Sublimation Aluminum Sheets - Best Quality 0.3mm Roll from India Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

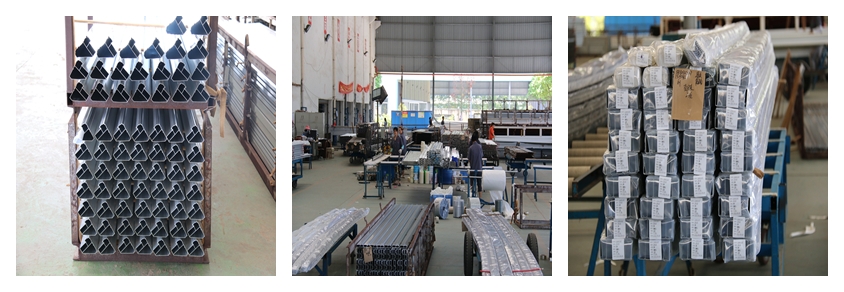

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

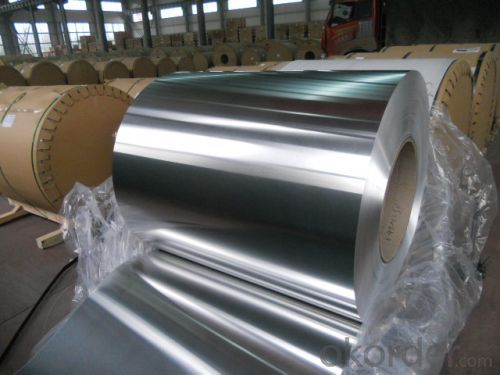

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: Can aluminum sheets be used for bus shelters?

- Yes, aluminum sheets can be used for bus shelters. Aluminum is a lightweight and durable material that can withstand harsh weather conditions, making it suitable for outdoor structures like bus shelters. Additionally, aluminum can be easily fabricated and customized to meet the specific design requirements of bus shelters.

- Q: As for cast aluminum sheet or wrought one, which one has faster heat conduction?

- 1,duralumin: it's the alloy of aluminum, copper, magnesium, manganese and other metals. it's suitable for compacting by rolling, and it has a higher strength and hardness than common aluminum products. 2, aluminum: it contains many inpurities, is crisp and easy to be smashed.cast aluminum usually is secondary aluminum, and it is produced by remelting the collected old aluminum pots and spoons.3, wrought aluminum: it contains 98% aluminum and 2% or more inpurities, and is comparatively pure aluminum. its soft priority makes it suitable for being pressed into various shapes, aluminum pots,aluminum lunch box,aluminum sheets,aluminum wires,aluminum pipes are all made by wrought aluminum.you will know their defferences from their definition.

- Q: Could induction heating fuenace be packaged with aluminum foil as insulation material?

- Aluminum foil can’t be used for heat retaining, it’s unsafe and hasn’t good efficiency. In this case, advice you use refractory cement to knot the coil and connect porcelain tube in the middle. It will Largely reduce the energy consumption produced by heat radiation.

- Q: How does the surface treatment of aluminum sheet affect its appearance?

- The appearance of aluminum sheet is greatly influenced by its surface treatment. Natural aluminum has a shiny and reflective surface, which can be improved or modified through different surface treatments. One popular surface treatment for aluminum sheet is anodizing, which involves the creation of a protective oxide layer on the surface through an electrochemical process. This treatment offers a wide range of colors and finishes, ranging from vibrant and opaque to translucent and metallic. Anodized aluminum sheets have a sleek and modern look, making them commonly used in architectural and decorative applications. Another option for surface treatment is painting or powder coating. These processes involve applying a layer of paint or powder onto the surface of the aluminum sheet. This treatment allows for customization in terms of color, texture, and finish. Painted or powder-coated aluminum sheets can have a smooth and glossy appearance or a textured and matte finish, depending on the desired outcome. This treatment is frequently utilized in industries like automotive, aerospace, and construction, where aesthetics and durability are important. Additionally, aluminum sheets can undergo mechanical surface treatments like brushing or polishing. Brushing involves creating parallel lines on the sheet's surface using abrasive pads, resulting in a brushed or satin finish. This treatment gives aluminum sheets a contemporary and industrial look. On the other hand, polishing involves buffing the surface to a high gloss and mirror-like finish. This treatment is often used for decorative purposes, such as in the production of jewelry or household items. In conclusion, the surface treatment of aluminum sheet plays a crucial role in determining its appearance. Whether it is anodizing, painting, powder coating, brushing, or polishing, each treatment offers a distinct visual effect that can enhance the aesthetic appeal of the aluminum sheet for specific applications and industries.

- Q: What is the hardness of aluminum sheets?

- The hardness of aluminum sheets may differ based on the particular alloy and temper it has undergone processing to. Aluminum alloys are usually evaluated using the Rockwell hardness scale or the Brinell hardness scale. Typically, pure aluminum exhibits a low hardness rating, approximately 20-30 on the Rockwell B scale, whereas certain aluminum alloys can achieve a hardness level of up to 70 on the Rockwell C scale. However, it is essential to recognize that the hardness of aluminum can be further adjusted through different heat treatment methods, like annealing or tempering, which can have a significant effect on its ultimate hardness.

- Q: i have a aluminum bicycle the first time i painted it i painted over the original paint(didnt know any better). The second time i sanded it down with some paint left on it. Now this time im sanding it but im using 60grit it looks good to me is 60 grit to much.

- Home or do-it-yourself spray jobs most of the time come out looking like - fill in word of your choice. Why? Because the person hasn't done their homework in advance. First, you will need to strip the bike down to the bare frame - remove everything. Are you qualified to do all of this? Do you have all the tools needed? The next best step would be to have the frame professionally sand blasted, powder-coated clear coated by possibly an auto body shop that does this kind of thing on the side. Can't do that? Consult Google link below. So much FREE information on the Internet, it's amazing.

- Q: Do the aluminum sheets come with a protective coating?

- Yes, the aluminum sheets come with a protective coating. The protective coating is applied to prevent scratches, corrosion, and other damages during transportation and handling. This coating ensures that the aluminum sheets are delivered to the customers in pristine condition.

- Q: How do aluminum sheets handle extreme temperatures?

- The exceptional ability of aluminum sheets to handle extreme temperatures is widely recognized. This is primarily due to their high thermal conductivity, which enables them to effectively dissipate heat. As a result, they are suitable for applications involving high temperatures. Aluminum, with a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), can withstand a wide range of extreme temperatures without compromising its structural integrity. When exposed to intense heat, aluminum sheets do not easily deform or warp. Consequently, they are ideal for use in environments with high temperatures, such as industrial furnaces, automotive engines, and aerospace applications. Furthermore, aluminum has a low coefficient of thermal expansion, meaning it expands and contracts minimally when subjected to temperature variations. This significantly reduces the risk of cracking or structural damage. On the contrary, aluminum also performs exceptionally well in extremely cold temperatures. It remains durable and retains its strength even in freezing conditions. This makes aluminum sheets suitable for cryogenic applications, including the construction of liquid natural gas tanks or aerospace components that operate in low-temperature environments. In conclusion, aluminum sheets excel in handling extreme temperatures due to their high thermal conductivity, low coefficient of thermal expansion, and excellent structural integrity. Whether subjected to intense heat or extreme cold, aluminum sheets remain stable and reliable, making them the preferred choice in various industries.

- Q: Can aluminum sheets be used in electrical applications?

- Yes, aluminum sheets can be used in electrical applications. Aluminum is a good conductor of electricity and is commonly used in electrical wiring, power transmission lines, and electrical enclosures.

- Q: What are the applications of aluminum sheet?

- Aluminum sheets have a wide range of applications due to their unique properties and versatility. Some of the common applications of aluminum sheets include: 1. Construction: Aluminum sheets are widely used in the construction industry for roofing, siding, and cladding purposes. Their lightweight nature makes them easy to handle and install, while their corrosion resistance ensures long-lasting durability. 2. Transportation: Aluminum sheets are extensively used in the automotive industry for manufacturing vehicle bodies, panels, and structural components. Their high strength-to-weight ratio helps reduce the overall weight of vehicles, increasing fuel efficiency and improving performance. 3. Packaging: Aluminum sheets are commonly used in the packaging industry for manufacturing cans, foils, and containers. Aluminum foils are used for food packaging, as they provide a barrier against moisture, light, and oxygen, ensuring the freshness and safety of the packaged products. 4. Electrical: Aluminum sheets are used in the electrical industry for manufacturing power transmission lines, busbars, and electrical enclosures. Their excellent electrical conductivity helps in the efficient transmission of electricity, while their corrosion resistance ensures longevity in outdoor applications. 5. Marine: Aluminum sheets are widely used in the marine industry for manufacturing boat hulls, decks, and superstructures. Their resistance to corrosion from saltwater makes them ideal for marine applications, while their lightweight nature helps reduce the overall weight of the vessel. 6. Aerospace: Aluminum sheets are extensively used in the aerospace industry for manufacturing aircraft and spacecraft components. Their high strength-to-weight ratio and excellent thermal conductivity make them suitable for applications where weight reduction and heat dissipation are critical. 7. Heat exchangers: Aluminum sheets are used in the manufacturing of heat exchangers, such as radiators and condensers. Their high thermal conductivity allows for efficient heat transfer, making them ideal for applications where heat exchange is required. 8. Decorative: Aluminum sheets are commonly used in interior design and architectural applications for decorative purposes. They can be easily shaped, bent, and formed into various designs, adding a modern and aesthetic appeal to buildings and interiors. Overall, aluminum sheets find applications in various industries due to their lightweight nature, corrosion resistance, high strength-to-weight ratio, and excellent thermal conductivity.

Send your message to us

Sublimation Aluminum Sheets - Best Quality 0.3mm Roll from India Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords