Steel Tile Roll Forming Machine with ISO

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 100 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

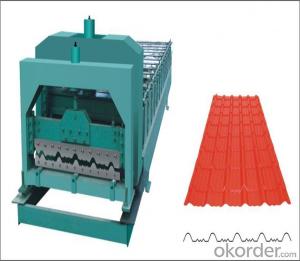

1.Structure of steel tile roll forming machine:

Steel tile roll forming machine consists of feeding, forming, after forming cutting production of color plate smooth appearance beautiful appearances, uniform lacquer veins, high strength, durable, widely used in industrial and civil buildings, such as workshop, warehouse, gymnasium, exhibition halls, theaters and other surface and wall.

2.Main Features of the steel tile roll forming machine:

The tile roll forming machine has the advantages of good corrosion resistance, colorful, beautiful appearance, convenient processing molding and the advantages of the the original strength of the steel plate and the cost is low.

First generation and second generation "automatic moulding color tile equipment" adopt "swinging cylinder driving sliding table", "swinging cylinder" belong to "moulded caigang watts equipment" is "extremely fragile" in accessories, if the forming speed is too fast, cause a large sliding table shock, buffer vibration easily, cause the tiles have crack, is the first and the second generation "stubborn" in the color tile equipment. So the fastest forming up to 6 pieces per minute.

3.Steel tile roll forming machine Images

4.Steel tile roll forming machine Specification

Steel tile roll forming machine has a lot of parameters to set, by using the text screen or touch screen setting. Parameter setting, which has two kinds of equipment parameters and user setting.

Equipment parameters: single pulse length, impulse, molding, molding time, cutter and so on.

User parameters: the number, length, pitch, the first section, small section, section number, preloading and so on.

Main moter power 5.5KW

Hydraulic station power 4KW

Hydraulic oil pump CB-E310

Sprocket P-25.4

Roller station 13

Yield strength 32MPa

Diameter of principal axis 90MM

Material of roller 45#steel hard chrome plating

Processing speed 10-15m/min

Thickness 0.3-1.2 mm

Installation dimension about(L*W*H) 7.5*1.3*1.5M

Total weight 4.2T

Equipment parts includes:roll forming system, hydraulic system, PLC frequency conversion control system, counter, cutting system,decoiler .

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1). What’s your machine installation & commissioning, training:

1or2 technicians will be dispatched to Buyer’s plant for installation & commissioning. Work period: in 5 days. The expense of round trip tickets, accommodation, safety and interpretation shall be covered by Buyer, additional pay allowance to the technicians.

2). Can you make machine according to my design?

Yes, we have experienced technical team to work out the suitable design for you and confirm with you until you agree.

3). What is the warranty for our machine?

We have one year guarantee, and provide whole life's technical support.

4).Is the machine automatic?

Yes, it can be manual and automatic.

5).what policy for broken parts?

within one year,we offer free parts. If beyond one year,you need to buy by factory cost

- Q: What are the pros and cons of a concrete mixer?

- Are you talking about the production line at the blender station or is it the usual blender or that? These I understand

- Q: A concrete mixer can last for years

- Are now commonly commercial concrete mixing plant mixing unit, use fixed number of year of the requirements, without proclaimed in writing if repair, maintenance and so on is good, can satisfy the production requirement, fixed number of year can reach more than 10 years.

- Q: How many tiles are in the concrete mixer on the site

- The power of the mixer motor on the site is 75KW

- Q: What is the difference between a concrete mixer and a mortar mixer

- Concrete is made by mixing several kinds of aggregates and water, cement and mixing. Because of containing coarse aggregate, and therefore require huge stirring power, also requires wear-resisting, so his stirring blades and liner is high chromium cast iron, or pieces, power is big, like JS500 will be 18.5 kw motor to drive! And the mortar is not contain coarse aggregate, so the power is very small, the power consumption is very low, do not need wear-resisting piece, appear easy and clever!

- Q: How the concrete mixer works

- Mixed mortar mixer working principle of the machine work, inside the machine material subjected to two opposite direction of the rotor, with complex movement, the blades to drive the material aspects of tank wall along the machine counterclockwise, on the one hand, drive material turning around, overlapping the two rotor shape floating zone, within the region, regardless of the shape of the material, size, and density, can make material floating instant weightlessness, which makes the material in the machine groove omni-directional continuous loop turn, staggered shear each other, so as to achieve the effect of rapid mixing soft. Vacuum mixer manufacturer said, dual-axis mixer for continuous mixing of materials, mixing and conveying function, its working process is: the motor after electrify, through a triangle belt transmission, the big belt wheel rotation, through controlling the clutch into the working state, drives the stirring shaft of two relative rotation, the direction of the two shaft rotates by outside introversion, material is stirred up, formed by mixing blade rotates thrust material flow, spiral forward, into the mixing of the material for stirring, mixing, extrusion, homogenization, the final material to undertake by the leak container into the belt, and finally to the next processing equipment. The mixing of the material in the mixing tank shall be determined mainly by the Angle of the stirring and the Angle of the axis and the speed of the shaft.

- Q: Common type of concrete mixer

- The common concrete mixer is divided into two kinds: self-falling concrete mixer and strong concrete mixer.

- Q: Operation procedure of concrete mixer

- Safety procedure of concrete mixer A blender must be placed in a solid place, secured with a bracket or a leg holder, and no tires should be replaced. Before starting the mixer, the clutch, brake, wire rope and so on should be checked, and no foreign material in the roller. When the hopper is hoisted, no one shall pass or stay in the hopper, and the hopper shall be fixed after the work is completed. When running, it is strictly forbidden to put the tool into the roller. It is strictly forbidden to leave the work station without any evidence of operation or operation. When repairing, should fix the hopper, cut off the power supply. After the work is finished, should clean the fuselage concrete, do the lubrication to maintain, cut off the power to lock the door.

- Q: How much concrete the concrete mixer can stir at a time

- 350-concrete mixer is a double conical turning out of the feed mixer, and the plastic and semi-dry hard concrete of 60 mm. Stirring when the mixer is turning, and automatically when reversing. Each can be mixed with concrete 0.35 cubic meters. Depending on the size of the concrete, the amount of cement used varies.

- Q: Can you stir the mortar in a concrete mixer?

- The blender is completely whipping the mortar. no problem,thank you

- Q: What is the difference between a concrete mixer, a JL type and a JW type?

- The jw-375 concrete mixer is a turbo-reinforced concrete mixer, which is used for hard and semi-dry concrete. The main body of this mixer consists of the frame, the feeding system, the mixing system, the water supply system, the control device and the transmission mechanism.

Send your message to us

Steel Tile Roll Forming Machine with ISO

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 100 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords