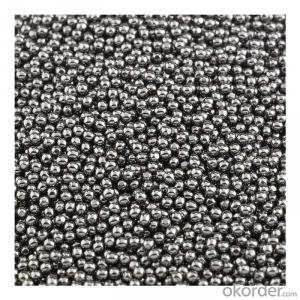

SUS420 G100 8mm Steel Shot SGS Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

420

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

Product Description

THE DETAIL OF STAINLESS STEEL BALL| Product | Stainless steel ball |

| Material | stainless steel |

| Brand | SAIGE |

| Percision | G100 |

| Hardness | HRC>52 |

| Surface | zero defect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

| Certification | ISO9100;2008SGS |

Products Picture

Stainless steel (AISI 420)

AISI 420 have good hardness and fair-to-good corrosion resistance and strength, it is generally used for all applications requiring resistance to corrosion such as bearings, valves, writting instruments, food environment, fresh water, many petroleum products and mild acid environments. AISI 420 is also magnetic.AISI 420 stainless steel balls in our factory:

Minimum diameter :1.2mm

Best precision :G10

Hardness :HRc>52

THE ADVENTAGE OF STAINLESS STEEL BALL

A, The strict process of stainless steel ball

Raw material--Wire drawing--Cold heading--Flashing--Heat treament--Grinding--Lapping 1--Lapping2--Lapping3--Washing--Checking. All balls must be passed the procedure of passivation. Each procedure have professional inspector. They will check steel balls each two hours to be sure correct diameter and good surface.

B, Sample Free

If you are interested in our product ,we can send you our free sample for you . Please contact us as soon as possible.

- Q: How do steel products contribute to the hospitality and tourism industry?

- Steel products contribute to the hospitality and tourism industry in various ways. Firstly, steel is an essential material for constructing hotels, resorts, and other hospitality establishments. Its strength, durability, and versatility make it ideal for creating sturdy and aesthetically pleasing structures that can withstand the demands of the industry. From the framing of the building to the interior fixtures and fittings, steel is used extensively, ensuring the safety and comfort of guests. Moreover, steel is used in the manufacturing of furniture, appliances, and amenities found in hotels and resorts. From beds, chairs, and tables to kitchen equipment, steel provides a reliable and long-lasting solution. Its corrosion resistance and easy maintenance make it an excellent choice for furnishings and equipment that can withstand the high usage and frequent cleaning requirements of the hospitality industry. Additionally, steel is crucial for the development of tourist attractions and infrastructure. From iconic landmarks and observation decks to bridges, railways, and transportation systems, steel plays a significant role in creating and maintaining tourist destinations. Its structural capabilities enable the construction of impressive architectural wonders and transportation networks that enhance the accessibility and appeal of tourism sites. In summary, steel products contribute significantly to the hospitality and tourism industry by providing durable and aesthetically pleasing infrastructure, reliable furnishings and equipment, and enabling the development of tourist attractions. Its strength, versatility, and low maintenance requirements make it an essential material that supports the growth and success of the industry.

- Q: What are the different types of steel tubes and their uses?

- There are several different types of steel tubes, each with its own specific uses. Some common types include carbon steel tubes, stainless steel tubes, alloy steel tubes, and galvanized steel tubes. Carbon steel tubes are most commonly used for general-purpose applications such as structural support or fluid transportation. Stainless steel tubes are known for their corrosion resistance and are commonly used in industries such as food processing, medical, and chemical. Alloy steel tubes are made from a combination of different metals and are used in high-temperature or high-pressure applications. Galvanized steel tubes have a protective zinc coating and are often used in outdoor or corrosive environments.

- Q: What are the applications of steel in the food processing industry?

- Steel is widely used in the food processing industry due to its various beneficial properties. It is commonly employed in the construction of machinery, equipment, and storage containers. Stainless steel, in particular, is highly resistant to corrosion, making it ideal for food contact surfaces and ensuring the safety and hygiene of food products. Additionally, steel's durability and strength make it suitable for heavy-duty applications such as food processing machinery, conveyors, and cutting tools. Overall, steel plays a crucial role in maintaining food quality, safety, and efficiency in the food processing industry.

- Q: What are the different types of steel products used in the manufacturing of musical instruments?

- There are several types of steel products used in the manufacturing of musical instruments, including stainless steel, carbon steel, and nickel-plated steel. Stainless steel is commonly used for instrument bodies and parts due to its corrosion resistance and durability. Carbon steel is often used for instrument springs, as it provides strength and flexibility. Nickel-plated steel is commonly used for guitar strings, as it enhances tone and increases longevity.

- Q: How do steel products contribute to the construction of theme-based adventure parks?

- Steel products play a crucial role in the construction of theme-based adventure parks due to their strength, durability, and versatility. Steel is used in the framework and support structures of roller coasters, water slides, and other thrill rides, ensuring the safety and stability of these attractions. Additionally, steel is used in the fabrication of various park fixtures, such as entrance arches, railings, and signage, adding to the theme and aesthetics of the park. Overall, steel products provide the necessary infrastructure and creative elements that make theme-based adventure parks exciting and visually appealing.

- Q: What are the common types of steel products used in the hospitality industry?

- The common types of steel products used in the hospitality industry include stainless steel kitchen equipment such as sinks, countertops, and shelves, as well as stainless steel cutlery, drinkware, and serving trays. Steel furniture like chairs, tables, and bar stools are also commonly found in hotels and restaurants. Additionally, steel door frames, security grills, and safety rails are used for security purposes in the hospitality industry.

- Q: How do steel products contribute to the mining and excavation industry?

- Steel products play a vital role in the mining and excavation industry by providing essential equipment and infrastructure. Steel is used to manufacture heavy machinery, such as excavators, bulldozers, and drilling rigs, which are crucial for extracting minerals and ores from the earth. Additionally, steel is used in the construction of mine shafts, tunnels, and support structures, ensuring the safety and stability of mining operations. Its durability and strength make steel products indispensable in this industry, enabling efficient and productive mining and excavation activities.

- Q: What are the common types of steel products used in the pet training and behavior industry?

- The common types of steel products used in the pet training and behavior industry include metal crates and kennels, leash hooks and hangers, training collars, prong collars, and various types of training and exercise equipment such as agility tunnels, jumps, and weave poles.

- Q: How do steel products contribute to the automotive racing industry?

- Steel products contribute to the automotive racing industry in various ways. Firstly, steel is used in the construction of race car frames, providing the necessary strength and rigidity to withstand high speeds and intense forces. Steel components such as suspension systems, brakes, and exhaust systems also enhance performance and safety. Additionally, steel is utilized in the manufacturing of race tracks, grandstands, and infrastructure, ensuring a secure environment for both drivers and spectators. Overall, steel products play a crucial role in advancing the performance, durability, and safety standards of the automotive racing industry.

- Q: What are the different types of steel structural shapes?

- Some of the different types of steel structural shapes include beams, channels, angles, and tubes. Beams are horizontal structural members that can support heavy loads. Channels are C-shaped sections that are used for various applications, such as framing and support. Angles are L-shaped sections that provide structural support and reinforcement. Tubes are hollow cylindrical structures that can be used for a variety of purposes, including construction and transportation.

Send your message to us

SUS420 G100 8mm Steel Shot SGS Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords