 | ||

The adventage of 2mm-15mm SUS304 Steel Shot Stainless Steel Ball

A, Safe Package

Step 1: Weighing stainless steel balls. Usually the weight is about 10kg.

Step 2: Sealed plastic bags

Step 3: Put sealed plastic bags into small boxes.

Step 4: Each box has the label, including material, Lot No. Size, quantity, grade, date and so on

Step 5: Each box directly put into mooden case.

High precision stainless steel balls usually is oil package. Normal precision stainless steel balls usually is dry package.

We also can pack them according to customers' request.

B,Sample free

If you are interested in our product , we can send you our free sample for you . Please contact us as soon as possible.

- Q: What are the different types of steel wire products?

- The different types of steel wire products include galvanized wire, stainless steel wire, spring wire, barbed wire, wire ropes, and wire mesh.

- Q: What are the different types of steel bars and their uses?

- There are several different types of steel bars, each with their own unique properties and uses. Some common types include mild steel bars, high-strength deformed bars, stainless steel bars, and alloy steel bars. Mild steel bars are widely used in construction for their affordability and versatility. High-strength deformed bars are commonly used in reinforced concrete structures to provide extra strength and durability. Stainless steel bars are corrosion-resistant and often used in applications where hygiene and aesthetics are important, such as in the food industry or architectural projects. Alloy steel bars, on the other hand, are made by adding various elements to enhance their strength, hardness, and resistance to wear. They find applications in machinery, automotive, and aerospace industries, among others. Overall, the choice of steel bar depends on the specific requirements of the project and the desired characteristics needed for its intended use.

- Q: How is stainless steel different from other types of steel products?

- Stainless steel is different from other types of steel products primarily due to its high resistance to corrosion and staining. It contains a minimum of 10.5% chromium, which forms a protective layer on the surface that prevents rusting and makes it highly durable. Additionally, stainless steel has excellent strength, heat resistance, and aesthetic appeal, making it a popular choice in various industries and applications.

- Q: How is steel rebar cut and bent for specific construction needs?

- Steel rebar is cut and bent for specific construction needs using specialized tools such as rebar cutters and benders. The rebar is measured according to the required length and then cut using the cutter. To achieve the desired shape, the rebar is then bent using a mechanical or hydraulic bender. This process ensures that the steel rebar is tailored to meet the specific requirements of the construction project, allowing for precise reinforcement and structural support.

- Q: What are the common uses of stainless steel cookware?

- The common uses of stainless steel cookware include cooking a variety of foods such as meats, vegetables, and sauces. It is also suitable for boiling, simmering, frying, and sautéing. Stainless steel cookware is known for its durability, heat conductivity, and non-reactive properties, making it ideal for everyday cooking in kitchens and professional settings.

- Q: What are the common types of steel products used in the e-commerce packaging industry?

- Common types of steel products used in the e-commerce packaging industry include steel strapping, steel banding, steel corner protectors, and steel shipping containers.

- Q: What are the advantages and disadvantages of using stainless steel products?

- The advantages of using stainless steel products include their durability, resistance to corrosion and staining, easy maintenance, and aesthetic appeal. Stainless steel is highly durable and can withstand high temperatures and harsh environments, making it ideal for various applications. Additionally, it is easy to clean and does not require special treatments or cleaning agents. Stainless steel products also provide an attractive and modern look. On the other hand, there are a few disadvantages to consider. Stainless steel products can be more expensive initially compared to other materials. They may also be heavier, which can be a drawback in certain applications. Additionally, stainless steel can show fingerprints and smudges more easily than other materials, requiring frequent cleaning. Lastly, stainless steel can be prone to scratching, although this can often be mitigated with proper care. Overall, the advantages of using stainless steel products generally outweigh the disadvantages, making it a popular choice in many industries and households.

- Q: How is steel wire rope inspected for safety?

- Steel wire rope is inspected for safety through a comprehensive process that includes visual inspections, non-destructive testing, and load testing. Trained inspectors carefully examine the rope for any signs of damage, such as broken wires, corrosion, or wear. Non-destructive testing techniques, such as magnetic particle inspection or ultrasonic testing, are used to detect internal flaws or defects that may not be visible to the naked eye. Finally, load testing is conducted to ensure the rope can handle the intended workload without any issues. Regular and thorough inspections are crucial to maintaining the safety and reliability of steel wire ropes in various applications.

- Q: What are the advantages of using steel in roofing materials?

- There are several advantages to using steel in roofing materials. Firstly, steel is known for its durability and strength, making it highly resistant to harsh weather conditions such as extreme temperatures, heavy rain, snow, and strong winds. This durability ensures that steel roofs have a longer lifespan compared to other roofing materials, reducing the need for frequent repairs or replacements. Additionally, steel roofs are fire-resistant, providing an extra layer of safety to the building. Steel is also lightweight, which makes it easier and cheaper to transport and install. Moreover, steel roofing materials are available in a variety of colors and styles, allowing for customization to match the aesthetic preferences of the building owner. Lastly, steel is an environmentally friendly choice as it is recyclable, reducing the impact on the environment and promoting sustainability. Overall, the advantages of using steel in roofing materials make it a popular and practical choice for many buildings.

- Q: How does steel pipe threading for plumbing applications work?

- Steel pipe threading for plumbing applications involves the process of cutting threads into the ends of steel pipes to create a tight and secure connection. This is typically done using a pipe threading machine that rotates the pipe while a cutting die is pressed against it, removing the material to form the threads. The threads on the pipes are usually tapered to ensure a tight seal when joined with fittings or other pipes. This method allows for easy installation and disassembly of plumbing systems, providing a reliable and leak-free connection.

Send your message to us

2mm-15mm SUS304 Steel Shot Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords